Description

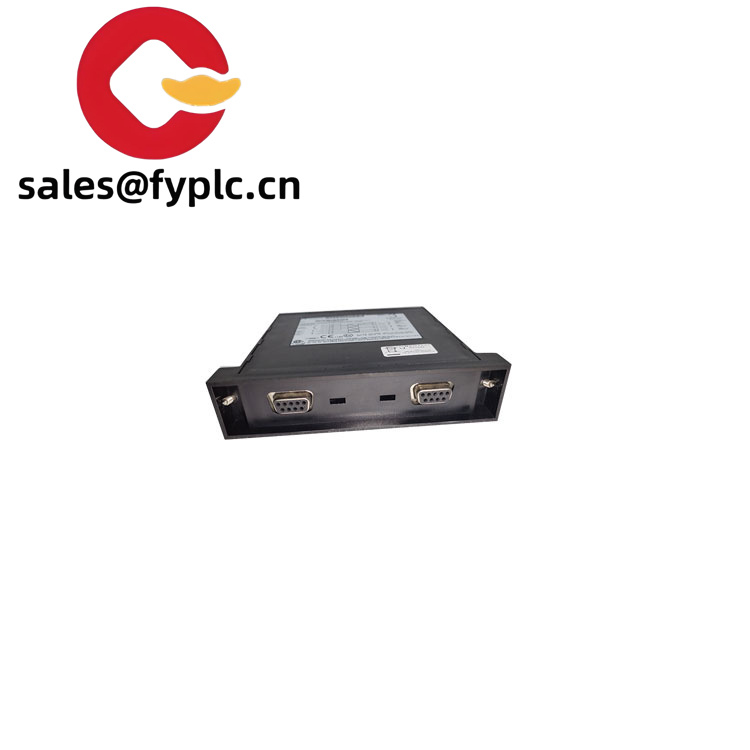

BENTLY 170190-01E Front Vibration Sensor

The BENTLY 170180-01-00 is primarily used as a monitoring module, interfacing seamlessly with a variety of sensors that detect vital parameters such as vibration, temperature, and displacement in industrial equipment. In large manufacturing plants, power generation facilities, and oil refineries, this module plays a crucial role in the overall monitoring and control infrastructure. For example, in a power plant, it can continuously monitor the vibration levels of turbines, which are essential for electricity generation. By collecting and analyzing real – time data, the BENTLY 170180-01-00 can detect early signs of potential mechanical issues, allowing operators to take proactive maintenance measures and prevent costly breakdowns. This not only minimizes unplanned downtime but also extends the lifespan of the equipment, optimizing the overall productivity of the plant.

|

Label

|

Specification

|

|

Model Number

|

170180-01-00

|

|

Brand

|

BENTLY

|

|

Type

|

Monitoring Module

|

|

Input Channels

|

Multiple channels for various sensor inputs

|

|

Sensor Types Supported

|

Vibration, temperature, displacement sensors etc.

|

|

Data Sampling Rate

|

High – speed sampling for accurate real – time data

|

|

Communication Protocols

|

Profibus, Modbus TCP, Ethernet/IP

|

|

Operating Temperature

|

-40°C to 85°C

|

|

Power Supply

|

24 V DC

|

|

Dimensions

|

Compact design for easy installation

|

|

Weight

|

Lightweight for convenient handling

|

|

Certifications

|

CE, UL, ISO compliant

|

|

IP Rating

|

IP65 for dust and water protection

|

For more information, please click on the following link:

AB 2711 series 2711-K6C15 touch screen accessories

Rockwell 1762-OW16 Safety Output Module Relay

Triconex 3009 Enhanced Main Processor (UMP) Module

Triconex 3101/Triconex3201 Triple Modular Redundant Main Processor

AB 2711-K6C5 touch screen human-machine interface function module

Allen Bradley 1769-L32C | Processor Analog Input/Output Module

ABB UFC718AE01-HIEE300936R0001 Power Control Equipment Module

Reviews

There are no reviews yet.