Description

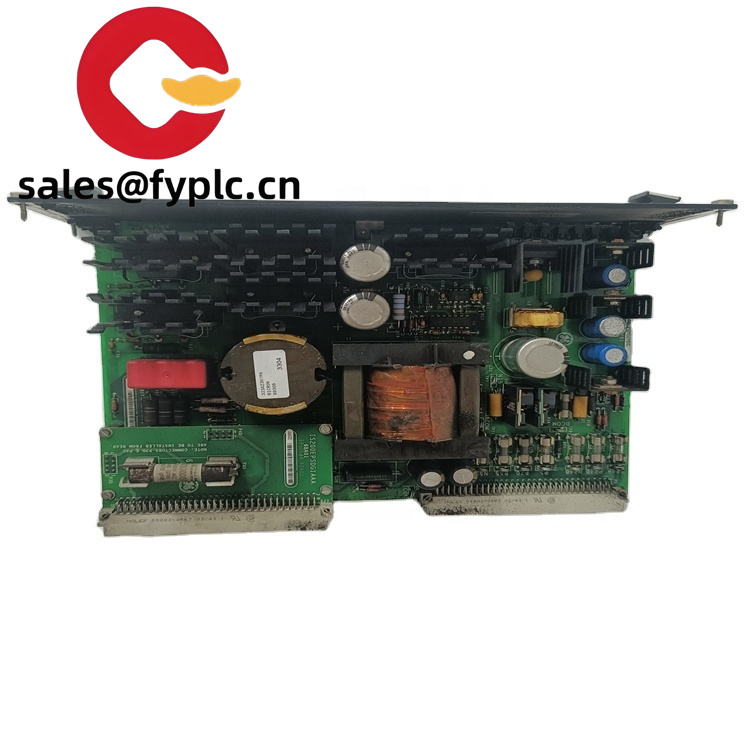

GE IS200DSPXH1DBC Digital Signal Processor Control Board

In the intricate ecosystem of industrial automation, precision and reliability are non-negotiable. The GE IS200DSPXH1DBC emerges as a critical component designed to meet these demands, serving as a high-performance Digital Signal Processor (DSP) Module within GE’s Speedtronic™ and Mark VIe control systems. Engineered for applications requiring real-time signal processing and control, this module excels in managing complex algorithms for turbine control, power generation, and heavy machinery regulation. Its primary function is to convert analog signals from sensors into digital data, process it with remarkable speed, and execute control commands to maintain optimal system performance.

| Label | Specification |

|---|---|

| Model Number | IS200DSPXH1DBC |

| Brand | GE |

| Type | Digital Signal Processor Module |

| Input Voltage | 24 VDC ±10% |

| Operating Temp | -40°C to +70°C |

| Communication | Serial (RS-232/485), Ethernet (Modbus TCP) |

| Mounting | Rack-mounted (compatible with GE control chassis) |

| Weight | 1.2 kg |

| Certifications | CE, UL, CSA |

| Dimensions | 177.8 mm × 101.6 mm × 25.4 mm |

| Processor | TI TMS320C6713 DSP (300 MHz) |

| Memory | 128 MB SDRAM, 16 MB Flash |

Functional Strengths & Design Advantages

4. Industrial Use Cases & Value Scenarios

For more information, please click on the following link:

AB 2711 series 2711-K6C15 touch screen accessories

Rockwell 1762-OW16 Safety Output Module Relay

Triconex 3009 Enhanced Main Processor (UMP) Module

Triconex 3101/Triconex3201 Triple Modular Redundant Main Processor

AB 2711-K6C5 touch screen human-machine interface function module

Allen Bradley 1769-L32C | Processor Analog Input/Output Module

ABB UFC718AE01-HIEE300936R0001 Power Control Equipment Module

Reviews

There are no reviews yet.