Description

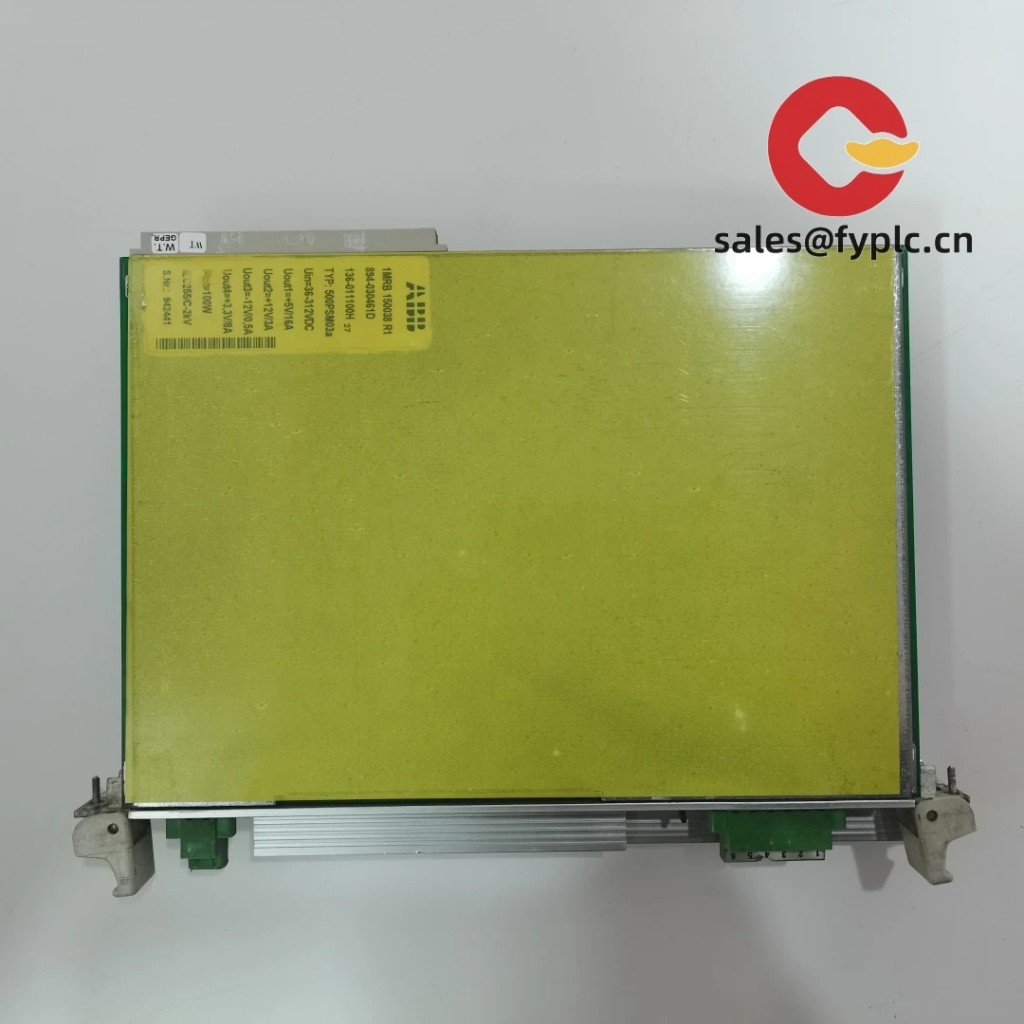

500CMP04 HE401314/0001 is the core power module of ABB’s AC500 series PLC, designed to provide stable and reliable power support for industrial automation control systems. It is a key component that ensures the normal operation of the PLC core unit and peripheral modules. The following is its detailed product information:

Core Functions and Positioning

1. Core Power Supply of the System: Acting as the “power hub” for the AC500 series PLC, it is specially designed to provide a continuous and stable DC power supply to core components such as CPU modules, I/O modules, and communication modules. This ensures uninterrupted operation of key functions like system logic processing, data transmission, and device control, preventing system failures caused by power fluctuations.

2. High Compatibility and Expandability: Fully compatible with the entire modular component lineup of the AC500 series, it supports flexible expansion according to the scale of the control system. It can be seamlessly integrated with digital I/O modules, analog I/O modules, and special function modules, meeting the power supply requirements from small control cabinets to large distributed control systems.

3. Multiple Safety Protection Designs: Designed for complex industrial conditions, it features built-in overload protection, overvoltage protection, over-temperature protection, short-circuit protection, and reverse voltage protection mechanisms. This effectively guards against power anomalies, load faults, and wiring errors, preventing damage to the modules and the entire control system due to power issues.

4. Industrial-Grade Stable Operation: Utilizing industrial-grade high-quality components and electromagnetic interference (EMI) resistant designs, it complies with IEC industrial standards and the EN series of electromagnetic compatibility (EMC) standards. It can maintain long-term stable operation in harsh industrial environments, suitable for complex scenarios such as factory workshops and outdoor control cabinets.

Typical Application Areas:

1. Industrial Automation Production Lines: PLC control systems for production lines in automobile manufacturing, electronics assembly, mechanical processing, food packaging, etc., provide stable power supply to control modules for robots, conveyors, inspection equipment, actuators, and other devices, ensuring the continuity and accuracy of the production process.

2. Process Control Industry: Distributed Control Systems (DCS) in industries such as chemical, oil & gas, water treatment, power, and metallurgy supply power to field sensors, valve controllers, flow meters, and other equipment, ensuring the reliability of process parameter acquisition and execution of control commands.

3. Intelligent Buildings and Infrastructure: Centralized and stable power support for intelligent building systems, including air conditioning control, lighting systems, security monitoring, as well as automated control units in large infrastructure projects such as urban rail transit, airports, and ports, ensuring coordinated operation of equipment.

4. Energy Management Systems: Monitoring and control units for photovoltaic and wind power stations, and industrial power distribution systems provide stable power to power parameter acquisition modules, remote control modules, and other devices, ensuring continuous energy data monitoring and equipment control.

Product Advantages:

1. Strong Compatibility: Specifically designed for the AC500 series PLC, it can be seamlessly integrated without additional adaptation components, simplifying system setup and reducing equipment selection and commissioning costs.

2. Easy Installation and Maintenance: Standardized rail mounting and modular design facilitate on-site installation, disassembly, and future expansion; hot-swappable functionality (system support required) can reduce maintenance downtime and improve production efficiency.

3. Comprehensive Safety Protection: Multiple power protection mechanisms cover various common power supply risks, providing full-scale safety for the control system and reducing the likelihood of equipment damage and production interruptions.

4. Compliance with Industrial Standards: Adheres to IEC 61131-3 programming standards and industrial equipment design specifications, ensuring strong compatibility with global industrial automation systems and facilitating collaboration between devices from different brands.

Reviews

There are no reviews yet.