Description

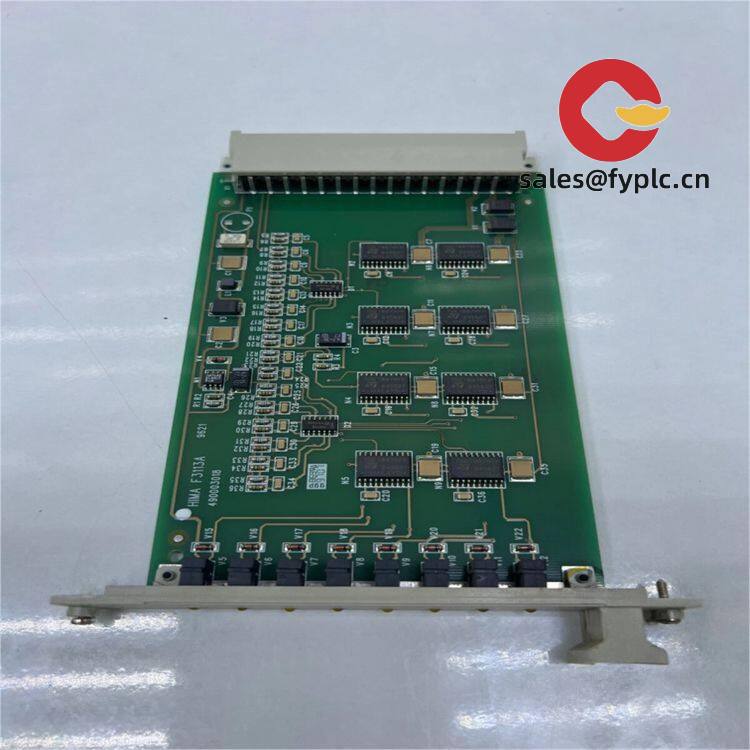

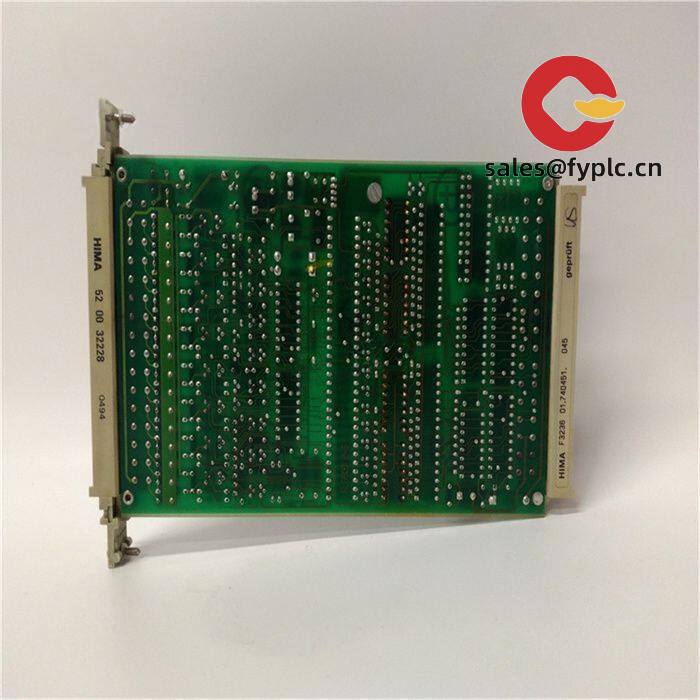

HIMA F3221 Refurbished Input Module – Cost‑Effective Safety I/O for HIMA Systems

The HIMA F3221 is a safety input module designed for HIMA safety PLC platforms. If you’re keeping a mature safety system running without the cost and delay of a full hardware refresh, a professionally refurbished F3221 is often the most practical path—tightens downtime, trims spend, and keeps your existing logic untouched.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: In‑stock typically ships in 1 week; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Safety‑rated input processing – Designed for HIMA safety applications, typically used for 24 VDC discrete signal acquisition from field devices.

- Backplane integration – Communicates via the HIMA system backplane, so no external configuration ports are required on the card itself.

- Diagnostics and status LEDs – You might notice that channel and module health are quickly visible, making commissioning and troubleshooting faster in many cases.

- Service-friendly design – From my experience, F‑series modules allow quick swap in a powered chassis when the system architecture permits redundancy and proper procedures.

- Refurbished for reliability – Fully cleaned, inspected, electrically tested, and packaged with ESD protection; typically includes replaced wear items like terminal screws if needed.

- Lifecycle support – Ideal for plants standardizing on HIMA where spares are needed to maintain legacy safety logic without revalidation work.

Technical Specifications

| Brand / Model | HIMA F3221 |

| HS Code | 8538.90 (Parts for industrial control apparatus) |

| Power Requirements | Supplied via HIMA system backplane (24 VDC system power, module consumption dependent on configuration) |

| Operating Temperature | Typically 0 to +60°C, non‑condensing ambient |

| Signal Input/Output Types | Digital input module, commonly used for 24 VDC discrete signals (e.g., limit switches, relays, dry contacts via external supply) |

| Communication Interfaces | System backplane bus (no external fieldbus on module) |

| Installation Method | Plug‑in card for HIMA rack/chassis with front terminal connection |

Application Fields

The F3221 fits right into safety‑critical environments where deterministic input capture is essential. Typical uses include:

- Oil & Gas: ESD, HIPPS, fire & gas input collection

- Chemical & Pharma: reactor interlocks, emergency stop networks

- Power Generation: turbine trip, boiler protection inputs

- Industrial Machinery: safety gates, light curtains (through appropriate interface relays)

- Rail and Infrastructure: trackside or plant safety I/O where HIMA systems are standardized

Advantages & Value

- Cost savings – Refurbished typically saves 30–60% versus new while keeping the same form, fit, and function.

- Minimal process risk – No re‑engineering of logic or wiring; it drops into the existing HIMA rack.

- Shorter lead times – Useful when unplanned downtime or shutdown windows can’t wait for long factory lead times.

- Verified quality – Electrical test, burn‑in where applicable, and visual inspection help catch latent faults before shipment.

- Support you can use – From my experience, a quick configuration check and as‑installed documentation review prevents most commissioning hiccups.

“We swapped an F3221 during a hot‑standby maintenance window—no PLC logic changes needed. The diagnostics matched immediately and the loop walk‑down finished in a single shift.” — Maintenance Supervisor, Petrochem

Installation & Maintenance

- Environment – Install in a rated control cabinet with adequate ventilation; keep within the stated ambient temperature and humidity.

- Wiring – Use correctly rated 24 VDC signal wiring; segregate from high‑voltage cables; apply shielded pairs for noisy areas and land shields per site EMC practice.

- Handling – Observe ESD procedures; de‑energize the rack unless your system is engineered for online replacement and your MOC allows it.

- Commissioning – Verify channel polarity, commoning, and safety logic; confirm module revision compatibility with the controller firmware.

- Routine maintenance – Periodic terminal re‑torque, dust removal with dry air, visual inspection of connectors; align firmware/parameters with site master backup.

- Proof testing – In most cases, follow your SIL proof test interval and record channel response times and diagnostics for your safety dossier.

Quality & Certifications

- Manufacturer compliance typically includes CE; many HIMA F‑series modules are designed for use in safety systems meeting IEC 61508/IEC 61511 architectures (module certification details depend on revision).

- RoHS alignment for the original equipment is common; refurbished units are tested to functional criteria before shipment.

- 365‑day warranty on the refurbished module.

- Test reports or photos from the bench can be provided upon request.

Need a matching spare? If you’re pairing the F3221 with complementary HIMA modules (CPU, power supply, or digital outputs), share your rack type and CPU model and we’ll align revisions to avoid compatibility surprises.

Reviews

There are no reviews yet.