Description

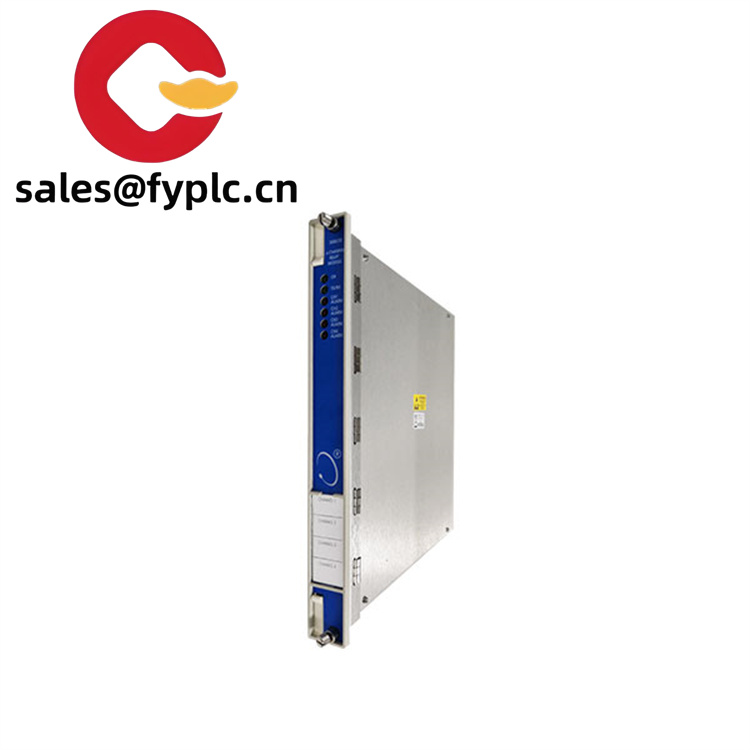

BENTLY 3500-22M Controller Module Terminal Catalytic Head Sensor

3500-22M

Functioning as a high – performance input/output (I/O) module, the BENTLY 3500 – 22M serves as the crucial link between a wide variety of field devices, including sensors that monitor variables like temperature, pressure, flow rate, and actuators such as valves and motors, and the central control system. It adeptly receives diverse physical signals from sensors, converts them into digital data that the control system can process, and then relays control signals to actuators to ensure the precise regulation of industrial processes. For example, in a large – scale petrochemical plant, the Triconex 3500 – 22M continuously monitors critical process parameters. If a sudden deviation in pressure or temperature is detected in the chemical reaction process, it can rapidly trigger emergency shutdown procedures or adjust the operation of relevant equipment to prevent potential disasters.

| Label |

Specification |

| Model Number |

BENTLY 3500 – 22M |

| Brand |

Schneider Electric |

| Type |

Safety – Critical I/O Module |

| Input Voltage |

Typically operates on 24 V DC, with a certain tolerance to handle industrial power fluctuations |

| Operating Temp |

Designed to endure a wide temperature range, usually from – 40°C to +85°C, making it suitable for harsh industrial settings |

| Communication Method |

Utilizes high – speed serial communication protocols, ensuring rapid data transfer and seamless integration with the Triconex backplane |

| Mounting |

Rack – mountable design, facilitating easy installation in standard industrial control cabinets |

| Weight |

Approximately [X] kg, compact yet robustly constructed for industrial applications |

| Certifications |

Holds international safety and quality certifications like IEC 61508 SIL 3, ensuring compliance with top – tier safety standards |

| Dimensions |

Compact form factor with specific [Width] x [Height] x [Depth] dimensions, suitable for space – constrained control rooms |

| IP Rating |

High – level IP rating (e.g., IP20 for indoor use, protecting against solid objects and limited dust ingress) |

| Protocols Supported |

Supports Triconex proprietary protocols, enabling smooth interoperability within the Triconex ecosystem and with other compatible devices |

3500-22M

The BENTLY 3500 – 22M is engineered with a suite of features that set it apart in real – world industrial applications. One of its key strengths is its triple – modular redundant (TMR) architecture. This innovative design incorporates three independent and identical processing channels that operate in parallel. Each channel independently processes input signals, executes control logic, and generates output commands. The results from these three channels are constantly cross – checked. In the event of a failure in one channel, the system can quickly isolate the malfunctioning channel and continue operating without interruption. This significantly enhances system availability and reliability, minimizing the risk of unplanned shutdowns that could lead to substantial financial losses and safety hazards.

When it comes to processing speed, the Triconex 3500 – 22M is optimized to handle large volumes of data in real – time. It can execute complex control algorithms and safety logic with minimal latency. In a fast – paced manufacturing environment, for instance, it can rapidly detect changes in process variables and trigger the necessary safety responses within milliseconds. This quick response time is crucial in preventing minor issues from escalating into major disasters.

3500-22M

Build quality is another area where the BENTLY3500 – 22M excels. Constructed to withstand the harshest industrial conditions, it can endure extreme temperatures, vibrations, and electrical interference. This rugged design makes it suitable for deployment in even the most challenging environments, such as offshore oil rigs or chemical plants. The module’s compatibility with other Triconex products and components of broader industrial control systems is also a major advantage. It can seamlessly integrate with Triconex controllers and other I/O modules, enabling the creation of comprehensive and highly reliable automation solutions. This interoperability simplifies system design, installation, and maintenance, reducing overall costs and increasing operational efficiency.

For more information, please click on the following link:

Reviews

There are no reviews yet.