Description

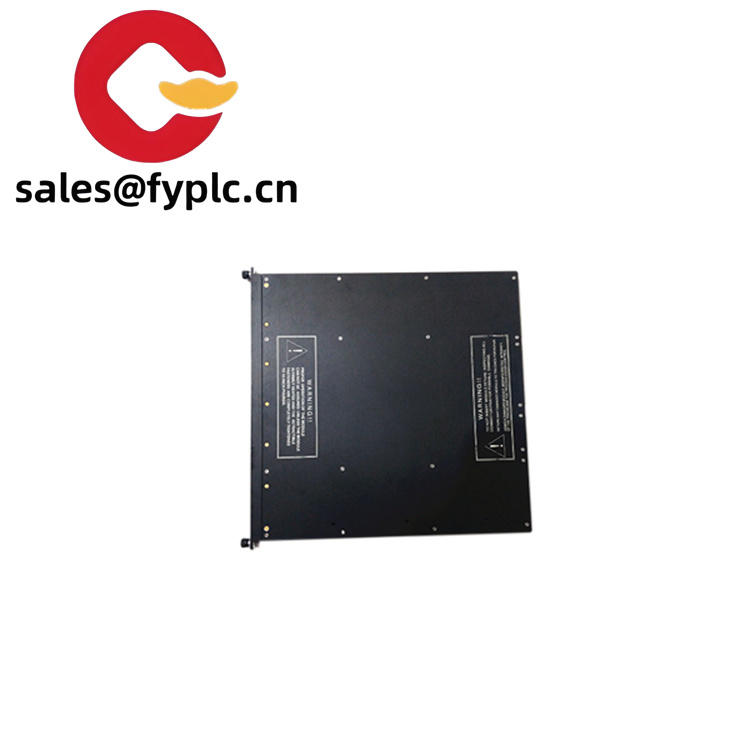

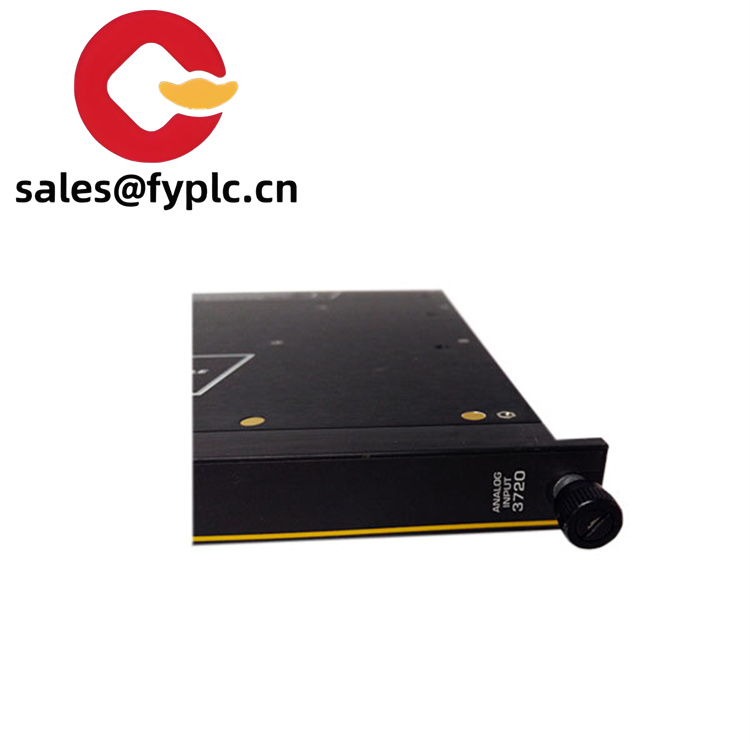

Triconex 3720 Digital Input/Output Controller Module

Triconex 3720

The Triconex 3720 is a high-reliability analog output module designed for safety-critical industrial control systems, particularly within Triconex’s Safety Instrumented System (SIS). Engineered to deliver precise and fault-tolerant analog signals to field devices (e.g., valves, actuators), it ensures safe and stable operation in industries such as oil & gas, chemical processing, and power generation.

| Label |

Specification |

| Model Number |

3720 |

| Brand |

Triconex |

| Type |

Analog Output Module |

| Output Channels |

16 channels (configurable for voltage/current outputs) |

| Output Range |

– Voltage: 0–5 VDC, ±5 VDC, 1–5 VDC

– Current: 4–20 mA, 0–20 mA |

| Resolution |

16 bits (high-precision signal generation) |

| Accuracy |

±0.1% of full-scale (depends on output range) |

| Redundancy |

Triple Modular Redundancy (TMR) with self-diagnostic capabilities |

| Isolation |

Galvanic isolation (typically 500 VDC) between channels and backplane |

| Power Supply |

24 VDC (nominal, with surge protection) |

| Operating Temperature |

-20°C to +70°C |

| Communication |

Integrates with Triconex backplane via high-speed serial bus |

| Certifications |

Compliant with IEC 61508 (SIL 3), IEEE, and EMC/EMI standards |

Triconex 3720

-

Triple Modular Redundancy (TMR)

The module uses three independent signal paths to detect and mitigate faults. If one channel fails, the other two continue to provide accurate outputs, ensuring uninterrupted control in critical scenarios (e.g., emergency shutdowns).

-

High Precision and Stability

- 16-bit resolution ensures precise conversion of digital commands to analog signals, enabling fine-grained control of actuators (e.g., regulating valve positions or motor speeds).

- Built-in calibration and linearization features maintain signal accuracy over time and across temperature ranges.

-

Fault Tolerance and Diagnostics

- Continuous self-testing detects faults like open circuits, short circuits, or signal drift.

- Faults are flagged to the control system, allowing for proactive maintenance (e.g., replacing a faulty channel without system downtime).

- “Fail-safe” outputs can be configured to default to a safe state (e.g., 0 mA, 20 mA, or mid-scale) in the event of a module failure.

-

Flexible Configuration

- Supports multiple output types (voltage/current) and ranges, adaptable to diverse field devices.

- Configurable via Triconex software (e.g., Tricon Expert) for scaling, alarming, and diagnostic thresholds.

-

Industrial-Grade Durability

- Withstands harsh environments (vibration, humidity, electromagnetic interference).

- Hot-swappable design allows replacement without powering down the system, minimizing downtime.

-

Triconex 3720

- Process Control: Sending analog signals to control valves for regulating flow, pressure, or temperature in chemical reactors or pipelines.

- Emergency Shutdown Systems (ESD): Driving actuators to close valves or shut down equipment in hazardous situations (e.g., leaks, overpressure).

- Power Generation: Controlling steam turbines, boiler feedwater pumps, or generator excitation systems.

- Marine and Offshore: Managing critical systems on oil rigs or ships, where safety and reliability are non-negotiable.

- Installation: Mounted on a Triconex backplane within a rack-mounted control cabinet, with field wiring connected via terminal blocks.

- Communication: Seamlessly interfaces with Triconex controllers (e.g., Tricon series) to receive digital commands and transmit status data.

- Maintenance:

- Regular checks include verifying output accuracy against calibrated devices.

- Firmware updates ensure compatibility with system upgrades.

- Inspect for physical wear (e.g., loose connections, corrosion) in harsh environments.

-

For more information, please click on the following link:

Reviews

There are no reviews yet.