Description

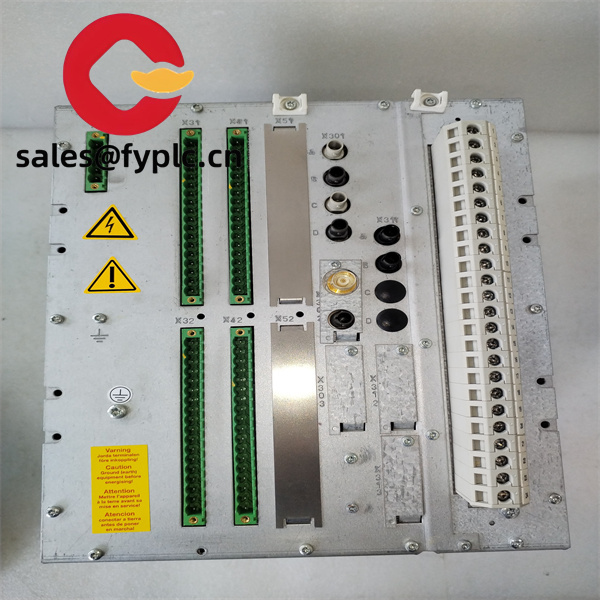

ABB REG670 digital relay internal power module

In the complex world of industrial control systems, safeguarding equipment and ensuring seamless operations is crucial. The ABB REG670 steps in as a high – performance digital protection and control relay, designed to meet the stringent demands of modern power and industrial automation setups. This device is a cornerstone for protecting and monitoring electrical equipment, making it an essential part of various industrial applications.

The ABB REG670 is engineered to offer comprehensive protection and control capabilities. It serves as a vigilant guardian for power transformers, generators, motors, and other critical electrical components in high – voltage substations. By constantly monitoring electrical parameters, it can quickly detect any anomalies and take appropriate actions. In essence, the REG670 acts as the nervous system of an industrial control system, ensuring that every component functions smoothly and safely. It fits seamlessly into broader industrial control systems, whether it’s a large – scale power generation facility or a complex manufacturing plant, providing the necessary protection and control functions to keep the operations running without a hitch.

|

Label

|

Specification

|

|

Model Number

|

REG670

|

|

Brand

|

ABB

|

|

Type

|

Digital Protection and Control Relay

|

|

Input Voltage

|

Up to 800 kV (rated voltage for high – voltage applications)

|

|

Operating Temp

|

– 40°C to + 70°C, suitable for a wide range of environmental conditions

|

|

Communication Method

|

Supports IEC 61850, Modbus, DNP3, and other industry – standard protocols

|

|

Mounting

|

Can be installed in a variety of ways to suit different substation setups

|

|

Weight

|

[Weight information if available]

|

|

Certifications

|

Complies with relevant international standards for safety and performance

|

Functional Strengths & Design Advantages

The ABB REG670 is a powerhouse when it comes to performance. Its advanced protection algorithms are designed to detect faults with lightning – fast speed. In case of an overcurrent or a short – circuit, the REG670 can quickly isolate the faulty section, minimizing the impact on the rest of the system. This rapid response not only protects the equipment from damage but also helps in maintaining the continuity of power supply.

Built with high – quality materials, the REG670 is incredibly resilient. It can withstand harsh industrial environments, including extreme temperatures, high humidity, and electromagnetic interference. This robustness ensures that the relay continues to function optimally even in the most challenging conditions.

Interoperability is another feather in the cap of the ABB REG670. With support for multiple communication protocols, it can easily integrate with other substation equipment. This allows for seamless data exchange and coordinated control, enhancing the overall efficiency of the industrial control system. Whether it’s communicating with a SCADA system or other intelligent devices, the REG670 can do it with ease.

Industrial Use Cases & Value Scenarios

In power generation plants, the ABB REG670 plays a pivotal role. For example, in a thermal power plant, it protects the generators from various electrical faults. By providing differential protection, it can accurately detect internal short – circuits within the generator. This not only prevents costly damage to the generator but also ensures continuous power generation, which is crucial for meeting the energy demands.

In manufacturing industries, especially those with large – scale production lines, the REG670 is used to protect motors. Motors are the workhorses of these plants, and any malfunction can lead to significant production losses. The REG670’s overcurrent and overload protection functions keep these motors in check. It monitors the current flowing through the motors and, if an abnormal increase is detected, it quickly shuts down the motor to prevent overheating and subsequent damage. This helps in maintaining the smooth operation of the production line, reducing downtime, and increasing overall productivity in the industrial automation setup.

For more information, please click below to learn more:

Reviews

There are no reviews yet.