Description

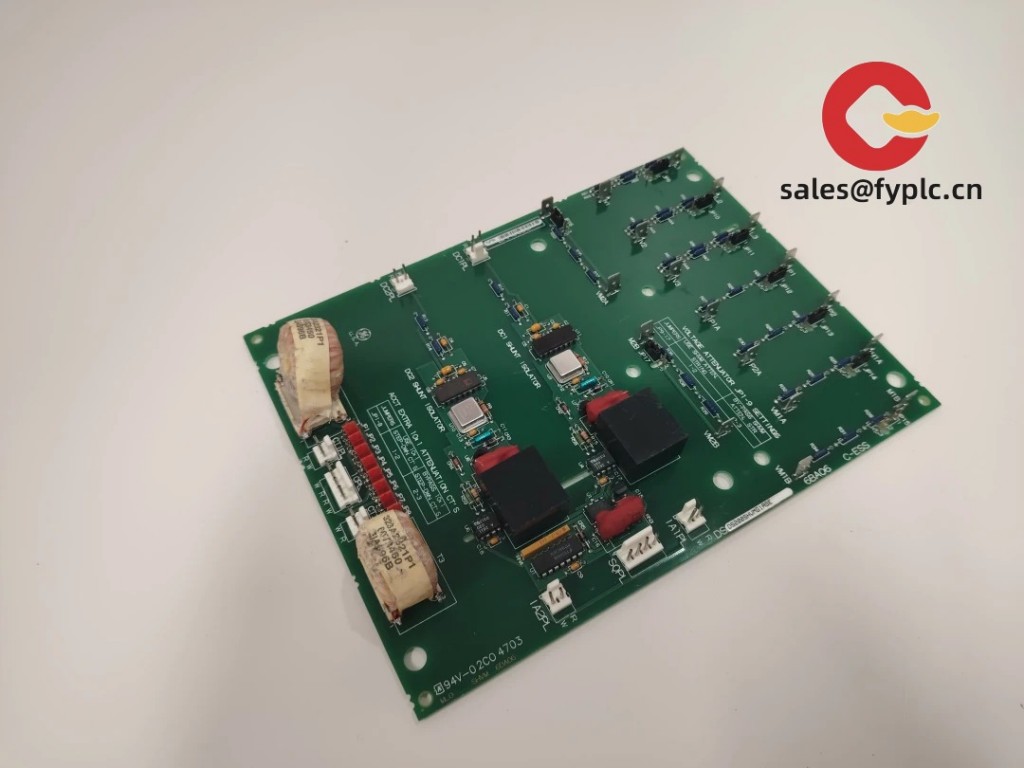

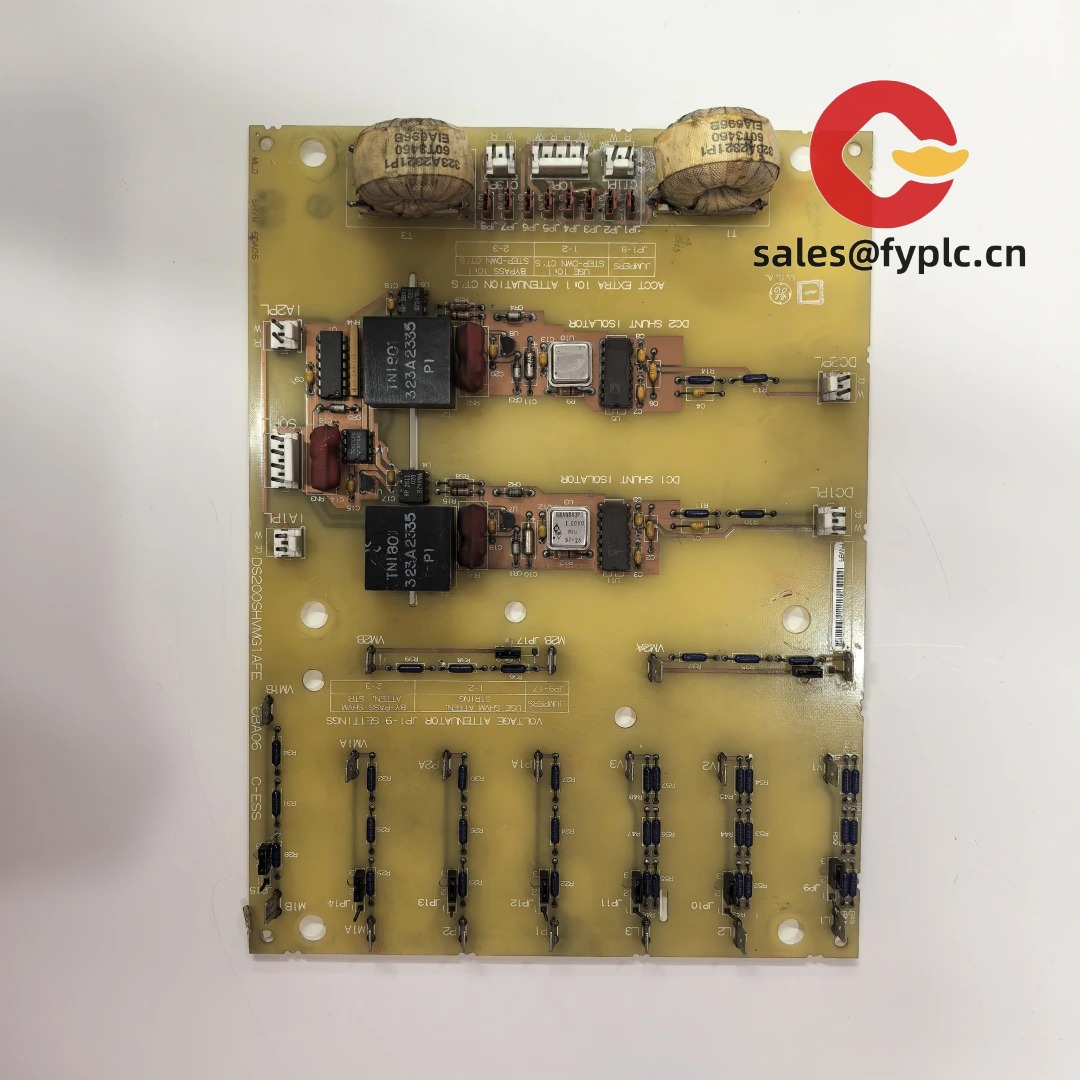

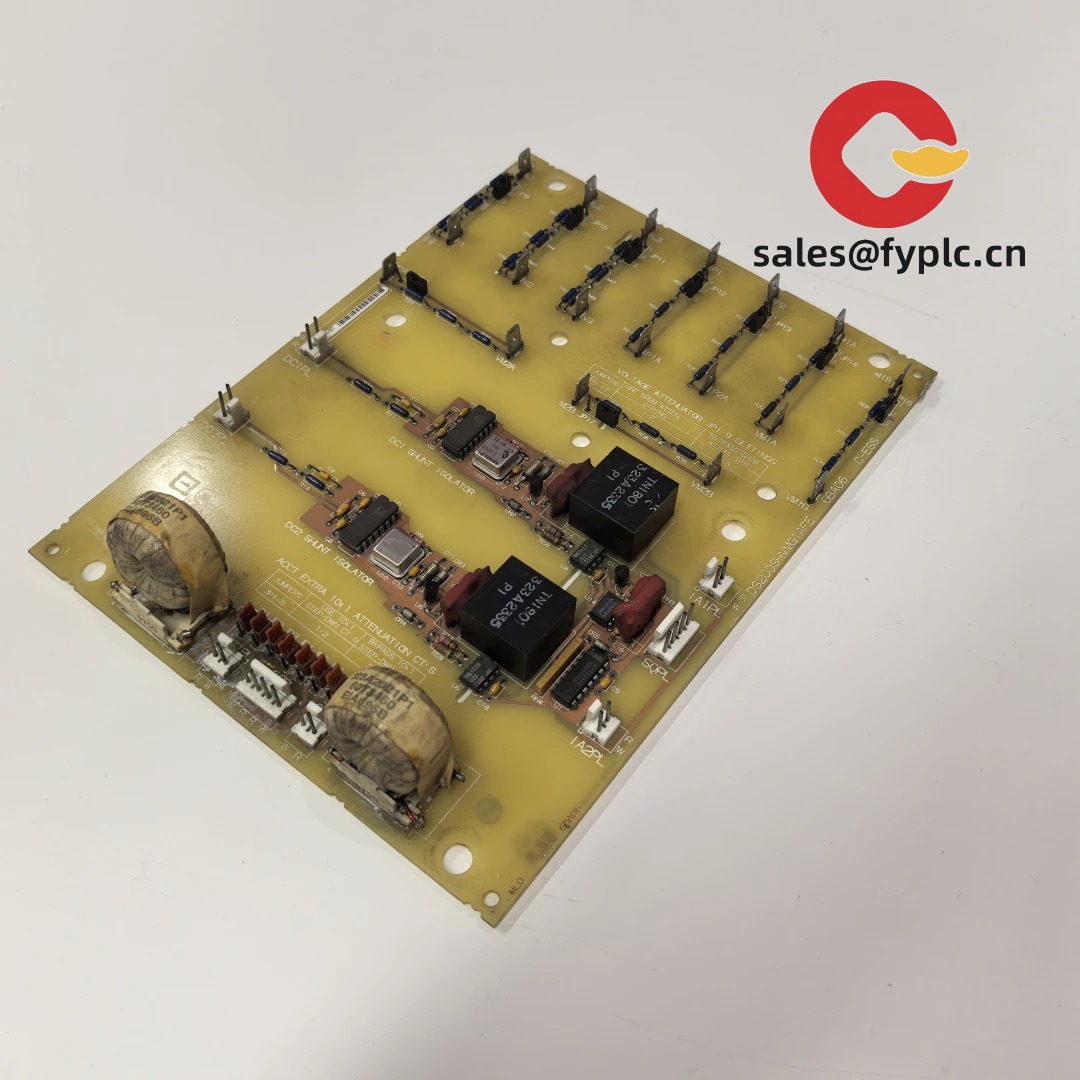

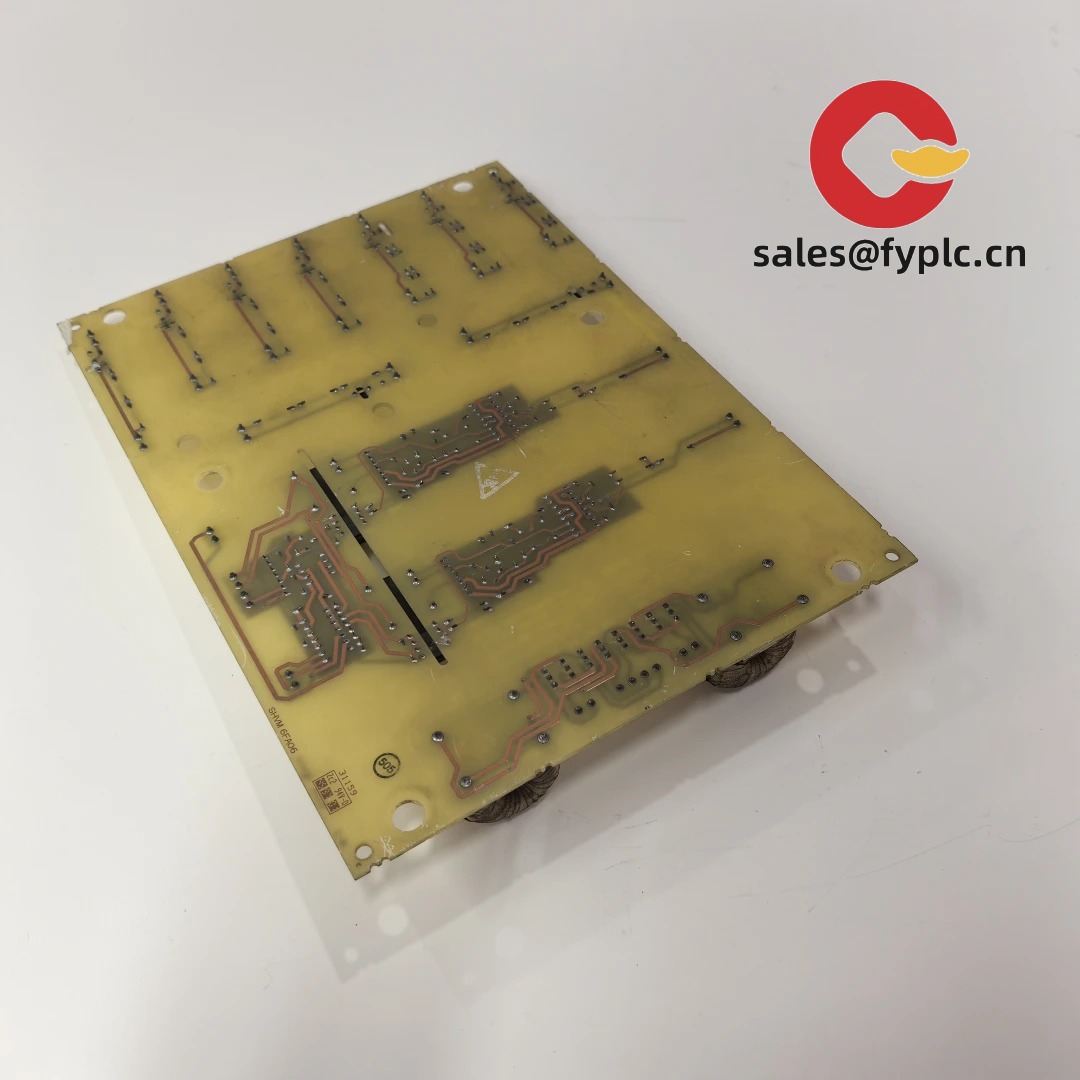

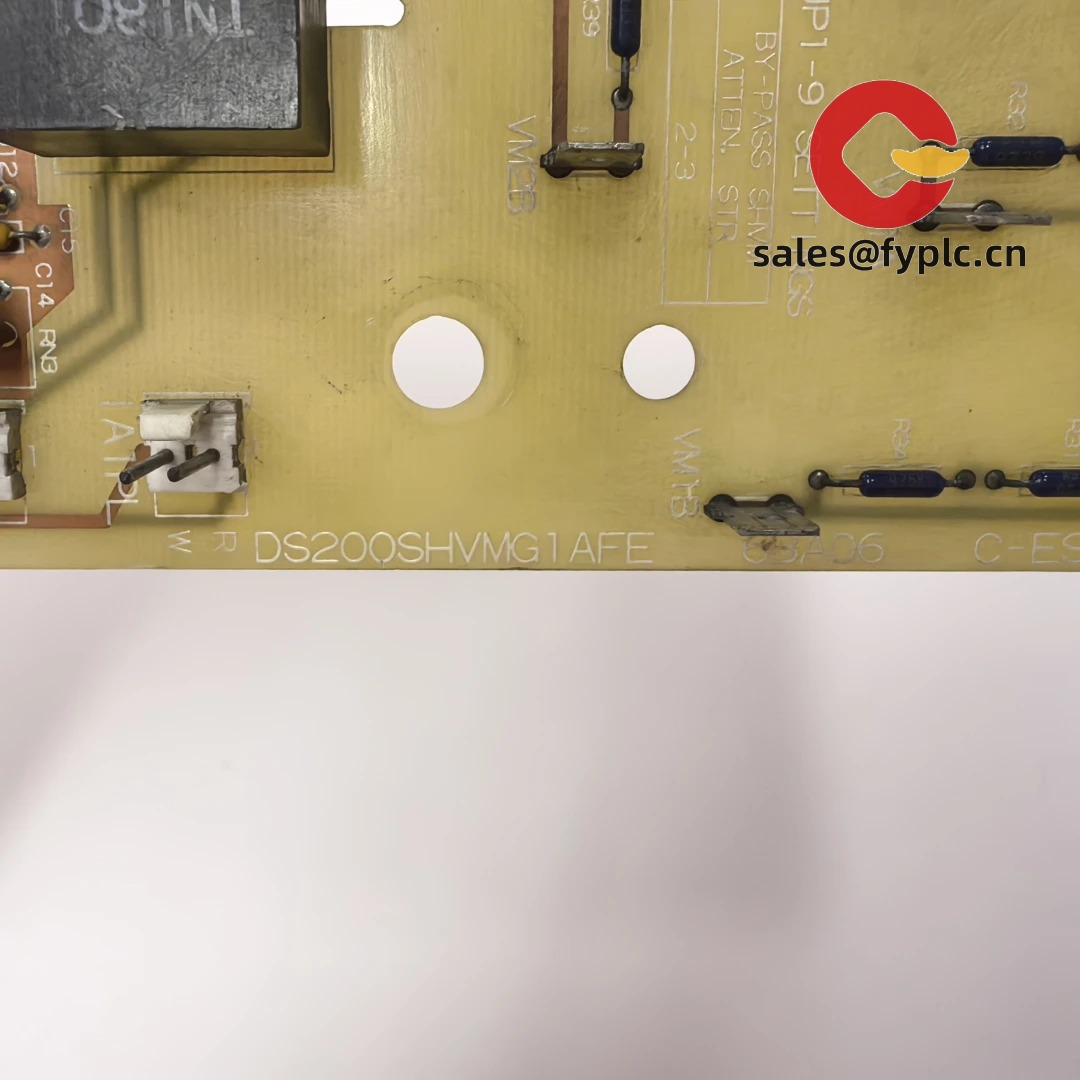

GE DS200SHVMG1AFE – SHVM High‑Voltage Measurement/Interface Board for GE Drive Cabinets

The GE DS200SHVMG1AFE is a Group 1 SHVM board used inside GE DC/AC drive and exciter cabinets. It functions as a high‑voltage measurement/interface module tied to the power section—typically conditioning bridge voltage feedbacks, supporting permissives, and coordinating interface points between the control core and the power stack. From my experience, when this card ages, you might notice voltage feedback chatter, inconsistent start‑permit logic, or nuisance trips under heat or vibration. One thing I appreciate is the service‑friendly connector layout; it seems designed for a like‑for‑like swap during a short planned stop, keeping wiring and harness routing undisturbed.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in‑stock; no more than one month at the latest

- Payment method: 50% advance payment; full payment for delivery

- Express delivery methods: FedEx / UPS / DHL

- Compatibility check: Share the cabinet nameplate and a clear photo of the SHVM label (DS200SHVMG1AFE); this typically locks the correct revision quickly.

Key Features

- High‑voltage feedback interface – Conditions bridge voltage signals for the control core so regulation stays stable in most cases.

- Permissive and protection paths – Supports cabinet permissives and related protection logic to keep interlocks consistent.

- Group G1, revision AFE – Hardware group and revision matching matter; we help verify against your cabinet build.

- Drop‑in spare – Like‑for‑like replacement that typically avoids rewiring and preserves parameterization.

- Service‑friendly design – Keyed connectors, labeled headers, and accessible standoffs make changeouts straightforward.

- Lifecycle extension – A practical way to stabilize legacy GE drives/exciters without a full retrofit project.

Technical Specifications

| Brand / Model | GE DS200SHVMG1AFE (SHVM High‑Voltage Interface) |

| HS Code | 8538.90 (Parts suitable for electrical control apparatus) |

| Power Requirements | Powered from host low‑voltage rails; +5 V and ±15 V are common in DS200‑series cabinets |

| Operating Temperature | Typically 0…55 °C in a clean, ventilated, non‑condensing enclosure |

| Signal I/O Types | Conditioned high‑voltage measurement inputs, permissive/status lines via harness/backplane connectors (channel set depends on cabinet build) |

| Communication Interfaces | Internal harness/backplane only; external fieldbus handled by companion control boards (e.g., LDCC) |

| Installation Method | Plug‑in board secured with standoffs/screws; keyed connectors prevent mis‑seating |

Application Fields

Common in GE DC2000/AC2000 drives and, in many cases, EX‑series exciters used in metals processing, paper & converting, mining conveyors, oil & gas pumps/compressors, cranes/hoists, and large process fans. A typical scenario is sporadic undervoltage alarms or start‑permit drops after heat soak—replacing DS200SHVMG1AFE often stabilizes high‑voltage measurement paths without touching PLC logic.

Advantages & Value for Procurement

- Reliability – Restores clean voltage feedback and consistent permissive signaling, reducing nuisance trips.

- Compatibility – Built for DS200‑series cabinets; we verify group (G1) and revision letters (AFE) before shipment.

- Cost control – Board‑level maintenance is typically far cheaper than a cabinet retrofit and shortens recommissioning.

- Predictable downtime – Drop‑in mechanics and labeled connectors keep the swap inside a tight maintenance window.

- Technical backup – Guidance on harness mapping, revision matching, and post‑swap checks to lower risk.

Installation & Maintenance

- Cabinet standards – Install in a clean, dry, ventilated enclosure. Keep ambient 0…55 °C; avoid condensation and conductive dust.

- Safety & isolation – Lockout/tagout, wait for DC bus discharge, and confirm zero energy. Be mindful of stored charge in snubbers and HV circuits.

- ESD handling – Use an antistatic wrist strap; handle the board by its edges and avoid touching component pins.

- Harness seating – Mark positions, fully seat keyed connectors, and check PE/ground continuity and strain relief.

- Functional checks – After swap, verify permissives, confirm voltage measurement stability, run a controlled ramp, and monitor alarms.

- Routine care – Annual dust removal, connector inspection/re‑seating, and event‑log review; firmware tasks apply to companion control boards, not the SHVM itself.

Quality & Certifications

- Used within CE‑conformant drive assemblies; the module forms part of the certified system.

- UL recognition typically applies at the complete drive level.

- RoHS‑aligned materials/processes in many cases for GE electronic spares.

- Manufactured under ISO 9001 quality systems at the OEM level.

- Warranty: 12 months (365 days) against functional defects under normal operation.

A maintenance engineer on a rolling mill told us this SHVM swap stopped intermittent undervoltage alarms that only appeared after weekend heat soak. If you can send the cabinet nameplate and a clear photo of your DS200SHVMG1AFE label, we’ll confirm compatibility, reserve stock, and align shipment with your maintenance window.

Reviews

There are no reviews yet.