Description

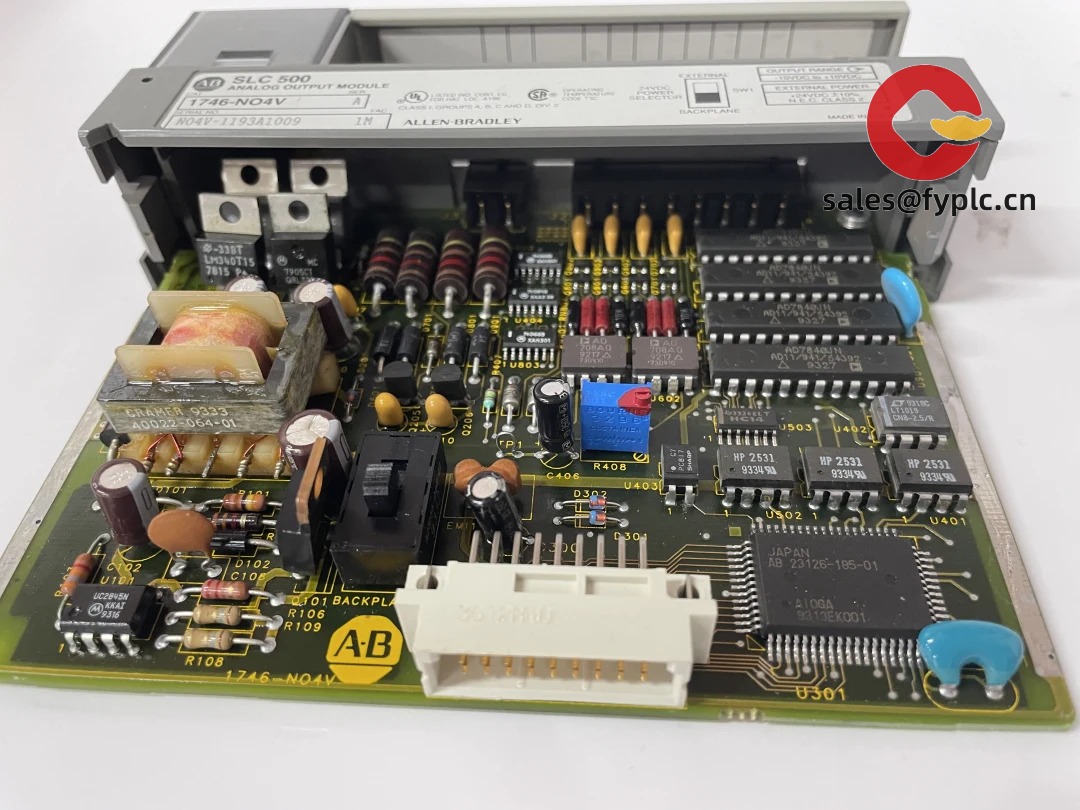

A-B 1746-NO4V/A (often shown as 1746-NO4VA) – 4‑channel analog voltage output for SLC 500 control

The Allen‑Bradley 1746‑NO4V/A is a 4‑channel analog voltage output module for the SLC 500 platform. It’s a straightforward way to generate control references—think 0…10 V or ±10 V signals—for drives, valve positioners, power supplies, or third‑party instruments. From my experience, teams pick this module when they want predictable scaling in RSLogix 500 and a drop‑in fit for existing 1746 chassis without fuss. You might notice that it’s voltage‑only; if you need current loops, the sister module is the -NO4I.

Our Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment terms: 50% advance payment, full payment for delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- 4 analog voltage outputs – Typical ranges include 0…10 V and ±10 V for broad device compatibility.

- 12‑bit resolution (per channel) – Clean, stable output steps suitable for speed reference and position control.

- Standard 1746 backplane – Powered and controlled by the SLC chassis; no external power brick or fieldbus adapters.

- Removable RTB wiring – Screw‑terminal block helps with neat panel wiring and quicker module swaps.

- Status indication – Front LED simplifies basic diagnostics during commissioning.

- Non‑isolated channels – Common‑referenced outputs; plan grounding and shields accordingly for noise‑sensitive loops.

Technical Specifications

| Brand / Model | Allen‑Bradley 1746‑NO4V/A (1746‑NO4VA), SLC 500 analog output |

| HS Code | 8538.90 (Parts for industrial control equipment) |

| Power Requirements | Supplied by 1746 backplane (5 VDC); no external supply required |

| Dimensions & Weight | Single‑slot 1746 I/O module; typical weight ~0.3–0.5 kg |

| Operating Temperature | 0 to +60 °C (typical for SLC 500 I/O) |

| Signal Input/Output Types | 4 analog voltage outputs; common voltage ranges 0…10 V and ±10 V; resolution 12‑bit; minimum load typically ≥2 kΩ |

| Communication Interfaces | 1746 backplane to SLC 5/0x controllers; configured in RSLogix 500 |

| Installation Method | Plug into 1746 chassis slot; field wiring via removable screw terminal block (RTB) |

Application Fields

- VFD speed references (0…10 V) and servo/positioner command signals on legacy SLC lines.

- Analog setpoints for temperature, pressure, or level controllers that accept voltage inputs.

- Power supplies and test stands where programmable voltage outputs simplify recipe changes.

- Retrofit projects in packaging, water/wastewater, and material handling—keep the 1746 chassis, modernize the field devices.

A maintenance tech in a bottling plant told us they swapped a faulty NO4V on a Saturday callout—downloaded the saved program, verified scaling, and the filler was back in spec before the next shift. That quick recovery is usually why teams keep a spare on the shelf.

Advantages & Value

- Drop‑in compatibility – Works across SLC 5/01…5/05 systems without special firmware tricks.

- Predictable engineering – Straightforward scaling and status bits in RSLogix 500 save troubleshooting time.

- Cost control – Keep your existing 1746 chassis and wiring; no need to re‑certify panels just to restore voltage outputs.

- Procurement certainty – Series A designation helps match installed base hardware for consistent performance.

Installation & Maintenance

- Panel & cabinet – Mount the 1746 chassis in a ventilated enclosure; follow NEC/IEC wiring and maintain analog cable separation from power.

- Wiring practices – Use shielded twisted pair for analog runs; land shields at a single point (controller end is typical) to avoid ground loops.

- Load and grounding – Verify the receiving device input impedance (≥2 kΩ is typical for this module). Tie analog commons carefully to plant ground.

- Configuration – Set the desired range in RSLogix 500 and confirm scaling (engineering units to raw/scale). Label channels and document ranges in the project notes.

- Routine care – Keep vents dust‑free, check terminal tightness, and back up program files after any range or scaling change. Firmware on the CPU, not the module, usually governs behavior.

- Safety – De‑energize the chassis before inserting or removing modules; verify analog outputs are disabled before wiring changes.

Quality & Certifications

- Typically complies with UL/cUL and CE for industrial control equipment; EMC performance depends on installation practices.

- Supplied units covered by our 365‑day warranty.

If you can share the SLC processor type and the devices you’re driving (drive make, input impedance, cable runs), I can double‑check range settings and suggest a clean wiring plan. One thing I appreciate is how quickly this module drops into a chassis and just works—provided the scaling and grounding are tidy.

Reviews

There are no reviews yet.