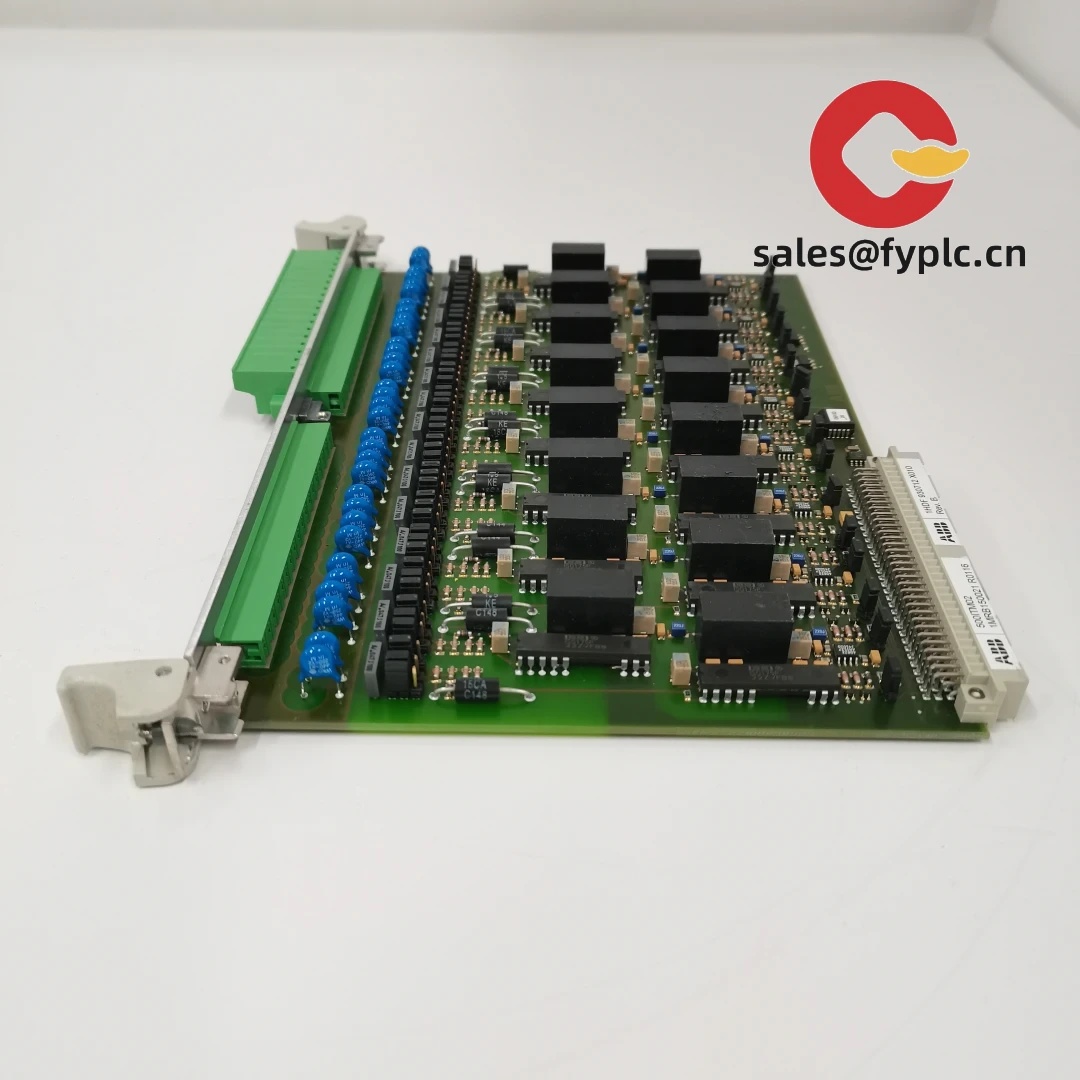

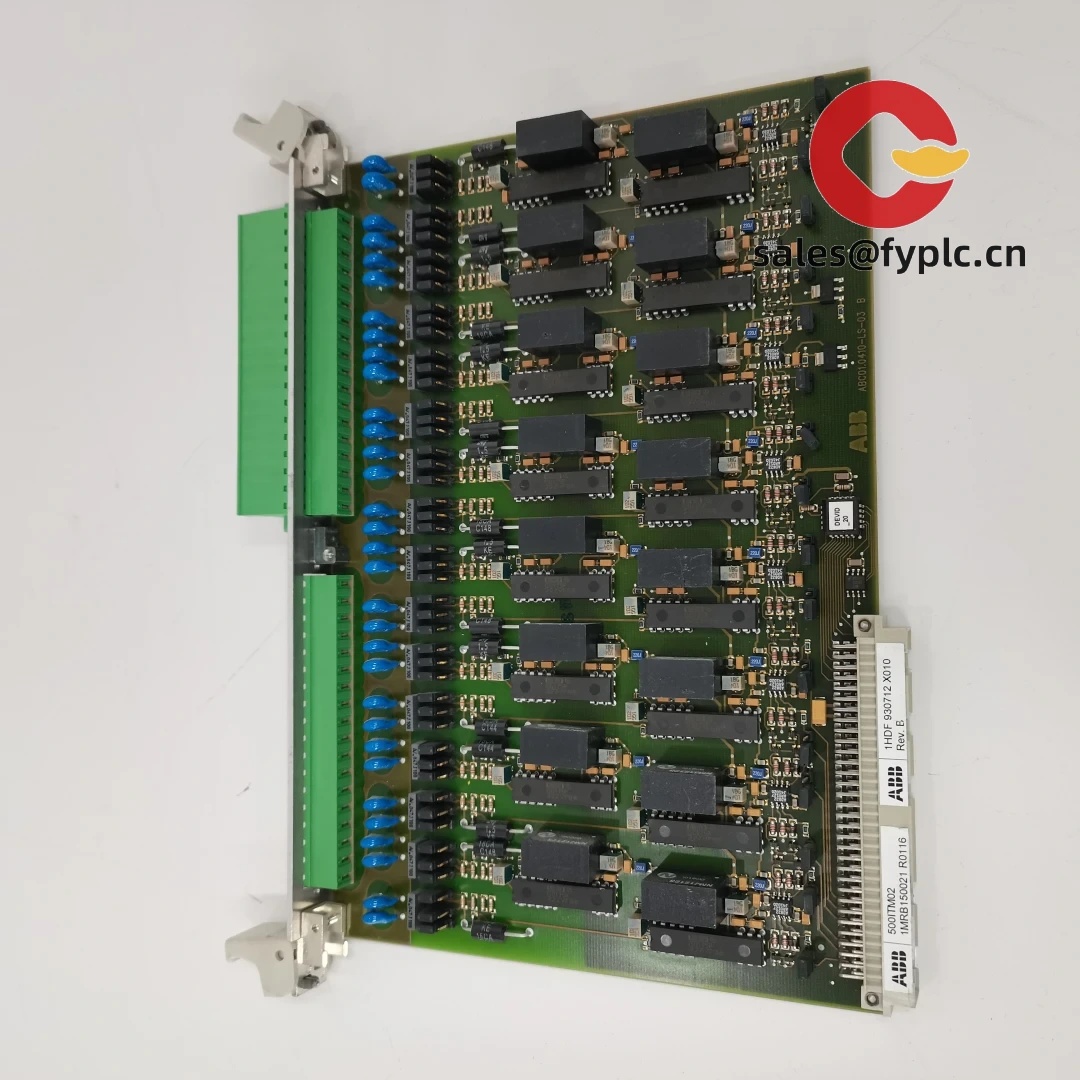

Description

500ITM02 1HDF930712X010 is an industrial communication interface controller launched by ABB, belonging to the AC 500 series automation product line. Its core role is as the ‘communication hub’ in industrial control systems, responsible for data exchange and network construction between different devices and protocols. It is a key component for small to large industrial automation systems. The following is a complete product information compiled based on official information and industry characteristics:

Core Positioning: As a dedicated communication module for the AC 500 series, its core function is to address the compatibility issues of multiple devices and protocols in industrial scenarios, enabling interconnection and interoperability among field sensors, actuators, PLCs, and host computers, and supporting distributed deployment and remote monitoring of the control system.

Core Functions

1. Multi-Protocol Compatibility and Conversion: Supports dual protocol systems to balance high-speed transmission and compatibility with traditional devices.

2. Ethernet Protocols: Ethernet/IP, Profinet, Modbus TCP, meeting high-speed data transmission and remote monitoring requirements.

3. Fieldbus Protocols: PROFIBUS DP, CANopen, RS485/RS232, compatible with traditional industrial equipment (such as legacy sensors and actuators); equipped with gateway functionality for data conversion between different protocols (e.g., interoperability between Modbus TCP and PROFIBUS DP).

4. Data Routing and Distributed Networking: Can serve as a master/slave to connect distributed I/O modules, sensors, actuators, and other devices to build complex industrial networks; supports directional data routing and forwarding to ensure low-latency transmission of critical control commands.

5. Real-Time Performance and Redundancy: Supports real-time data communication to meet the synchronicity requirements of industrial control; some versions feature dual network ports to provide communication redundancy, preventing system interruptions due to a single link failure.

6. High-Performance Data Processing: Built-in high-performance microprocessor enables complex protocol parsing, data preprocessing (filtering, packaging), and supports multitasking to ensure stability during high-volume data exchanges.

7. Fault Diagnosis and Status Feedback: Built-in self-diagnosis functions to monitor communication links and module operating status in real time; provides fault information feedback via LED indicators or host software (e.g., link disconnection, protocol mismatch) for quick troubleshooting.

Typical Application Scenarios

1. Process Industry: Distributed control systems in industries such as chemical, oil and gas, and water treatment, enabling remote data interaction between sensors (e.g., pressure, flow sensors), actuators (e.g., valves, pumps), and PLCs.

2. Manufacturing: Automotive assembly lines, food packaging production lines, and electronic component production lines, used for coordinated control and status monitoring of production line equipment (e.g., robotic arms, conveyors).

3. Energy Management: Distribution systems of photovoltaic power plants, wind farms, and substations, enabling communication networking of electrical equipment (e.g., inverters, circuit breakers) and uploading data to monitoring centers.

4. Building Automation: Centralized control of air conditioning, lighting, and security systems in large commercial buildings and industrial facilities, constructing intelligent building communication networks.

Reviews

There are no reviews yet.