Description

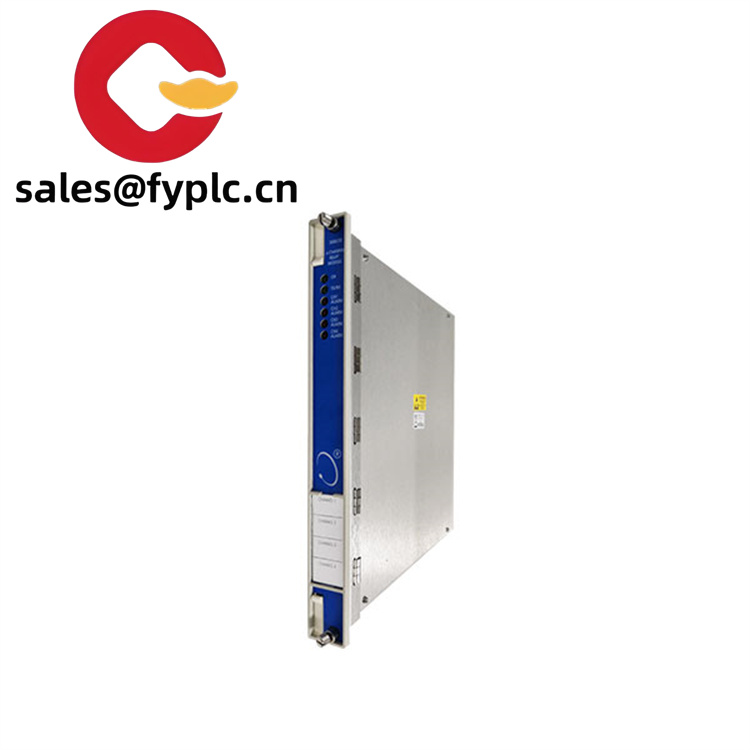

Bently 3500-22M Transient Data Interface Control Front Card Module

In the complex ecosystem of industrial automation, effective data management and communication are the linchpins of seamless operations. The Bently 3500-22M Communication Gateway Module emerges as a game-changer, engineered by Bently, a stalwart in the industrial hardware domain. This module is not just another component; it’s a crucial bridge that enables diverse industrial devices to ‘talk’ to each other, facilitating the smooth flow of data across various automation systems. Whether it’s a Supervisory Control and Data Acquisition (SCADA) setup overseeing a vast oil pipeline network or a Distributed Control System (DCS) managing a complex chemical plant, the Bently 3500-22M plays a pivotal role in ensuring that information is transmitted accurately and in real-time. It acts as the communication nerve center, integrating different subsystems into a cohesive whole, thereby enhancing the overall efficiency and reliability of industrial control systems.

| Label | Specification |

|---|---|

| Model Number | 3500-22M |

| Brand | Bently |

| Type | Communication Gateway Module |

| Input Voltage | 20 – 30 Vdc |

| Operating Temp | -30°C to +65°C (-22°F to +150°F) |

| Communication Method | Ethernet, Serial (RS-232/RS-485) |

| Mounting | Designed for installation in the 3500 rack |

| Weight | [Varies, consult datasheet] |

| Certifications | Meets international standards for electromagnetic compatibility and safety |

| Dimensions | [Specific dimensions based on model variant] |

| IP Rating | [Depends on enclosure, typically suitable for industrial environments] |

| Protocols Supported | Modbus TCP, Profibus DP, Ethernet/IP, OPC UA |

Click below to learn more:

ABB UFC760BE141 Control Board Driver Board Controller

ABB XC32L1-A2.0 indirect excitation system functional module

ABB UNITOLO1020 3BHE036163R61 excitation controller

ABB UFC921A101 3BHE024855R01 Control Converter Module

ABB LDSYN-101 3BHE005555R01 Power Control

ABB PCD232A Drive System Controller Input/Output Analog Module

Reviews

There are no reviews yet.