Description

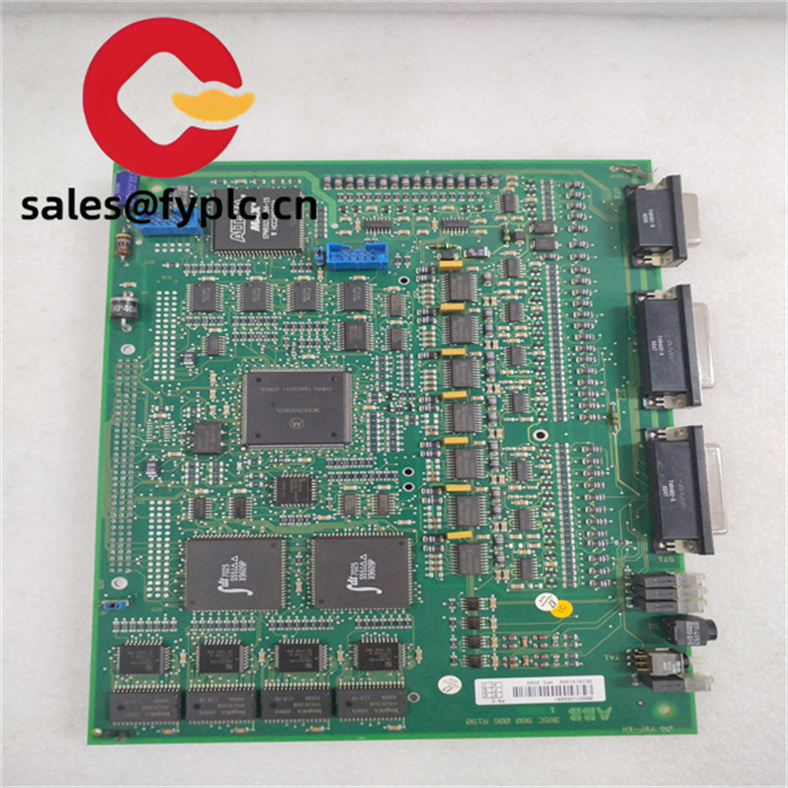

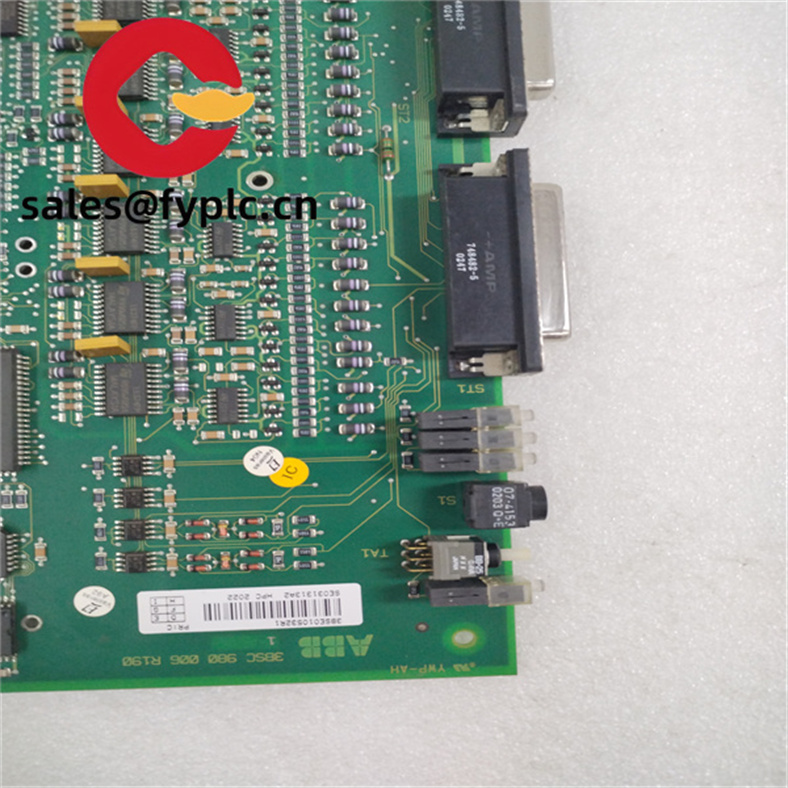

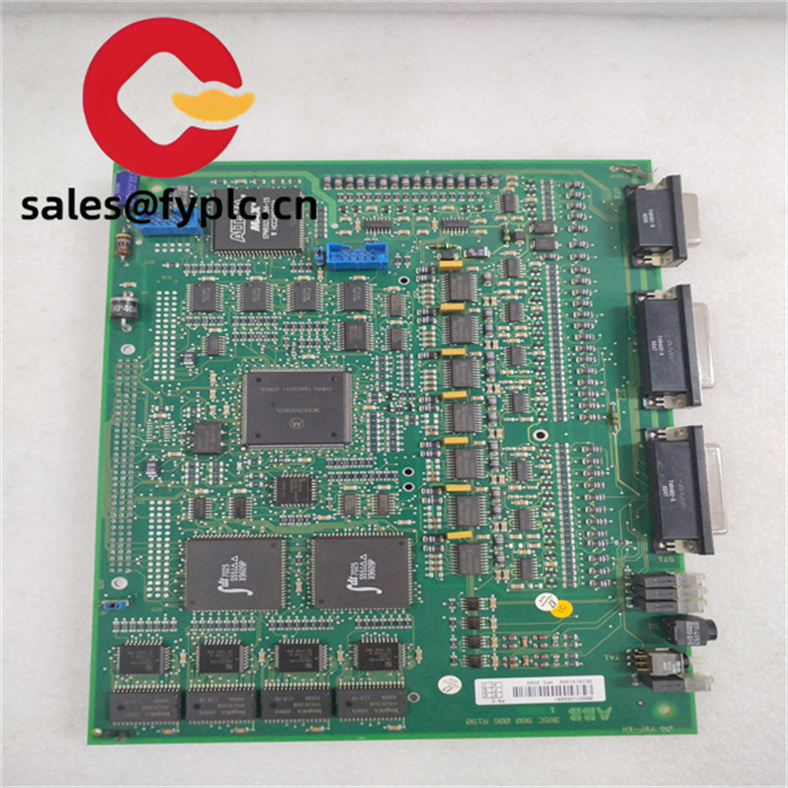

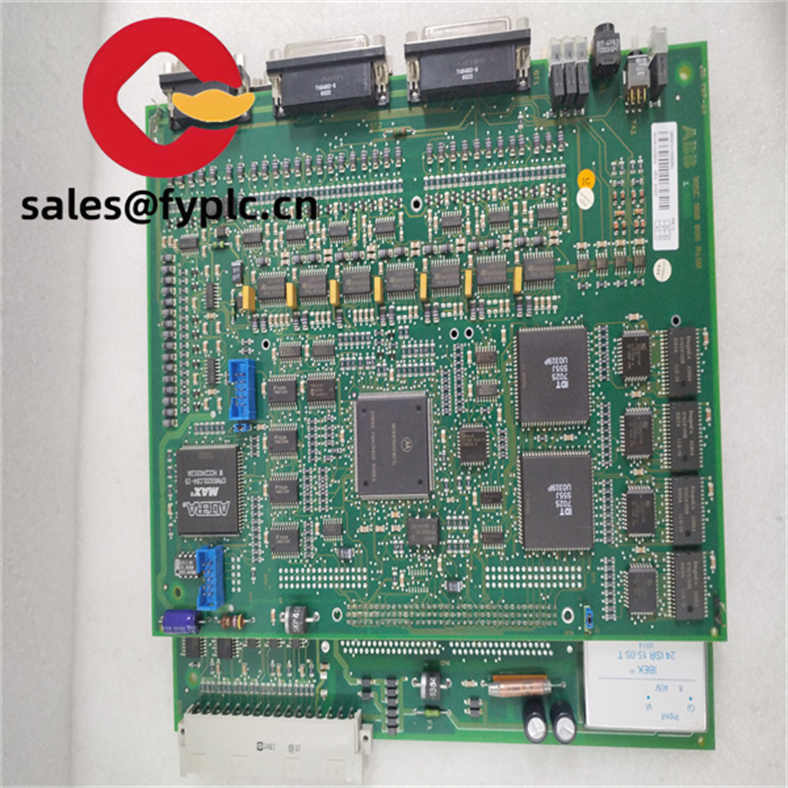

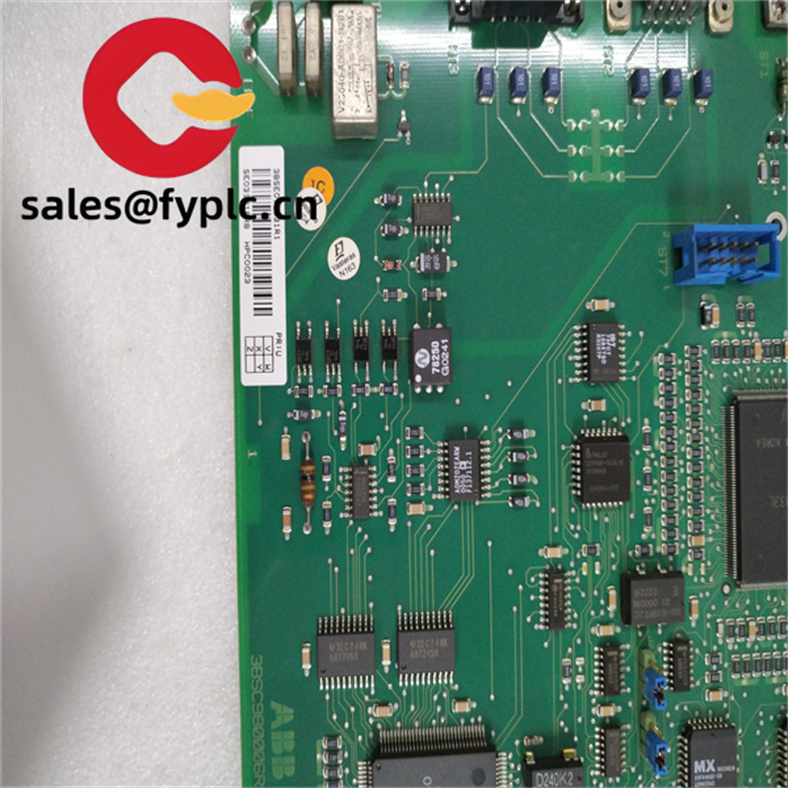

ABB PM665 processor controller module

In the dynamic landscape of industrial automation, the PM665 by ABB emerges as a highly versatile and powerful programmable automation controller. Engineered to meet the complex demands of modern industrial control systems, this controller serves as the nerve center for a wide array of applications, enabling seamless integration, precise control, and efficient data processing across diverse industrial environments.

The PM665 is specifically designed to be the backbone of industrial automation setups. Whether it’s integrated into large-scale manufacturing plants, power generation facilities, or process industries, this controller plays a crucial role in ensuring smooth operations. Its primary purpose is to receive inputs from various sensors monitoring critical parameters such as temperature, pressure, flow rate, and position. By processing these signals with remarkable speed and accuracy, the PM665 generates appropriate control signals to actuators, motors, and other equipment, thus maintaining optimal process conditions and enhancing overall productivity. In essence, it bridges the gap between field devices and higher-level control systems, making it an indispensable component for achieving automation excellence.

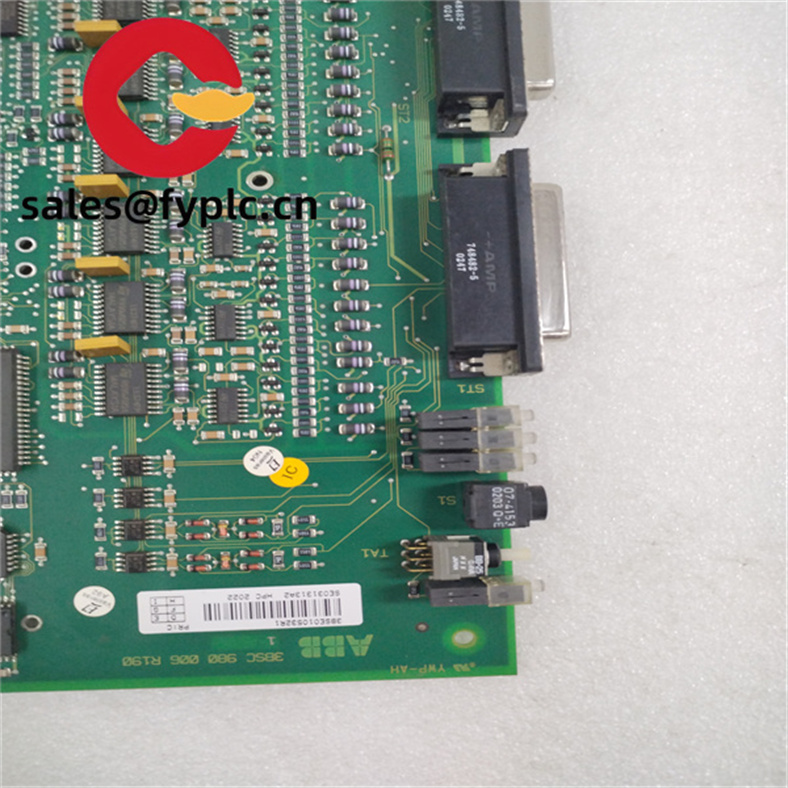

| Label |

Specification |

| Model Number |

PM665 |

| Brand |

ABB |

| Type |

Programmable Automation Controller |

| Input Voltage |

24V DC |

| Operating Temp |

-20°C – 60°C |

| Communication Method |

Ethernet, Profibus DP, Modbus RTU |

| Mounting |

DIN-rail mountable |

| Weight |

Approximately 1.2 kg |

| Certifications |

CE, UL, IEC 61131 – 2 |

| Dimensions |

150mm x 100mm x 60mm (H x W x D) |

The PM665 boasts an impressive range of functional strengths and design advantages that set it apart in real-world industrial applications. One of its key highlights is its exceptional processing power. Equipped with a high-performance processor, it can handle complex control algorithms and large volumes of data in real-time. In a fast-paced automotive manufacturing line, for example, the PM665 can rapidly analyze data from multiple sensors and make split-second decisions to adjust the operation of robotic arms, conveyor belts, and other equipment, ensuring seamless production flow and minimizing downtime.

Reliability is at the core of the PM665‘s design. Built with robust components and a rugged enclosure, it can withstand the harsh conditions typical of industrial settings, including electrical noise, vibrations, and temperature fluctuations. Its advanced self-diagnostic capabilities continuously monitor the controller’s internal functions, enabling early detection of potential issues and reducing the risk of unexpected failures. This reliability translates into reduced maintenance requirements and increased system uptime, saving both time and costs for industrial operators.

Interoperability is another significant strength of the PM665. It supports multiple industrial communication protocols, allowing it to integrate seamlessly with a wide variety of devices and systems, regardless of the manufacturer. This flexibility enables easy expansion and upgrading of existing automation setups. Whether it’s connecting to new sensors, actuators, or higher-level management systems, the PM665 can adapt effortlessly, making it a future-proof solution for evolving industrial needs.

For more information, please click below to learn more:

Reviews

There are no reviews yet.