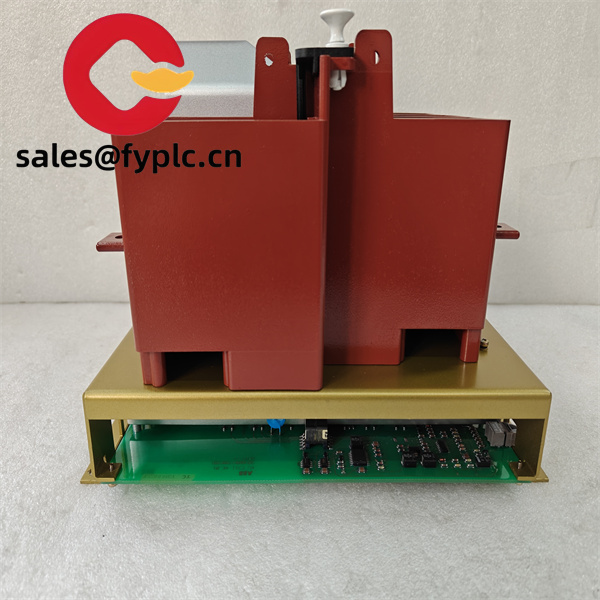

ABB 3BHB004661R0101 power drive module board

| Model Number | 3BHB004661R0101 |

| Brand | ABB |

| Type | Multifunctional Module (with applications in control and power systems) |

| Input Voltage | Typically designed to operate within a wide voltage range, such as 85 – 264V AC, to accommodate different industrial power supplies |

Categories: ABB

Need help?

Email: sales@fyplc.cn

Tel/WhatsApp: +86 173 5088 0093

Description

ABB 3BHB004661R0101 power drive module board

In the intricate domain of industrial automation, ABB’s 3BHB004661R0101 emerges as a pivotal component, designed to optimize and streamline operations across diverse industrial applications. Engineered by the globally revered ABB, a leader in power and automation technologies, the 3BHB004661R0101 serves as a multifunctional module with applications spanning multiple industries.

One of its primary applications is in industrial control systems, where it acts as a crucial link in coordinating the operation of various components. In manufacturing plants, for example, it can be integrated into production line control systems. Here, it receives signals from sensors that monitor product quality, machinery status, or production rates. By processing these signals, it can then send out control commands to actuators, such as motors or robotic arms, ensuring smooth and efficient production. In a food packaging factory, sensors might detect the presence of a product on the conveyor belt. The 3BHB004661R0101 module would receive this signal, process it, and then trigger the packaging machinery to seal the package, maintaining the production flow.

In power generation and distribution, the 3BHB004661R0101 plays a vital role. In power plants, it can be part of the excitation control system for generators. For synchronous generators, a stable and precisely controlled excitation current is essential to regulate the output voltage and power factor. The 3BHB004661R0101, when configured as part of the excitation system, can accurately adjust the excitation voltage and current. It monitors parameters such as the generator’s terminal voltage and load current. If the terminal voltage starts to deviate from the set value due to changes in the electrical grid or load demand, the module can calculate the necessary adjustments and control the power electronics in the excitation system to correct the voltage, ensuring a stable power supply to the grid.

Technical Highlights Table

| Label | Specification |

|---|---|

| Model Number | 3BHB004661R0101 |

| Brand | ABB |

| Type | Multifunctional Module (with applications in control and power systems) |

| Input Voltage | Typically designed to operate within a wide voltage range, such as 85 – 264V AC, to accommodate different industrial power supplies |

| Operating Temp | Has an operating temperature range of – 10°C to 55°C, suitable for a variety of industrial environments, from cold storage facilities to hot manufacturing workshops |

| Communication Method | Supports popular industrial communication protocols like Modbus, Profibus – DP, and Ethernet. Modbus allows for reliable data transfer between the module and other Modbus – compatible devices, such as sensors and actuators. Ethernet enables high – speed data exchange, facilitating real – time monitoring and control in larger industrial networks |

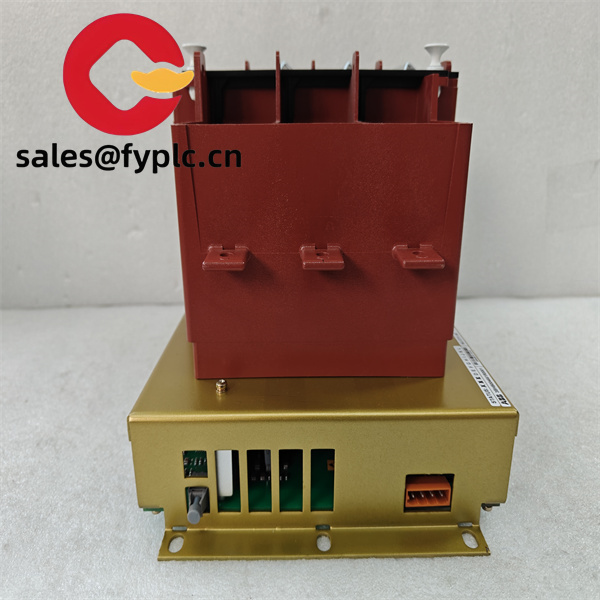

| Mounting | Designed for easy installation, often with a DIN – rail mounting option. This allows for quick and secure attachment within standard industrial control panels, minimizing installation time and effort |

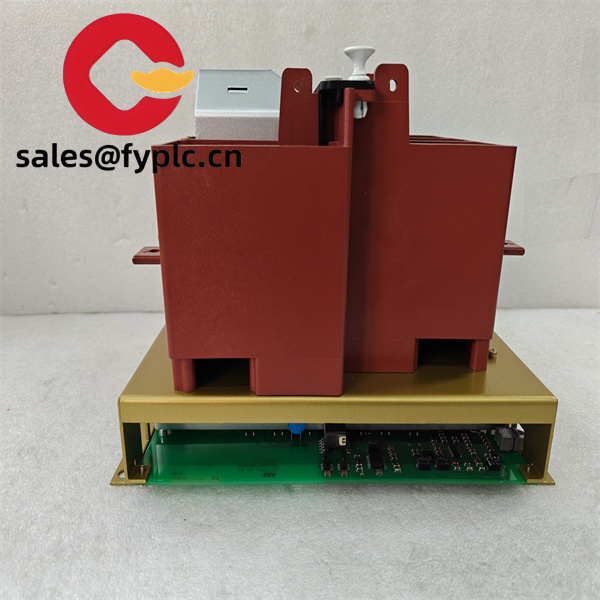

| Weight | Approximately 1.08 kg, which is lightweight enough for easy handling during installation and maintenance, yet robust enough to withstand industrial vibrations and mechanical stress |

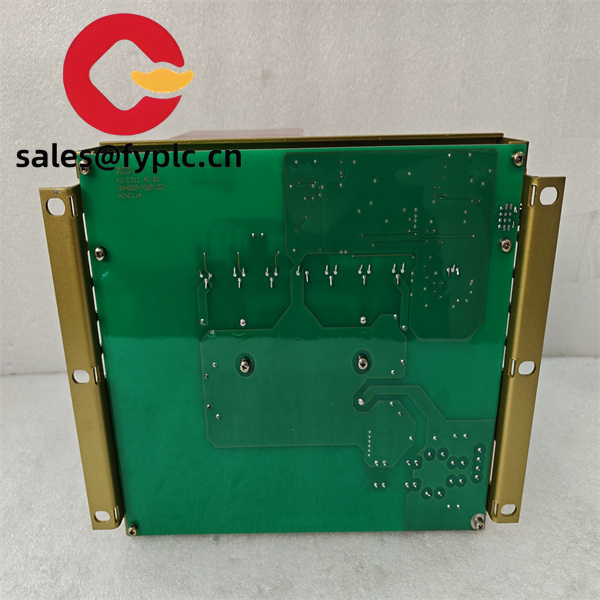

| Certifications | Complies with international safety and quality standards such as IEC 61131 – 2. This certification ensures that the module meets strict requirements for electrical safety, electromagnetic compatibility, and performance in industrial applications |

| Dimensions | With dimensions of approximately 140 mm (Length) x 240 mm (Width) x 350 mm (Height), it is compact enough to fit into standard – sized control enclosures, maximizing space utilization in industrial control setups |

| Digital I/O | Equipped with a significant number of digital input and output channels. For instance, it may have 32 digital inputs and 32 digital outputs. These channels can be used to interface with digital sensors (such as proximity switches, limit switches) and digital actuators (such as relays, solenoid valves), enabling comprehensive control of digital – based industrial processes |

| Analog I/O | Features a set of analog input and output channels, perhaps 8 analog inputs and 8 analog outputs. This allows it to interface with analog – based sensors (like temperature sensors, pressure transducers) and analog – controlled devices (such as variable – speed drives), expanding its application scope in industrial processes that require precise analog signal handling |

| Redundancy Features | In some configurations, it may offer redundancy features, such as dual – power inputs or redundant communication channels. Dual – power inputs ensure continuous operation even if one power source fails, while redundant communication channels enhance the reliability of data transfer, reducing the risk of communication failures in critical industrial applications |

Functional Strengths & Design Advantages

The ABB 3BHB004661R0101 has been engineered with a focus on delivering high – performance functionality. Its powerful data processing capabilities enable it to handle a large volume of input data in real – time. In high – speed production lines, where rapid decision – making based on sensor data is crucial, the module can quickly analyze incoming signals from multiple sensors. For example, in an automotive assembly plant, it can simultaneously process data from sensors monitoring the position of parts, the torque of robotic arms, and the speed of conveyor belts. Based on this analysis, it can send out control signals to adjust the operation of various components within milliseconds, ensuring seamless production flow and high – quality assembly.

The build quality of the 3BHB004661R0101 is exceptional. Constructed with high – grade materials, it can endure the harsh conditions prevalent in industrial settings. It is highly resistant to electrical interference, which is common in industrial environments filled with motors, transformers, and other electrical equipment. The module can also withstand vibrations from heavy machinery and temperature fluctuations without any significant impact on its performance. This durability ensures long – term reliable operation, minimizing maintenance requirements and production downtime. Its design also emphasizes compatibility and ease of integration. Whether it’s connecting to new – generation industrial sensors or interfacing with existing control systems, the 3BHB004661R0101 ensures smooth communication and seamless operation. It can be easily configured to work with different types of industrial devices, making it a versatile choice for industrial automation projects.

Industrial Use Cases & Value Scenarios

The ABB 3BHB004661R0101 finds extensive application in various industrial sectors. In the manufacturing industry, it is widely used in production line control. In a textile mill, for example, the module can control the operation of spinning machines, looms, and other equipment. Sensors placed on the machines can detect parameters such as yarn tension, fabric quality, and machine speed. The 3BHB004661R0101 receives these sensor signals, analyzes them, and then sends control commands to adjust the machine settings. If the yarn tension is too high, it can control the motor speed to reduce the tension, ensuring high – quality fabric production. By optimizing the operation of these machines, it helps to improve production efficiency, reduce waste, and enhance product quality.

In the power generation and distribution industry, the module plays a crucial role in ensuring the stability and reliability of the power supply. In a wind power plant, the 3BHB004661R0101 can be part of the pitch control system for wind turbines. Wind speed and direction are constantly changing, and the pitch of the turbine blades needs to be adjusted to optimize power generation. Sensors on the turbine measure the wind speed and direction, and the 3BHB004661R0101 processes this data. It then calculates the optimal blade pitch angle and sends control signals to the pitch actuators. This ensures that the wind turbines operate at maximum efficiency under different wind conditions, maximizing power generation and reducing wear and tear on the turbines. In a power substation, the module can monitor and control the status of circuit breakers, transformers, and other electrical equipment. By collecting data from sensors attached to these devices, such as temperature sensors on transformers or status sensors on circuit breakers, it can detect any abnormal conditions early. If a transformer starts to overheat, the 3BHB004661R0101 can send an alert and initiate corrective actions, such as activating cooling fans or notifying maintenance personnel. This helps in preventing power outages and protecting expensive electrical equipment, ultimately enhancing the reliability of the power supply.

Compatible and Related Models

- 3BHB003295R0002 – An older model that the 3BHB004661R0101 may have replaced in some applications. It may have had similar basic functions but with less advanced features or lower performance capabilities compared to the 3BHB004661R0101.

- 3BHB002433R0001 – Another related model that could have been used in earlier industrial control setups. The 3BHB004661R0101 likely offers improvements in areas such as data processing speed, communication capabilities, or reliability compared to this model.

- 3BHB003688R0101 – This model may be a sub – board or a component that is related to the 3BHB004661R0101. In some cases, multiple 3BHB003688R0101 sub – boards may be included in a system where the 3BHB004661R0101 is the main module, working together to provide a more comprehensive functionality.

- KUC711AE101 – Often associated with the 3BHB004661R0101, it may be a software or firmware version that is specifically designed to work with this module. The combination of the 3BHB004661R0101 hardware and the KUC711AE101 software/firmware may offer enhanced features, such as advanced control algorithms or additional communication protocols.

- ACS 880 – A variable – speed drive from ABB. The 3BHB004661R0101 can be integrated with the ACS 880 in industrial applications. For example, the module can receive signals from sensors in a production line and then send control commands to the ACS 880 to adjust the speed of motors driving conveyor belts or other equipment, optimizing the overall production process.

Setup & Service Guidance

When installing the ABB 3BHB004661R0101, proper grounding is of utmost importance. Connect the grounding terminal of the module to a reliable earth ground. This helps to protect the module from electrical surges, which can be common in industrial environments due to the operation of large motors and other electrical equipment. Grounding also ensures the safety of the entire industrial control system, protecting operators from potential electrical hazards. Ensure that there is sufficient space around the module for proper ventilation. During operation, the module generates heat, and proper ventilation is necessary to dissipate this heat effectively. Install it in an area where there are no obstructions to air circulation, such as away from other heat – generating components or in an enclosure with adequate ventilation holes. If the module has a DIN – rail mounting option, firmly secure it to the rail. Use the appropriate mounting hardware to prevent vibrations from causing loose connections. Loose connections can lead to intermittent failures, where the module may not function properly or may drop communication with other devices in the system.

For long – term operation, regular inspections are recommended. Inspect the module at least once every three months. Check for any signs of physical damage, such as cracks in the casing, which could expose internal components to dust, moisture, or mechanical stress. Look for loose wires or connectors, as these can also cause connection problems. Monitor the operating temperature of the module. If it exceeds the specified temperature range, it could indicate a problem with the internal components or the cooling mechanism. You can use a temperature sensor or an infrared thermometer to measure the temperature. Regularly update the module’s firmware as ABB releases new versions. Firmware updates often include bug fixes, performance improvements, and compatibility enhancements. Keep the module clean from dust and debris. Dust can accumulate on the module over time, especially in industrial environments with poor air quality. Dust can act as an insulator, trapping heat and potentially causing overheating. Use a soft, dry brush or compressed air to clean the module gently.

Warranty & Support Coverage

ABB stands firmly behind the quality and reliability of the 3BHB004661R0101. The module typically comes with a comprehensive warranty, which reflects the manufacturer’s confidence in its durability. The warranty period may vary depending on the region and the specific terms of purchase, but it generally provides coverage for a significant period, during which ABB will repair or replace the module if it fails due to manufacturing defects.

For more information, please click below to learn more:

Be the first to review “ABB 3BHB004661R0101 power drive module board” Cancel reply

Reviews

There are no reviews yet.