Description

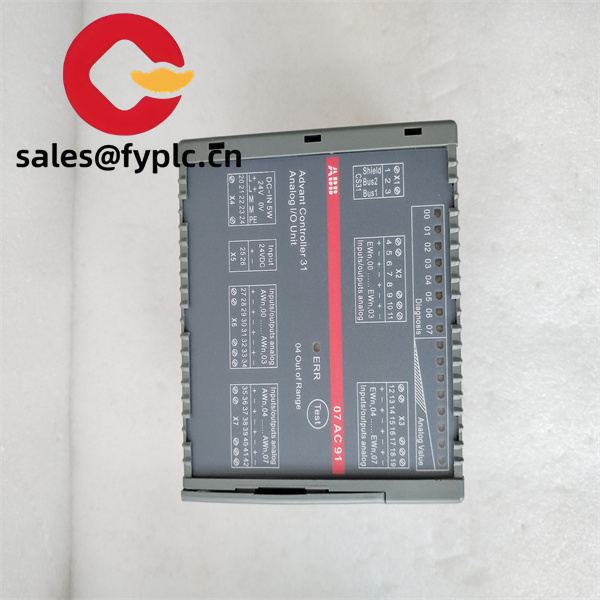

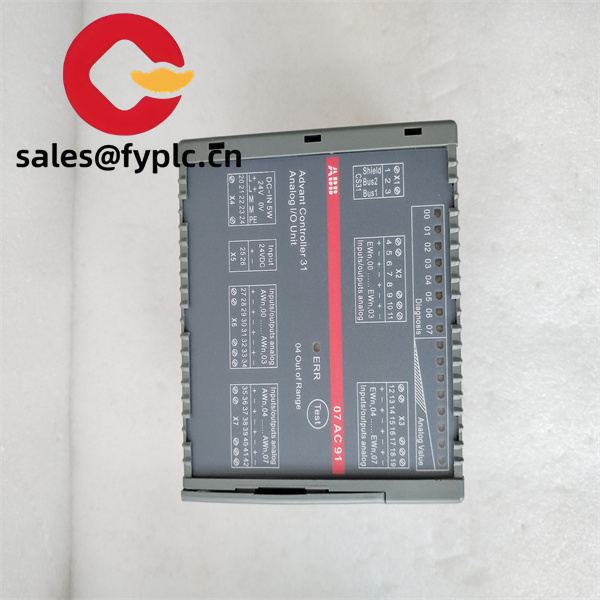

ABB 07AC91F Input/Output Controller

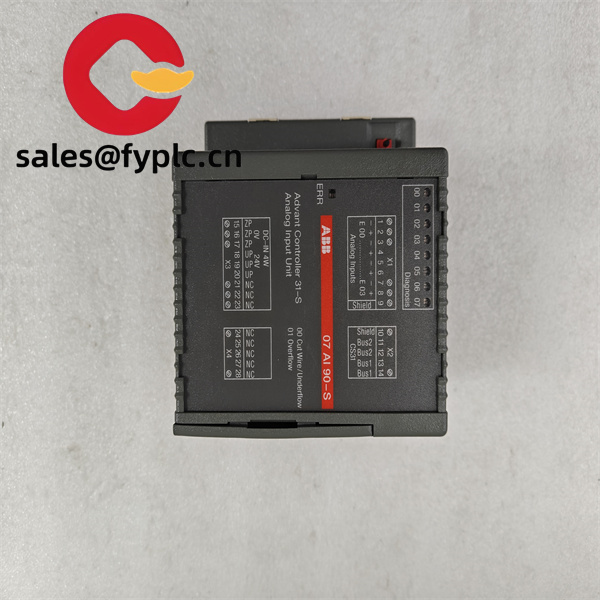

In the dynamic world of industrial automation, having a reliable and efficient analog input/output (I/O) module is crucial. ABB, a renowned global leader in power and automation technologies, presents the 07AC91F module, designed to meet the diverse and demanding requirements of modern industrial control systems.

The ABB 07AC91F is an analog I/O module that plays a pivotal role in industrial automation setups. It is engineered to interface with various analog sensors and actuators, serving as a key component in systems that require precise monitoring and control of continuous, variable signals. This module is an integral part of broader industrial control architectures, whether it’s a Distributed Control System (DCS) or a Supervisory Control and Data Acquisition (SCADA) system. Its primary purpose is to enable seamless communication between analog field devices and digital control systems, ensuring accurate data transfer and control signal distribution.

Technical Highlights Table

Functional Strengths & Design Advantages

This unit has been engineered to offer exceptional performance in industrial environments. The 07AC91F module showcases high – speed data conversion capabilities, ensuring that real – time monitoring and control are achieved without significant delays. Its resilience is a standout feature, with the ability to withstand harsh industrial conditions, including electrical noise and voltage fluctuations.

In terms of interoperability, the 07AC91F is designed to work harmoniously with a wide range of other components within an industrial control system. It has been carefully crafted to be compatible with different sensors and actuators, making it easier for engineers to integrate into existing setups or design new, comprehensive control systems. The build quality of the 07AC91F is top – notch. Using high – quality materials and advanced manufacturing techniques, ABB has ensured that this module can endure the rigors of continuous industrial use, contributing to its long – term reliability.

Industrial Use Cases & Value Scenarios

The ABB 07AC91F module finds its place in a multitude of industrial environments. In the manufacturing industry, it is often deployed in production lines for process reliability. For instance, in a food and beverage factory, the module can be used to monitor and control parameters such as temperature, pressure, and liquid flow. By accurately converting analog signals from sensors to digital data for the control system, it helps maintain product quality and consistency.

In the energy sector, especially in power generation plants, the 07AC91F plays a vital role in ensuring smooth operations. It can be used in monitoring the voltage and current levels of power distribution systems, as well as controlling the operation of various electrical equipment. In a DCS setup within a power plant, the module’s ability to handle analog signals precisely contributes to the overall stability and efficiency of the power generation process.

Compatible and Related Models

- 07AC91D – A related module with specific enhancements for certain industrial applications, perhaps with different signal handling capabilities.

- GJR5252300R3101 – A model closely associated with the 07AC91F, sharing some common design elements and being part of the same product family within ABB.

- 07AC91 (base model) – The base version of the module, on which the 07AC91F may have additional features or optimizations.

- ABB AC31 – related modules – Such as those that work in tandem with the 07AC91F within the AC31 control system framework, providing complementary functions like additional input/output channels or different communication interfaces.

- ABB analog I/O modules with different channel configurations – For example, modules with more or fewer analog input and output channels, which can be chosen based on the complexity and scale of the industrial control project.

Setup & Service Guidance

When installing the 07AC91F module, several precautions should be taken. If mounting on a DIN rail, ensure that the rail is properly secured and free from any debris. For screw – based installations, use the appropriate screws and torque settings as recommended by ABB. Grounding is crucial to protect the module from electrical surges. Make sure to connect the grounding wire correctly according to the installation manual. Also, consider the airflow around the module. Adequate ventilation should be provided to prevent overheating, especially in environments with high ambient temperatures.

For long – term operation, regular inspections are necessary. Check for any signs of physical damage, such as cracks or loose connections, during routine maintenance. Monitor the module’s performance by periodically checking the accuracy of the analog signals it processes. If there are any discrepancies in the data readings, it could indicate a problem with the module or the connected sensors. It is also advisable to keep the module’s software or firmware updated to benefit from the latest performance improvements and bug fixes.

Warranty & Support Coverage

ABB has full confidence in the durability of the 07AC91F module. Backed by a comprehensive warranty, customers can be assured of the product’s quality. In case of any issues, ABB offers global support, ensuring that help is readily available, no matter where the module is installed. Technical documentation, including installation guides, user manuals, and troubleshooting guides, is easily accessible, enabling users to resolve common problems independently. Additionally, remote support services are available, allowing ABB’s experts to diagnose and potentially fix issues without the need for an on – site visit. This commitment to long – term reliability and customer assurance makes the 07AC91F a trustworthy choice for industrial automation applications.

For more information, please click below to learn more:

Reviews

There are no reviews yet.