Description

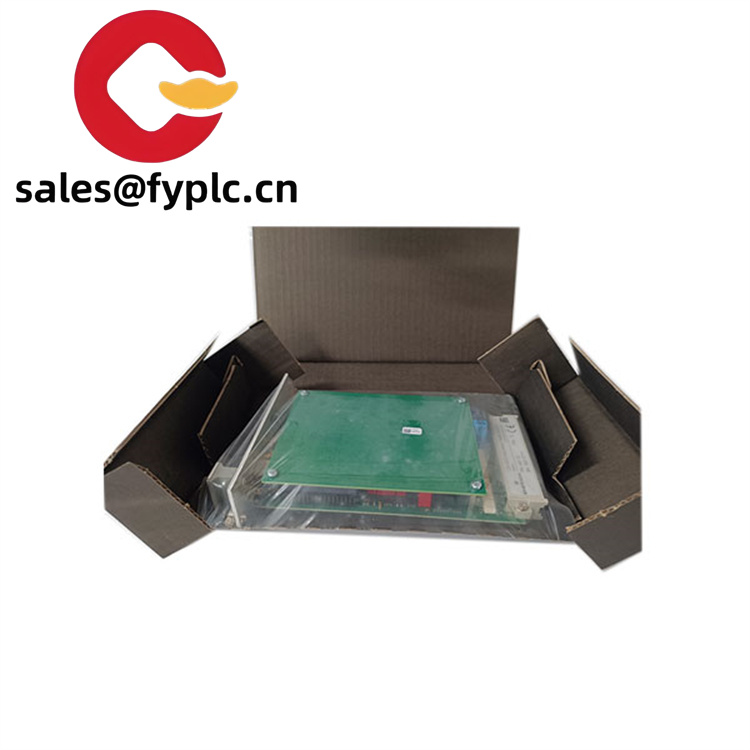

EMERSON A6410 Control System Mainboard Interface Module Dual Channel Valve

A6410

The EMERSON A6410 excels in measuring two vital parameters: valve position and casing expansion in steam turbines, gas compressors, and other heavy-duty rotating equipment. For instance, it monitors the linear movement of main steam inlet valves, translating mechanical motion into proportional electrical signals (e.g., 4–20 mA) that align with plant-wide control systems. Simultaneously, it tracks casing expansion during start-up and operation, a critical function in preventing shaft-to-casing rubs caused by uneven thermal growth. By combining these measurements, the A6410 acts as a frontline defender against catastrophic failures, ensuring compliance with API 670 standards for machinery protection.

| Label |

Specification |

| Model Number |

A6410 |

| Brand |

EMERSON |

| Type |

Dual-Channel Valve & Casing Expansion Monitor |

| Input Voltage |

24 VDC (±10% tolerance) |

| Operating Temp |

-40°C to +85°C (industrial-grade thermal resilience) |

| Communication |

Analog outputs (4–20 mA, 0–10 V) for DCS/SCADA integration |

| Mounting |

1-slot, 3U rackmount (compatible with AMS 6500 chassis) |

| Weight |

1.2 kg (compact design for space-constrained control rooms) |

| Certifications |

API 670, CE, CSA (global safety and reliability standards) |

| Dimensions |

177.8 mm x 48.3 mm x 241.3 mm (standard rackmount form factor) |

| Input Type |

LVDT (Linear Variable Differential Transformer) sensors |

| Resolution |

0.1% of full scale (valve position), 0.01 mm (casing expansion) |

| Alarm Relays |

2 per channel (configurable for high/low thresholds) |

A6410

The EMERSON A6410 is engineered for precision and durability, starting with its dual-channel architecture that supports simultaneous monitoring of valve dynamics and casing movement. Its high-resolution LVDT signal conditioning ensures accurate measurements even in harsh environments, filtering out electrical noise and thermal drift. For example, in a gas compressor station, the module can detect casing expansion discrepancies as small as 0.05 mm, alerting operators to potential misalignment before it escalates into a mechanical failure.

Built to withstand industrial rigors, the

A6410 features rugged circuitry with surge protection and galvanic isolation, safeguarding against voltage spikes and ground loops. This resilience is critical in power plants where transient electrical disturbances are common. Operators benefit from its plug-and-play compatibility with Emerson’s AMS Suite software, enabling remote configuration of alarm setpoints and trend analysis. The module’s intuitive front-panel indicators (LEDs for power, alarm, and fault status) simplify on-site diagnostics, reducing mean time to repair (MTTR) in critical scenarios.

A6410

Interoperability is another cornerstone of the

A6410. Its analog outputs seamlessly integrate with PLCs, DCS systems, and historians, such as Emerson’s DeltaV or third-party SCADA platforms. This flexibility allows plant engineers to create unified monitoring ecosystems, where valve position data from the

A6410 can be cross-referenced with vibration metrics from other AMS 6500 modules (e.g., the A6110 vibration monitor) to diagnose complex machinery issues.

For more information, please click on the following link:

Reviews

There are no reviews yet.