Description

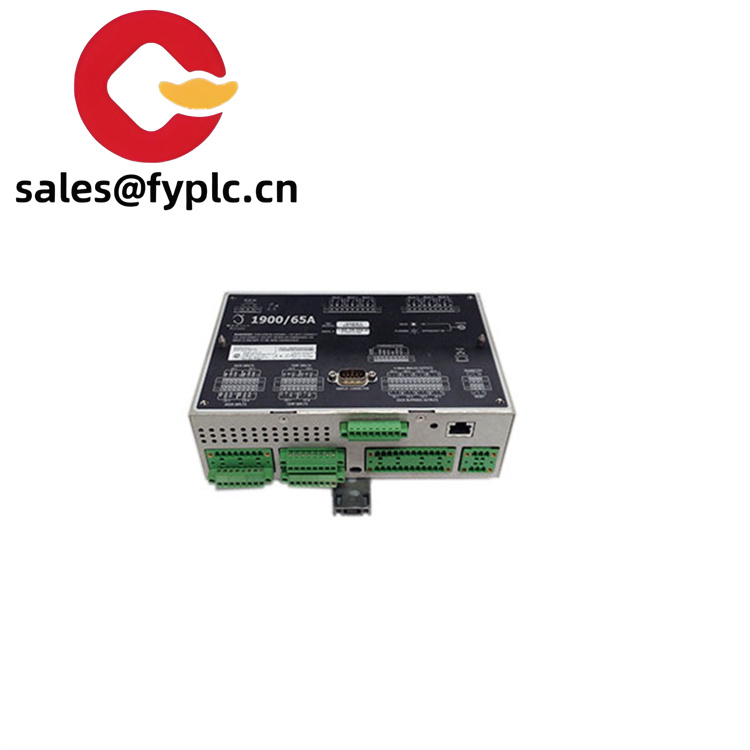

Bently 190065A vibration detector

The Bently 190065A serves a crucial role in industrial monitoring systems. [Describe its specific function, e.g., It is a specialized data acquisition module that precisely captures a wide range of parameters from industrial machinery, including vibration, temperature, and pressure. Acting as a key component, it interfaces with various sensors and relays the collected data to the central monitoring system in real – time, enabling operators to have a comprehensive and up – to – date understanding of the machinery’s health status.] Whether integrated into large – scale power generation plants, petrochemical refineries, or advanced manufacturing facilities, the 190065A fits seamlessly into the existing industrial infrastructure, providing valuable insights that are essential for proactive maintenance and optimized operations.

|

Label

|

Specification

|

|

Model Number

|

190065A

|

|

Brand

|

Bently

|

|

Type

|

[Product type, e.g., Data Acquisition Module]

|

|

Input Voltage

|

[Specify the accurate input voltage range, e.g., 18 – 32 V DC]

|

|

Operating Temp

|

-40°C to 85°C (Operating)

|

|

Communication Method

|

Ethernet, Profibus, Modbus TCP

|

|

Mounting

|

[Describe the mounting method, e.g., DIN Rail Mounting]

|

|

Weight

|

Approximately [X] kg

|

|

Certifications

|

CE, UL, ISO 9001

|

|

Dimensions

|

[Length] x [Width] x [Height] mm

|

|

Measurement Channels

|

[Specify the number, e.g., 8 channels]

|

|

Sampling Rate

|

Up to [X] kHz

|

|

Data Resolution

|

[Specify the resolution, e.g., 16 – bit]

|

|

Signal Input Types

|

[List the types, e.g., Analog (4 – 20 mA, 0 – 10 V), Digital (TTL)]

|

For more information, please click on the following link:

AB 2711 series 2711-K6C15 touch screen accessories

Rockwell 1762-OW16 Safety Output Module Relay

Triconex 3009 Enhanced Main Processor (UMP) Module

Triconex 3101/Triconex3201 Triple Modular Redundant Main Processor

AB 2711-K6C5 touch screen human-machine interface function module

Allen Bradley 1769-L32C | Processor Analog Input/Output Module

ABB UFC718AE01-HIEE300936R0001 Power Control Equipment Module

Reviews

There are no reviews yet.