Description

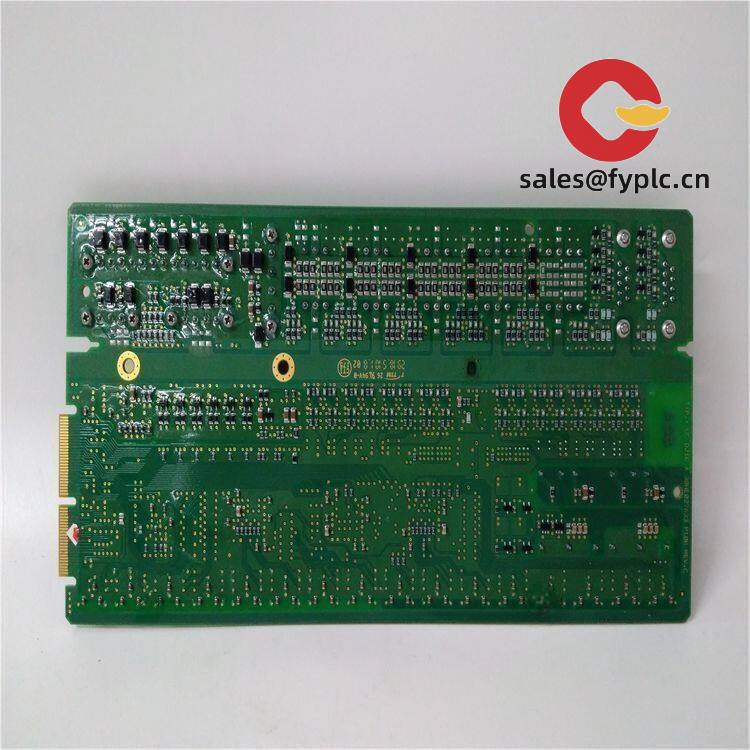

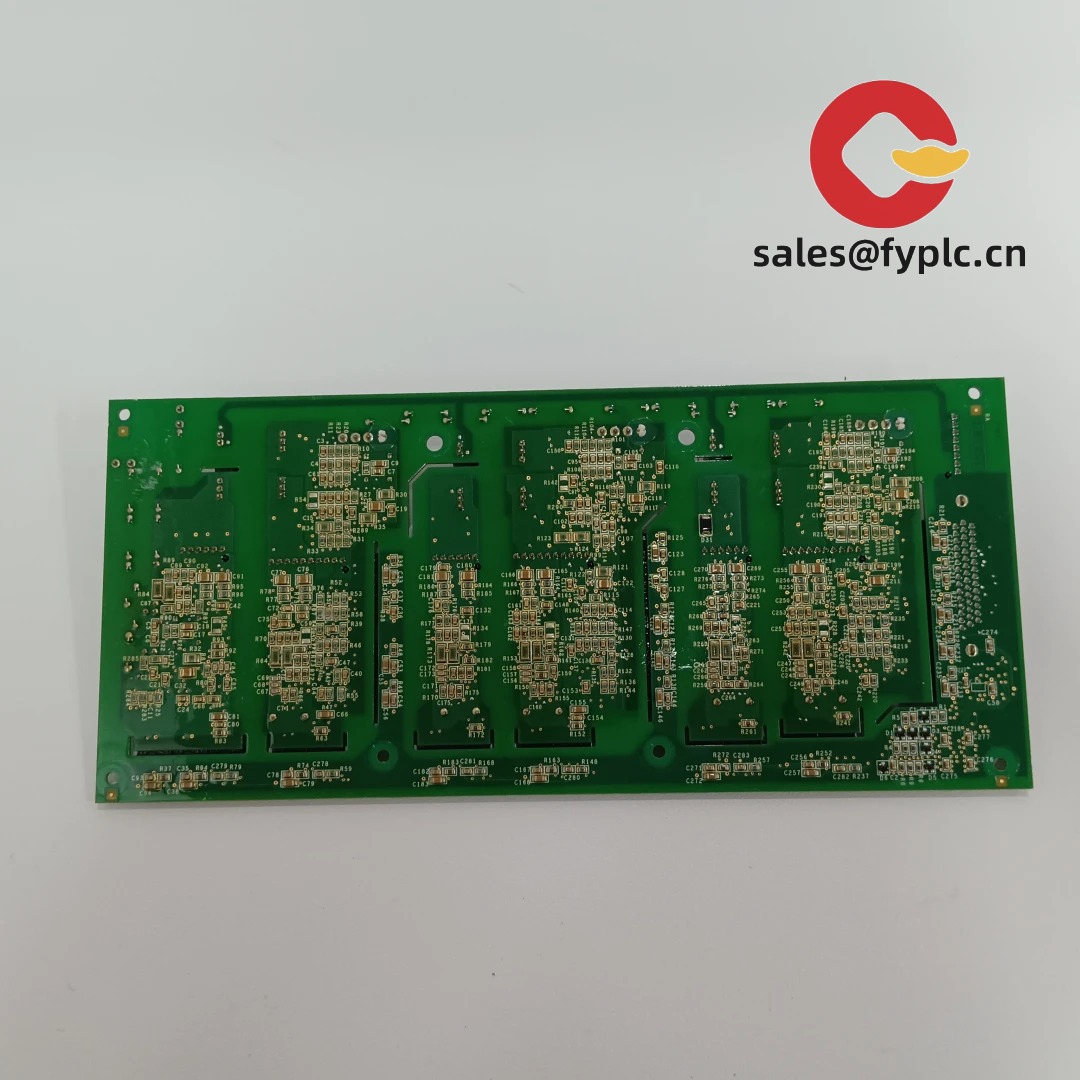

ABB 0504994880 — Compact, DIN-rail-mounted Analog Input Module for Industrial PLC Systems

Let’s cut to the chase: this isn’t a generic signal conditioner—it’s ABB’s dedicated 4-channel analog input module designed specifically for integration into their AC500 family of controllers (like the PM573 or PM583). From my experience supporting mid-sized OEMs and system integrators, it’s the kind of component that quietly prevents headaches—especially when you’re retrofitting legacy lines with tighter I/O requirements or scaling up modular packaging lines.

Key Features

- 4 universal analog inputs — Accepts voltage (±10 V), current (0–20 mA, 4–20 mA), and thermocouple (Type J/K) signals on the same channel—no hardware jumpers needed. One thing I appreciate is how the configuration happens entirely in Automation Builder, reducing wiring errors during commissioning.

- 16-bit resolution with 0.1% typical accuracy — Sufficient for most process monitoring tasks, like tracking pressure transducer outputs in HVAC control panels or verifying fill-level sensor consistency in beverage bottling lines.

- DIN-rail mountable (TS35/7.5 or TS35/15) — Fits cleanly alongside other AC500 modules without adapters. You might notice that its low profile (only 115 mm height) helps avoid airflow blockage in densely packed cabinets.

- Galvanic isolation (500 V AC between channels and bus) — Helps suppress ground loops—a real lifesaver when integrating third-party sensors powered from separate supplies (e.g., weigh scales in material handling systems).

- Integrated diagnostics & LED status per channel — Red/yellow/green LEDs show signal health, over-range, or open-circuit conditions. In many cases, this cuts troubleshooting time by half compared to digging through software logs first.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB 0504994880 |

| HS Code | 8537.10 — Boards, panels for industrial control systems |

| Power Requirements | Supplied via AC500 backplane (24 V DC ±15%, max. 120 mA) |

| Dimensions (W × H × D) | 25 × 115 × 125 mm (0.28 kg) |

| Operating Temperature | −25 °C to +60 °C (derating applies above +55 °C) |

| Signal Input Types | Voltage: ±10 V; Current: 0–20 mA / 4–20 mA; Thermocouple: J, K (cold-junction compensation built-in) |

| Communication Interface | Integrated into AC500 bus (no external comms required); configured via Automation Builder v3.0+ |

| Installation Method | DIN rail (TS35/7.5 or TS35/15); no tools needed for mounting or removal |

Application Fields

This module shows up where precision meets practicality: food & beverage production lines needing consistent analog feedback from flow meters and temperature probes; water treatment plants monitoring pH and turbidity sensors; and machine builders integrating hydraulic press position feedback without adding external signal conditioners. It’s less common in high-speed motion control (where encoder interfaces dominate), but shines in slower, measurement-heavy environments—like environmental chambers or HVAC BMS retrofits.

Advantages & Value

If you’re evaluating this against alternatives—say, a generic third-party analog input card—the value isn’t just in specs. Compatibility with ABB’s ecosystem means no driver development, no firmware mismatch risks, and seamless diagnostics inside the same engineering tool your team already uses. Reliability-wise, field data suggests MTBF exceeds 120,000 hours under normal cabinet conditions. And because it shares the same form factor and power budget as other AC500 I/O, you avoid cabinet redesign costs when expanding I/O later. Procurement teams also tend to like the predictability: no hidden licensing fees, no annual subscription for basic configuration.

Installation & Maintenance

Mount it in an IP20-rated control cabinet with ≥100 mm clearance above/below for convection cooling. Avoid direct sunlight or proximity to heat-generating devices like variable frequency drives—thermal stress seems to be the top cause of early drift in field reports. Wiring should use twisted-pair shielded cable for analog inputs, with shields grounded at the module end only. For maintenance: calibration isn’t user-serviceable (it’s factory-trimmed), but periodic verification using a certified source every 12–18 months is recommended. Firmware updates happen automatically during controller download—no manual intervention needed. Just keep the cabinet dust-free; accumulated dust on heatsinks has triggered thermal warnings in humid environments.

Quality & Certifications

Certified to CE (EMC & LVD), UL 508 (Industrial Control Equipment), RoHS 2011/65/EU, and conforms to IEC 61000-6-2/6-4. ABB backs it with a standard 365-day warranty—starting from delivery date, not invoice. In practice, most returns we’ve seen relate to incorrect configuration (e.g., misassigned thermocouple type), not hardware failure.

Our Order Placement Process & Guarantees:

• Warranty: 365 days from delivery

• Delivery: 1 week if in stock; ≤30 days maximum for custom or low-stock scenarios

• Payment: 50% advance, balance before shipment

• Shipping: FedEx, UPS, or DHL express — fully tracked, door-to-door

Reviews

There are no reviews yet.