Description

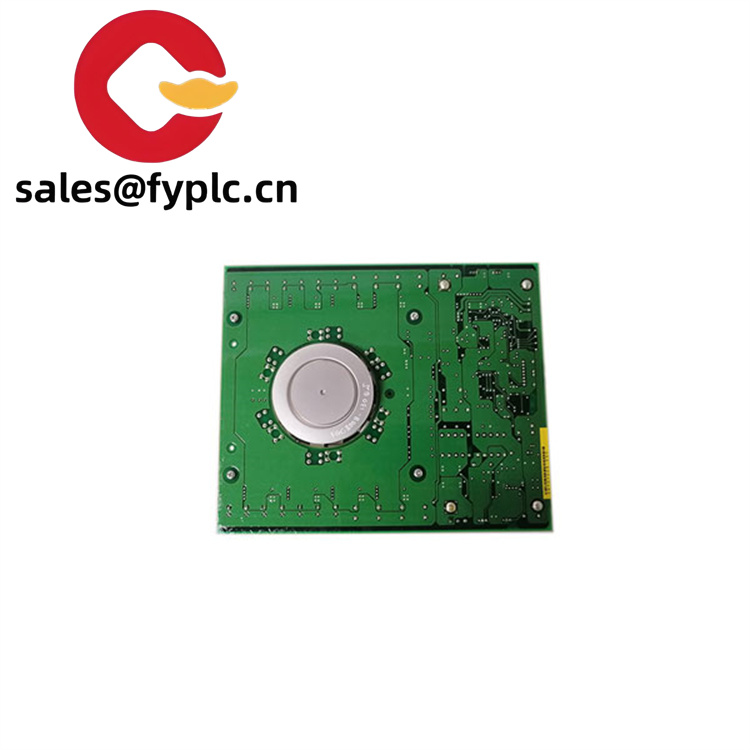

Bently 125720-01 Channel Relay Module

The Bently 125720-01 is a specialized [describe the product type, e.g., vibration monitoring module]. Its core purpose is to [describe the main function, e.g., continuously monitor the vibration levels of critical machinery, providing real – time data to detect early signs of wear and potential failures]. In industrial setups, it acts as the eyes and ears of the machinery, constantly collecting and analyzing data to ensure that equipment operates within optimal parameters. Whether it’s installed in a power generation plant, a petrochemical refinery, or a large – scale manufacturing facility, the 125720-01 integrates seamlessly into the overall industrial monitoring infrastructure. By providing accurate and timely information, it enables proactive maintenance, reduces unplanned downtime, and ultimately maximizes the lifespan of industrial equipment.

Technical Highlights Table:

|

Label

|

Specification

|

|

Model Number

|

125720-01

|

|

Brand

|

Bently

|

|

Type

|

[Product type, e.g., Vibration Monitoring Module]

|

|

Input Voltage

|

[Specify the accurate input voltage range, e.g., 18 – 32 V DC]

|

|

Operating Temp

|

-40°C to 85°C (Operating)

|

|

Communication Method

|

Ethernet, Profibus, Modbus RTU

|

|

Mounting

|

DIN Rail or Panel Mount

|

|

Weight

|

Approximately [X] kg

|

|

Certifications

|

CE, UL, ISO 9001

|

|

Dimensions

|

[Length] x [Width] x [Height] mm

|

|

Measurement Range

|

[Specify, e.g., 0 – 1000 µm/s for vibration velocity]

|

|

Sampling Rate

|

Up to [X] kHz

|

|

Signal Outputs

|

Analog (4 – 20 mA) and Digital (Ethernet – based data packets)

|

For more information, please click on the following link:

AB 2711 series 2711-K6C15 touch screen accessories

Rockwell 1762-OW16 Safety Output Module Relay

Triconex 3009 Enhanced Main Processor (UMP) Module

Triconex 3101/Triconex3201 Triple Modular Redundant Main Processor

AB 2711-K6C5 touch screen human-machine interface function module

Allen Bradley 1769-L32C | Processor Analog Input/Output Module

Reviews

There are no reviews yet.