Description

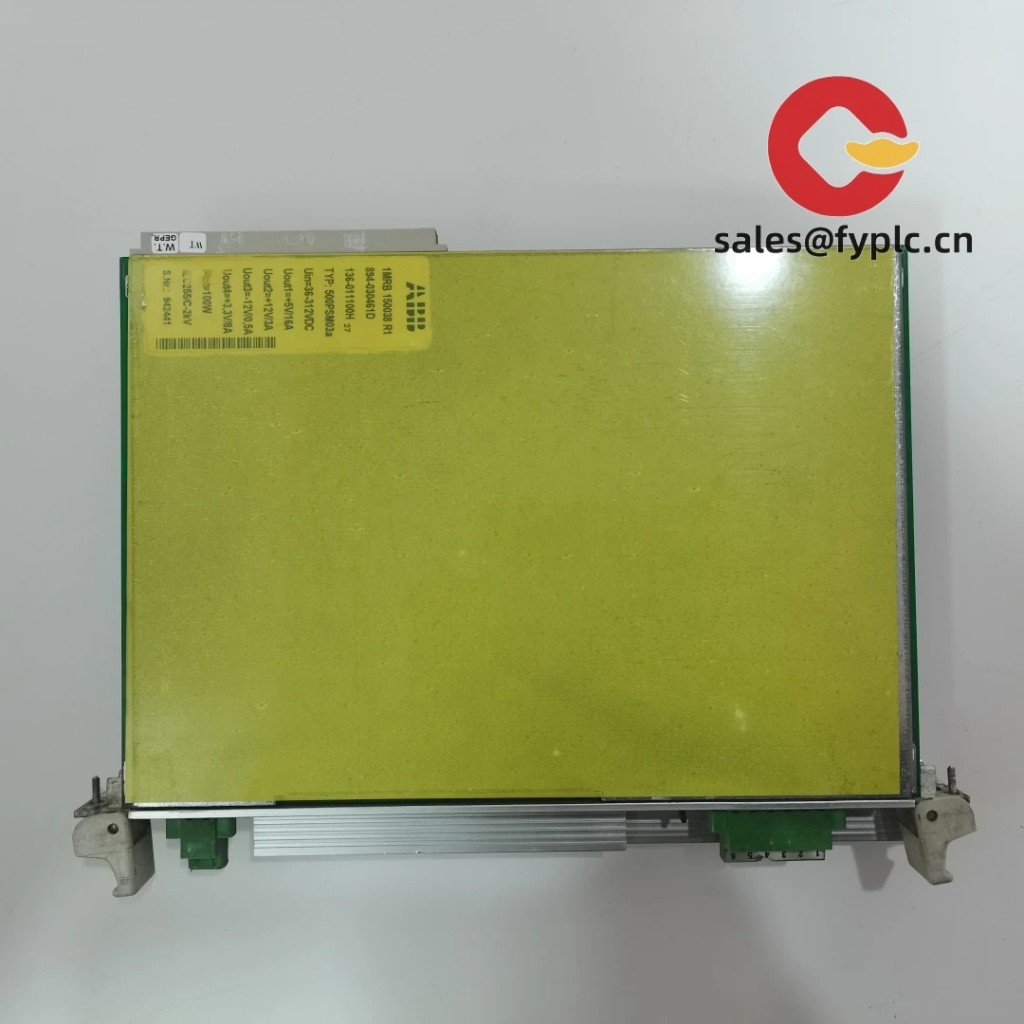

1MRB150020R1102 is a communication interface module in ABB’s AC500 series industrial automation systems. Its core function is to solve the interoperability issues between different devices and protocols in industrial scenarios. Serving as a “data bridge” between the control system and field devices, it is suitable for small to large industrial automation projects. Below is its detailed product information:

1. Core PositioningAs a dedicated communication module for the AC500 series, its core function is to break the protocol barriers of industrial equipment, enabling cross-protocol data interaction between PLCs, sensors, actuators, and host computers. It supports the networking and remote monitoring of distributed control systems and is a key component for ensuring smooth data flow in automation systems.

Core Features

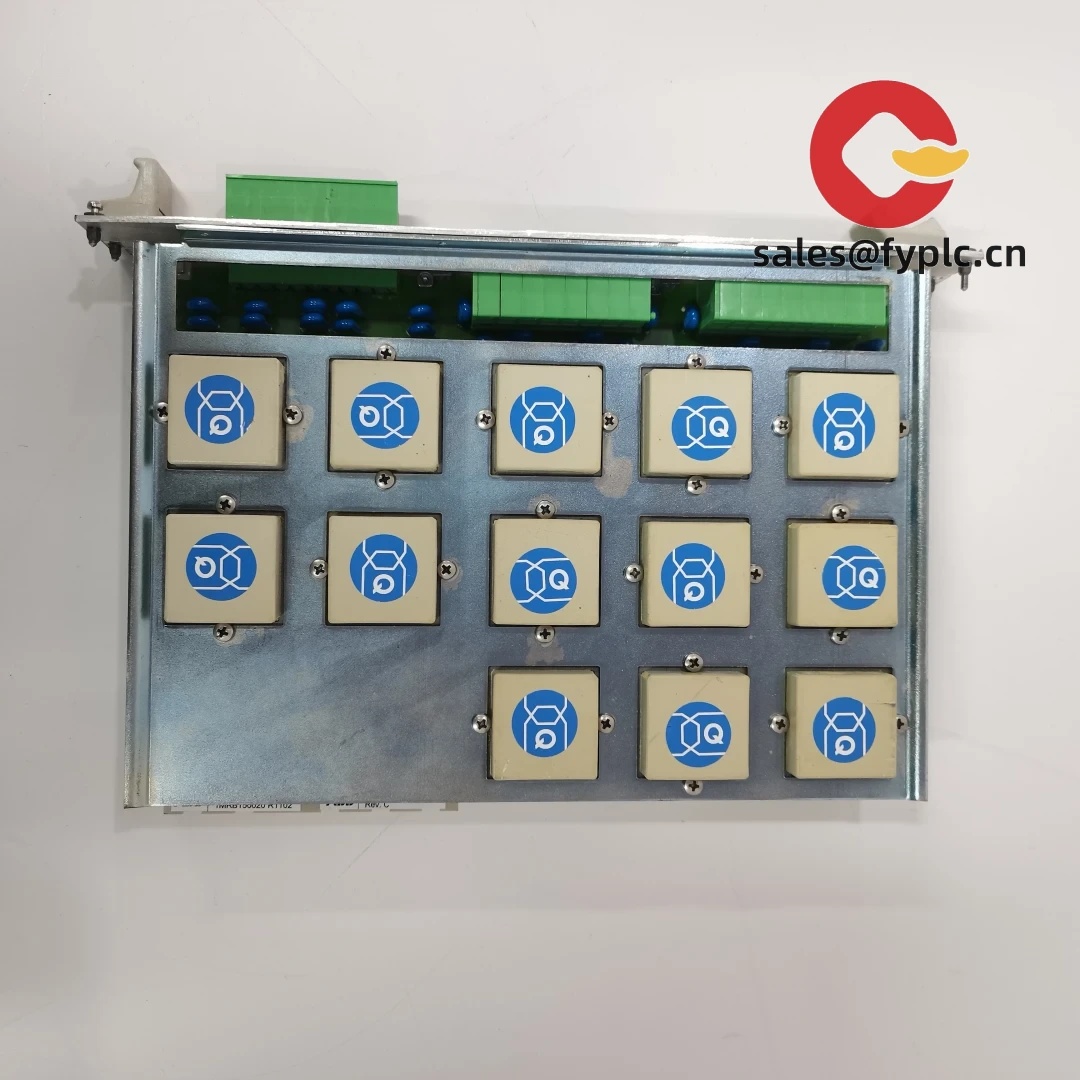

1. Multi-Protocol Compatibility and Conversion: Supports dual-protocol systems to accommodate both new and legacy devices: Ethernet Protocols: Ethernet/IP, Profinet, Modbus TCP, suitable for high-speed data transmission (e.g., remote monitoring, large data volume collection); Fieldbus Protocols: PROFIBUS DP, Modbus RTU (RS485 interface), compatible with traditional industrial equipment (e.g., older variable frequency drives, sensors); Equipped with gateway functionality to enable bidirectional data conversion between different protocols (e.g., signal exchange between Modbus TCP and PROFIBUS DP).

2. Distributed Networking and Data Routing: Can act as a master station connecting multiple slave devices (e.g., distributed I/O modules, smart instruments), supporting star and bus-type industrial networks; supports directed data forwarding to prioritize control commands and other critical data, reducing latency.

3. Real-Time Performance and Redundancy: Supports industrial-grade real-time communication (cycle ≤10ms) to meet synchronization requirements for device coordination; some versions feature dual network port redundancy design, automatically switching in case of a single link failure to avoid communication interruptions.

4. Fault Diagnosis and Status Monitoring: Built-in self-diagnosis functions to monitor communication links, module power supply, and protocol matching status; front-panel LED indicators (Power, Operation, Fault, Communication) provide intuitive feedback on operational status, facilitating quick problem identification (e.g., link disconnection, protocol incompatibility).

Product Advantages

1. Wide Compatibility: Not only compatible with ABB AC500 series PLCs and I/O modules, but also compatible with third-party devices such as Siemens and Schneider (supports standard industrial protocols). It can be directly integrated into existing systems, reducing the cost of upgrades and renovations.

2. High Reliability: Industrial-grade components + anti-interference design, capable of withstanding vibration (compliant with IEC 60068-2-6) and impact (compliant with IEC 60068-2-27), with a mean time between failures (MTBF) ≥ 100,000 hours, suitable for 24-hour continuous operation scenarios.

3. Strong Ease of Use: Supports ABB Automation Builder configuration software, allowing graphical configuration of protocol parameters and network topology without complex programming; supports hot swapping (if allowed by the system), enabling maintenance without shutting down.

4. Flexible Expansion: Can support new protocols via software upgrades (e.g., connecting EtherCAT devices in the future) without replacing hardware, meeting the evolving device requirements in industrial digital transformation.

Typical Application Scenarios:

1. Manufacturing: Automotive assembly lines, SMT production lines for electronic components, food packaging lines, used to connect robotic arms, conveyor line controllers, and quality inspection equipment, enabling coordinated control of multiple devices and data aggregation.

2. Process Industry: Chemical reactors, oil pipelines, water treatment plants, connecting pressure/flow sensors and valve actuators to transmit field data to the DCS system, while issuing control commands (such as valve opening adjustments).

3. Energy Industry: Photovoltaic inverters, wind turbine pitch systems, substation distribution equipment, uploading power generation/distribution data to the monitoring center via Ethernet and supporting remote start/stop control.

4. Building Automation: Air conditioning systems, lighting controllers, and security devices in large commercial complexes and industrial plants, establishing a unified communication network for centralized monitoring and energy-efficient scheduling.

Reviews

There are no reviews yet.