Description

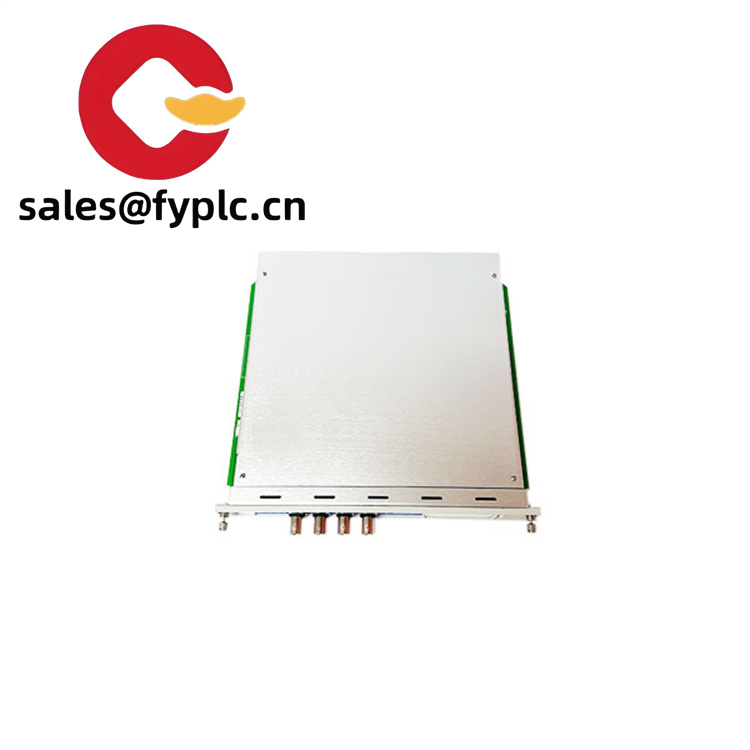

BENTLY 350064M Dynamic Pressure Monitor

In the heart of modern industrial systems, where reliability and accuracy are non-negotiable, the Bently Nevada 3500/64M Temperature Monitoring Module emerges as a critical component for safeguarding machinery and optimizing operations. Engineered to meet the demands of harsh environments, this module serves as a cornerstone in predictive maintenance strategies, enabling real-time temperature surveillance across a wide range of industrial applications. Whether integrated into power generation turbines, chemical processing plants, or advanced manufacturing lines, the 3500/64M ensures seamless data acquisition and control, making it an indispensable asset for industries prioritizing uptime and efficiency.

| Label | Specification |

|---|---|

| Model Number | 3500/64M |

| Brand | Bently Nevada |

| Type | Four-Channel Dynamic Pressure and Temperature Monitoring Module |

| Input Voltage | 24V DC |

| Operating Temp | -25°C to +85°C |

| Communication Method | Analog (0–5V DC), Digital (RS-485) |

| Mounting | DIN rail |

| Weight | 350 g |

| Certifications | CE, ISO 9001 |

| Dimensions | 4.5 x 15 x 25 cm |

| IP Rating | IP65 |

| Protocols Supported | Modbus RTU, Bently Nevada Proprietary Protocol |

What sets the Bently Nevada 3500/64M apart is its unwavering commitment to performance and adaptability. Engineered with electromagnetic compatibility (EMC) and full-digital signal processing, the module resists interference in high-noise environments, ensuring consistent data integrity . Its wide operating temperature range (-25°C to +85°C) makes it suitable for extreme conditions, from arctic oil rigs to scorching steel mills. Operators benefit from its modular design, which allows easy integration into existing systems without extensive reconfiguration.

The Bently Nevada 3500/64M thrives in industries where temperature and pressure fluctuations directly impact operational safety and efficiency. In power generation, it monitors turbine bearings to detect overheating, a common precursor to mechanical failure. By alerting operators to 异常温升,the module reduces unplanned downtime and extends component longevity. Similarly, in chemical processing plants, it ensures reactor temperatures remain within critical limits, preventing hazardous runaway reactions.

Compatible and Related Models

For more information, please click on the following link:

ABB PCD232A Exciter Control Module Unit

Motorola MVME2400 Sandwich Board PCI Processor

NI PCI-5421 Signal Acquisition Card Signal Generator

PROSOFT MVI56E-MNETC Communication Multi Series Module

GE PCH1026 Vibration Sensor Digital Structural Vibration Monitor

Reviews

There are no reviews yet.