Description

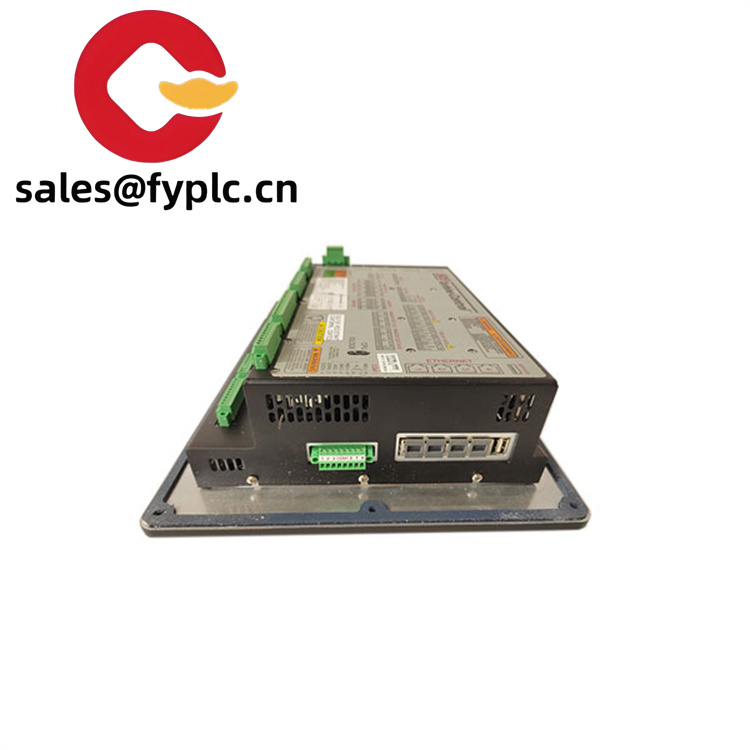

Woodward 8200-1300/8200-1302 DCS Industrial Control Digital Governor

8200 – 1300

The primary function of the Woodward 8200 – 1300 is to regulate the operation of single or dual (split range) actuator steam turbines. It can be integrated into a plant’s distributed control system (DCS), enabling centralized monitoring and control across the entire industrial process. Alternatively, it can function as a stand – alone unit, offering flexibility for smaller – scale applications or as a backup control solution. This adaptability makes it an ideal choice for both new installations and retrofitting existing systems.

| Label |

Specification |

| Model Number |

8200 – 1300 |

| Brand |

Woodward |

| Type |

Digital Governor for Steam Turbines |

| Power Supply |

18 – 32 VDC (low – voltage DC for stable operation) |

| Controller Configuration |

Five PID controllers (Speed/Load PID, Cascade PID, Aux 1 PID, Aux 2 PID) for versatile control strategies |

| Communication Interfaces |

Ethernet (for connection to factory DCS, service tools, and RemoteView operator panels), CANOpen (for actuator connection, e.g., to Woodward variable – stroke actuators and DSLC – II power management networks) |

| HMI Features |

Integrated graphical front – panel HMI with multi – language support (including Chinese) for easy operator interaction; large screen for simple navigation and icon – based views of parameters and performance |

| Operating Temperature Range |

Can operate within a wide temperature range, suitable for industrial environments (specific range details not fully provided in sources but expected to be industrial – grade, e.g., – 20°C to 60°C) |

| Control Capabilities |

Next – generation advanced load rejection performance; 3 critical speed avoidance bands; reverse rotation sensing and alarm; OptiTune adaptive PID technology for optimal turbine performance tuning; acceleration PID to limit overshoot during start – up |

| Monitoring Features |

High – speed data logging for monitoring turbine operation and stress, including run – time and first – trip information; vibration monitoring (with sensor kit 8928 – 7482) for protection and control |

| Physical Dimensions |

[No dimension data in given sources; designed to fit standard control panel spaces in industrial settings] |

| Certifications |

[No specific certification details in given sources but expected to meet relevant industrial standards for safety and performance] |

8200-1300

The 8200 – 1300’s suite of five PID controllers is a key differentiator. The speed/load PID controller ensures that the turbine maintains a stable rotational speed under varying load conditions, crucial for consistent power generation. The cascade PID controller can be used to regulate complex processes, such as controlling steam pressure in relation to turbine speed. The aux 1 and aux 2 PID controllers offer additional flexibility, allowing for the integration of other control variables, such as temperature or flow rate, depending on the specific application requirements.

The device’s communication capabilities are equally impressive. With Ethernet connectivity, it can easily interface with modern DCS systems, enabling real – time data exchange between the turbine and the plant’s central control room. This seamless integration allows operators to monitor and adjust turbine parameters remotely, enhancing operational efficiency. The CANOpen actuator connection simplifies the connection to Woodward’s own variable – stroke actuators and power management networks, ensuring smooth and coordinated control of the turbine’s mechanical components.

8200-1300

- Woodward 8200 – 1301: A related digital governor in the 505 turbine control series. It is primarily used for AC/DC (88 – 264 V AC or 90 – 150 V DC) ordinary location compliance power. While the 8200 – 1300 has its own specific power supply requirements (18 – 32 VDC), the 8200 – 1301 offers an alternative for applications with different power input needs within the same general product family.

- Woodward 505XT: Another turbine control device. The 505XT is designed specifically for controlling certain types of turbines, such as extraction steam turbines, which have more complex control requirements compared to standard steam turbines. In contrast, the 8200 – 1300 is more versatile in its application to single or dual actuator steam turbines, but both devices are part of Woodward’s comprehensive turbine control solutions.

- Sensor Kit 8928 – 7482: This sensor kit is compatible with the 8200 – 1300 and is used for vibration monitoring. By integrating this kit, the 8200 – 1300 can enhance its protective and control functions, making it more suitable for industrial environments where equipment vibration can cause significant operational issues.

- RemoteView (8928 – 5311): A software or device that works in tandem with the 8200 – 1300. It enables virtual monitoring of the turbine’s operation from remote workstations or mobile devices. This is especially useful for operators who need to keep an eye on the turbine’s performance while away from the control room, allowing for timely intervention in case of any anomalies.

For more information, please click on the following link:

Reviews

There are no reviews yet.