Description

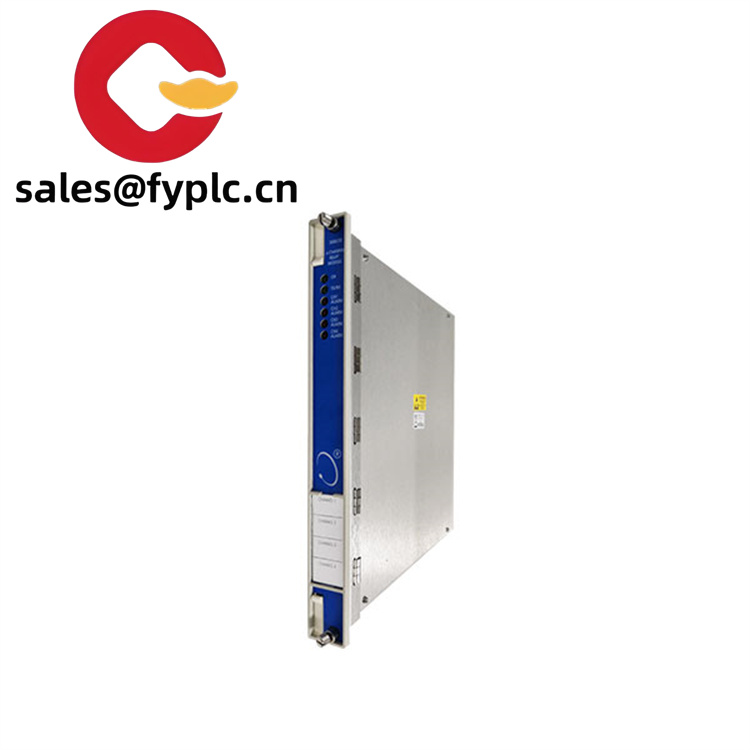

Bently 3500-32/3500-33 large card relay module

This module serves as a linchpin in applications where precise control and reliable switching are non – negotiable within industrial automation systems. Be it in a large – scale power generation plant, a complex chemical manufacturing facility, or a high – speed manufacturing line, the Bently 3500 – 32 integrates seamlessly into the broader industrial control ecosystem. It acts as a crucial bridge, enabling effective control and rapid response to diverse operational conditions. By relaying signals based on input from various sensors and monitoring modules, it ensures that industrial processes run smoothly and safely.

| Label | Specification |

|---|---|

| Model Number | 3500 – 32 |

| Brand | Bently |

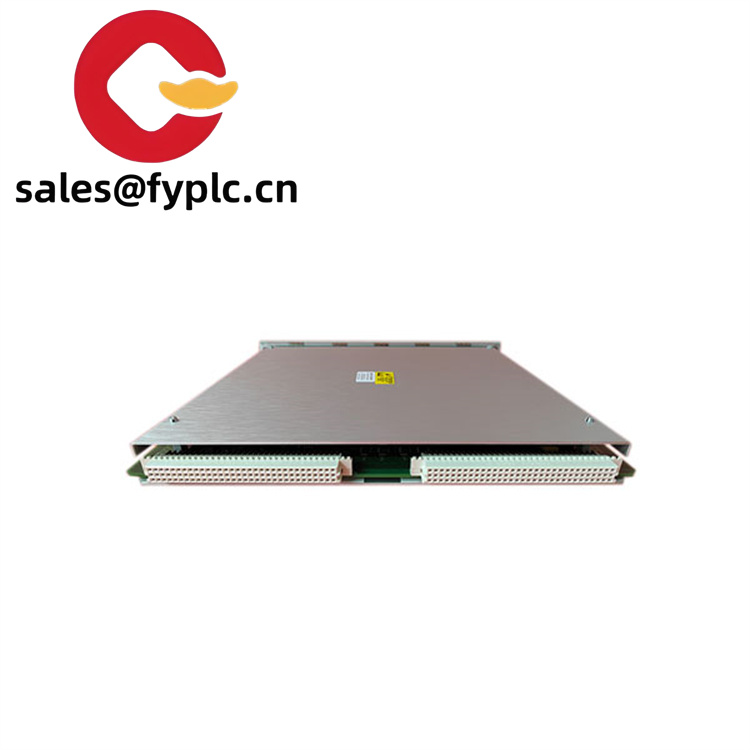

| Type | 4 – Channel Relay Module |

| Input Voltage | Options may include 24 Vdc, 120 Vac, 220 Vac; check product details for the exact range |

| Operating Temp | – 40 °C to + 85 °C |

| Communication Method | Interfaces with other 3500 system modules via internal bus communication; some versions might support external protocols like Modbus for broader system integration |

| Mounting | Installed in the 3500 series racks, usually adjacent to relevant modules |

| Weight | [Specify weight value if available, e.g., 1.5 kg] |

| Certifications | Complies with international standards for industrial use, covering electrical safety and electromagnetic compatibility |

| Dimensions | [Provide dimensions in mm, e.g., 100 mm x 150 mm x 50 mm] |

| IP Rating | May have an IP rating such as IP20 for protection against dust and limited solid object ingress in typical industrial environments |

| Protocols Supported | [If applicable, list specific protocols, e.g., in certain configurations, it could support basic digital communication protocols for relay control] |

| Output Current Capacity per Channel | [Specify value, e.g., 5 A] |

| Relay Type | Could be solid – state or electromechanical, tailored for industrial applications |

For more information, please click on the following link:

AB 2711 series 2711-K6C15 touch screen accessories

Rockwell 1762-OW16 Safety Output Module Relay

Triconex 3009 Enhanced Main Processor (UMP) Module

Triconex 3101/Triconex3201 Triple Modular Redundant Main Processor

AB 2711-K6C5 touch screen human-machine interface function module

Allen Bradley 1769-L32C | Processor Analog Input/Output Module

ABB UFC718AE01-HIEE300936R0001 Power Control Equipment Module

Reviews

There are no reviews yet.