Description

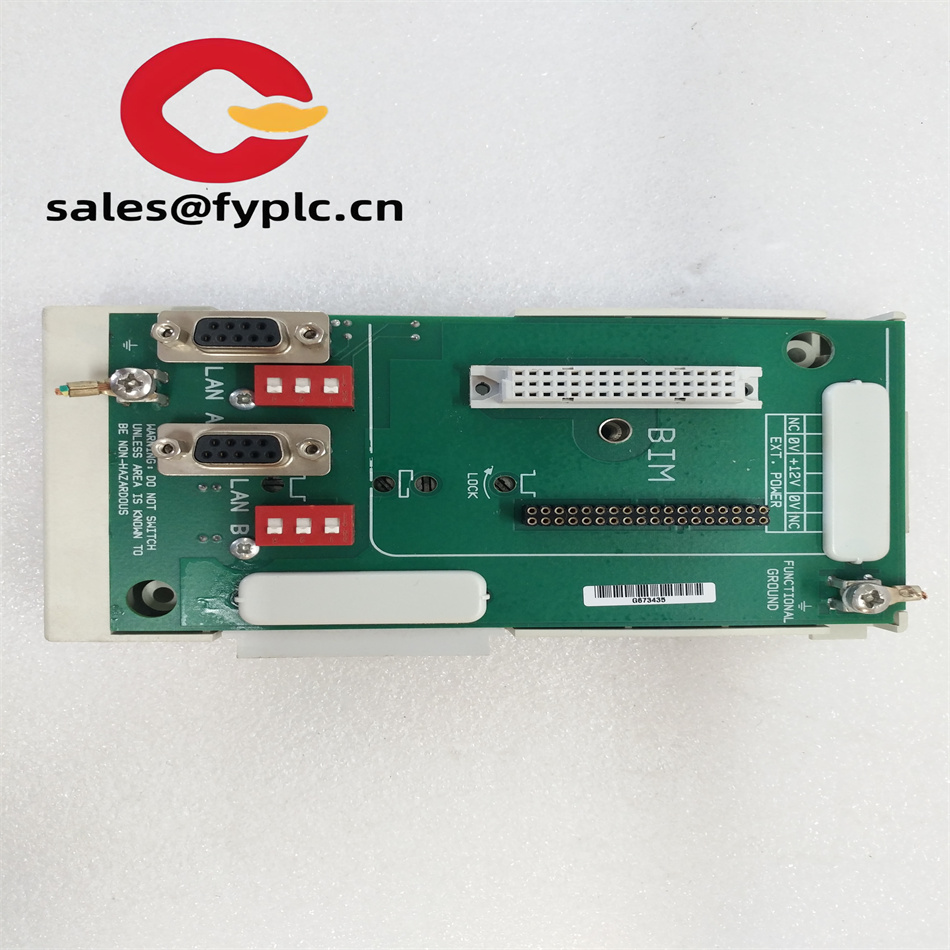

MTL 8715-CA-BI Analog Signal Grid Bus Interface Module

In the complex and safety – critical realm of industrial automation, the MTL 8715 – CA – BI emerges as a highly specialized and indispensable device. Engineered with precision and reliability in mind, this advanced module is designed to meet the stringent demands of modern industrial environments, providing a comprehensive solution for signal isolation, processing, and control. Whether deployed in oil and gas refineries, chemical plants, or other industries where hazardous conditions prevail, the MTL 8715 – CA – BI plays a pivotal role in ensuring the seamless operation of industrial processes while safeguarding against potential risks.

The MTL 8715 – CA – BI is a galvanically isolated analog signal interface module, primarily designed to interface between control systems and field devices. Its core function lies in isolating and processing analog signals, ensuring that electrical interference and potential hazards are effectively mitigated, while maintaining the integrity of the transmitted data. This makes it an essential component in industrial control systems, where the accurate and reliable transmission of signals is crucial for the proper functioning of the entire system.

Functional Strengths and Design Advantages

Signal Isolation

One of the standout features of the MTL 8715 – CA – BI is its exceptional signal isolation capabilities. By effectively separating the input and output circuits, it prevents interference from traversing between them. This is of utmost importance in industrial environments, where electrical noise and interference can easily disrupt the accuracy of signal transmission. For example, in a chemical plant with numerous high – power motors and electrical equipment in operation, the MTL 8715 – CA – BI can isolate the delicate sensor signals from the noisy electrical environment, ensuring that the control system receives accurate and reliable data. This not only enhances the stability of the industrial automation system but also reduces the likelihood of false readings and system malfunctions.

Analog Signal Transmission

Designed specifically for the isolation and transmission of 4 – 20 mA analog signals, the module offers great flexibility in adapting to different application scenarios. The input signal of 4 – 20 mA DC is a standard in many industrial sensors, and the MTL 8715 – CA – BI can efficiently process and transmit this signal. It can output either a 4 – 20 mA DC signal or convert it to a 1 – 5V DC signal, depending on the requirements of the connected equipment. In a wastewater treatment plant, sensors measuring parameters such as pH levels, dissolved oxygen, and flow rates often use 4 – 20 mA signals. The MTL 8715 – CA – BI can take these input signals, isolate them, and then transmit them in the appropriate format to the control system, enabling precise monitoring and control of the treatment process.

Digital Quantity Control

As a digital quantity control module, the MTL 8715 – CA – BI comes equipped with 8 digital quantity input ports and 4 digital quantity output ports. These ports provide a versatile means of connecting various sensors and actuators. The input ports can be connected to sensors such as proximity switches, limit switches, and pushbuttons, allowing the module to receive digital signals indicating the status of different components in the industrial process. The output ports, on the other hand, can be used to control actuators like relays, solenoid valves, and motors. In an automated manufacturing assembly line, the digital input ports can detect the presence of components on conveyor belts, and the digital output ports can then activate robotic arms or other actuators to perform assembly operations, ensuring smooth and efficient production.

High – Quality Build

Constructed using high – grade materials, the MTL 8715 – CA – BI is built to withstand the harsh conditions commonly found in industrial settings. It is resistant to factors such as moisture, dust, and chemical corrosion, ensuring long – term reliability and stability. This robust build quality minimizes the need for frequent maintenance or replacement, reducing downtime and overall operational costs. In a food processing factory, where the environment may be humid and prone to the presence of food particles and cleaning chemicals, the MTL 8715 – CA – BI can continue to operate reliably, maintaining the integrity of the control system.

Compatibility

The module’s compatibility with a wide range of industrial instruments and control systems makes it a versatile choice for engineers. It can seamlessly integrate with existing setups, whether they are based on different brands of control systems or a variety of field devices. This interoperability simplifies the process of system expansion and upgrade. For instance, when a power generation plant decides to add new sensors or actuators to its control system, the MTL 8715 – CA – BI can be easily incorporated without major re – engineering, enhancing the overall functionality of the system.

Diagnostic Capabilities

The MTL 8715 – CA – BI features module and channel status extension diagnostic functions. This allows users to quickly identify and troubleshoot any issues that may arise. In case of a signal loss or an abnormal reading, the diagnostic function can pinpoint the source of the problem, whether it is a faulty sensor, a damaged cable, or an issue with the module itself. In a large – scale industrial complex, where multiple sensors and actuators are interconnected, this diagnostic capability can save valuable time and resources in maintaining the smooth operation of the control system.

Industrial Use Cases

Oil and Gas Industry

In the oil and gas sector, safety and reliable signal transmission are of paramount importance. The MTL 8715 – CA – BI is extensively used to interface between control systems located in safe areas and field devices in hazardous zones. It can connect sensors that monitor parameters such as pressure, temperature, and gas composition in oil wells, pipelines, and refineries. By isolating the signals from the potentially explosive environment, it ensures that the control system can accurately monitor and control the operations without posing a safety risk. In an offshore oil rig, for example, the module can receive signals from sensors placed in areas where flammable gases may be present and transmit them safely to the control room, enabling operators to make informed decisions regarding production and safety measures.

Chemical Industry

Chemical plants rely on precise process control to ensure product quality and safety. The MTL 8715 – CA – BI plays a crucial role in maintaining the integrity of process control systems. It can transmit signals from sensors that monitor variables such as temperature, pressure, and chemical concentrations in reactors, distillation columns, and storage tanks. By accurately processing and transmitting these signals, it enables the control system to regulate chemical reactions, adjust flow rates, and ensure that the production process adheres to strict quality and safety standards. In a petrochemical plant, the module can help control the polymerization process in a reactor by precisely transmitting signals related to temperature and pressure, ensuring the production of high – quality polymers.

Pharmaceutical Industry

In the pharmaceutical industry, where the production process must meet strict quality and regulatory requirements, the MTL 8715 – CA – BI is used to connect control systems with various process equipment. It can ensure the accurate transmission of signals related to parameters such as flow rates, pH levels, and sterilization conditions. In a pharmaceutical manufacturing facility, sensors monitoring the flow rate of raw materials during the production of medications can be connected to the module. The MTL 8715 – CA – BI then transmits this signal to the control system, which can adjust the flow rate to ensure consistent product quality. Its signal isolation capabilities also prevent any electrical interference from affecting the sensitive production process.

Power Generation

Power plants, whether they are coal – fired, gas – fired, or nuclear, require reliable control systems to ensure stable power generation. The MTL 8715 – CA – BI can be used to interface between control systems and sensors that monitor the performance of generators, turbines, and other critical equipment. It can transmit signals related to parameters such as voltage, current, and rotational speed. In a wind farm, for example, the module can connect sensors on wind turbines that measure wind speed, blade angle, and generator temperature. By accurately transmitting these signals to the control system, it enables operators to optimize the performance of the wind turbines and ensure efficient power generation.

Related Models

MTL 8716 – CA – BI

The MTL 8716 – CA – BI offers enhanced signal processing capabilities compared to the MTL 8715 – CA – BI. It may be equipped with more advanced algorithms for signal conditioning, filtering, and calibration. This makes it suitable for applications where extremely accurate and noise – free signal processing is required, such as in high – precision scientific research equipment or in industries where minute signal variations can have a significant impact on the production process, like in the semiconductor manufacturing industry.

For more information, please click below to learn more:

Reviews

There are no reviews yet.