Description

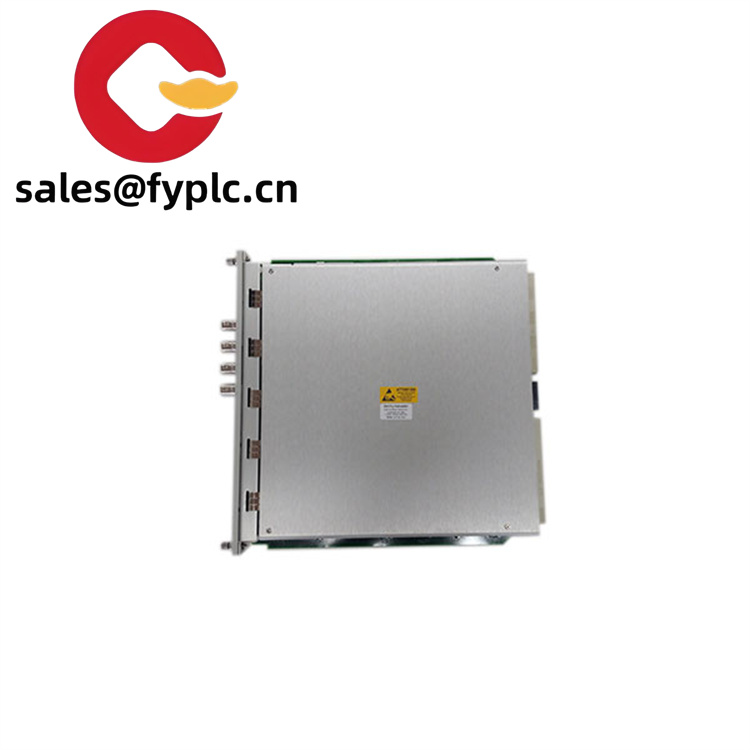

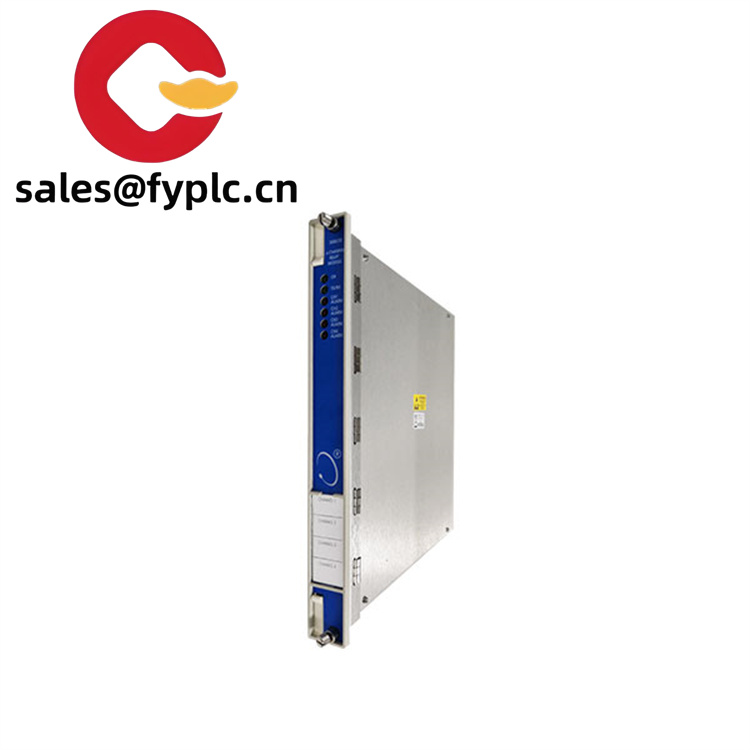

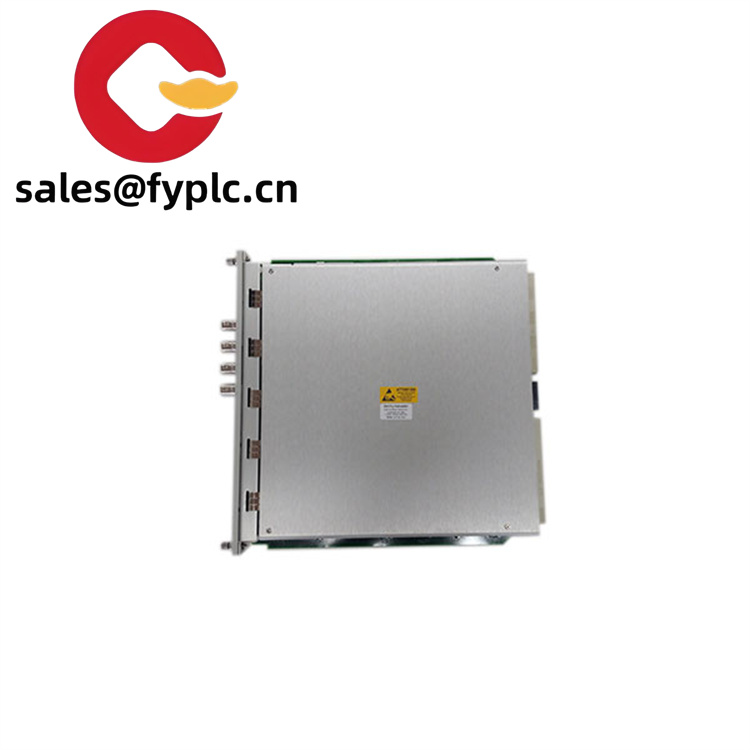

Bently3500-42M Vibration Monitor Acceleration Module

3500-42M

This module is specifically engineered for industrial automation and machinery health monitoring systems. It plays a crucial role in various industrial setups, from large – scale power plants where turbines and generators need constant surveillance to the complex manufacturing lines in the automotive or electronics industries. By integrating with a wide range of sensors, the Bently 3500 – 42M acts as a central hub for collecting, processing, and analyzing data related to machinery vibrations and seismic – like activities, ensuring the smooth operation of industrial processes.

| Label |

Specification |

| Model Number |

3500 – 42M |

| Brand |

Bently |

| Type |

Proximitor Seismic Monitor I/O Module |

| Input Voltage |

12 Vdc, with a current draw of 50 mA |

| Operating Temp |

– 40 °C to + 85 °C |

| Communication Method |

Communicates with other components within the 3500 system through the internal communication bus; can also interface with external control systems via compatible protocols (details may vary by configuration) |

| Mounting |

Installed within the 3500 series racks, designed for easy integration with other modules |

| Weight |

[Weight value if available, e.g., 1.2 kg] |

| Certifications |

Complies with international standards for industrial use, covering aspects such as electrical safety and electromagnetic compatibility |

| Dimensions |

178 mm x 178 mm x 110 mm |

| IP Rating |

[Specify IP rating, e.g., IP20 for protection against dust and limited ingress of solid objects in typical industrial environments] |

| Protocols Supported |

[List relevant communication protocols if applicable, e.g., Modbus in some versions for data exchange with external devices] |

| Operating Range |

0.1 Hz to 1 kHz |

| Power Consumption |

7.7 watts |

| Resolution |

0.3662 A per bit |

3500-42M

The Bently 3500 – 42M exhibits several functional strengths and design advantages that set it apart in real – world industrial scenarios. Its high – precision sensors and advanced signal – conditioning algorithms enable it to detect even the slightest vibrations or changes in machinery movement. This level of accuracy is crucial for early – stage fault detection, allowing maintenance teams to address potential issues before they escalate into major breakdowns. The module’s robust construction ensures its resilience in harsh industrial environments, whether it’s the high – temperature, high – humidity conditions of a chemical plant or the dusty and vibrating surroundings of a mining operation.

Operators benefit from its excellent interoperability. It can seamlessly interface with a variety of proximity and seismic transducers, as well as other modules within the Bently 3500 series. This compatibility makes it easy to integrate into existing industrial control systems without the need for extensive re – engineering. Each of the four channels can be programmed independently using the 3500 rack configuration software, providing the flexibility to perform different monitoring functions simultaneously, such as radial vibration monitoring on one pair of channels and thrust position monitoring on another.

The Bently 3500 – 42M finds extensive application across multiple industries. In the power generation industry, it is deployed to monitor the vibrations of turbines and generators. By continuously measuring parameters like acceleration, velocity, and displacement, it can quickly detect any abnormal behavior, such as unbalanced rotors or misaligned shafts. In the event of a deviation from normal operating conditions, the module can trigger alarms and relay critical information to the plant’s control system, enabling operators to take immediate corrective action. This helps prevent costly downtime and extends the lifespan of expensive power – generation equipment.

In the manufacturing sector, especially in industries that rely on high – speed rotating machinery like automotive manufacturing, the Bently 3500 – 42M plays a vital role in ensuring product quality and production efficiency. It can monitor the vibration of motors, spindles, and robotic arms, ensuring that they operate within the specified tolerances. If a machine’s vibration exceeds the set limits, it could lead to poor – quality products or equipment failures. The Bently 3500 – 42M allows manufacturers to proactively maintain their machinery, reducing production disruptions and improving overall productivity.

Several models are closely related to the Bently 3500 – 42M. The Bently 3500 – 15 power module is essential as it supplies the necessary power for the Bently 3500 – 42M to function correctly. Without stable power from the 3500 – 15, the operation of the 3500 – 42M could be severely affected. The Bently 3500 – 32 relay module often works in tandem with the Bently 3500 – 42M. When the 3500 – 42M detects abnormal vibration levels, it can send signals to the 3500 – 32, which can then trigger appropriate actions, such as shutting down equipment or activating auxiliary cooling systems. The Bently 3500 – 53 displacement monitoring module can share data with the Bently 3500 – 42M, providing a more comprehensive view of machinery health. The Bently 3500 – 60 system monitor module can integrate the data from the 3500 – 42M to give an overall status of the entire industrial system. The Bently 3500 – 72 speed/torque monitor module’s data can also be used in conjunction with the 3500 – 42M’s vibration data to analyze the performance of rotating machinery more accurately.

When installing the Bently 3500 – 42M, it’s important to follow the proper procedures. Mount it securely in the designated slot within the 3500 series rack, ensuring a stable connection. When connecting sensors and other external devices, pay attention to the correct wiring and signal – type compatibility. Grounding the module properly is crucial to protect against electrical interference and ensure accurate measurements.

For more information, please click on the following link:

Reviews

There are no reviews yet.