Description

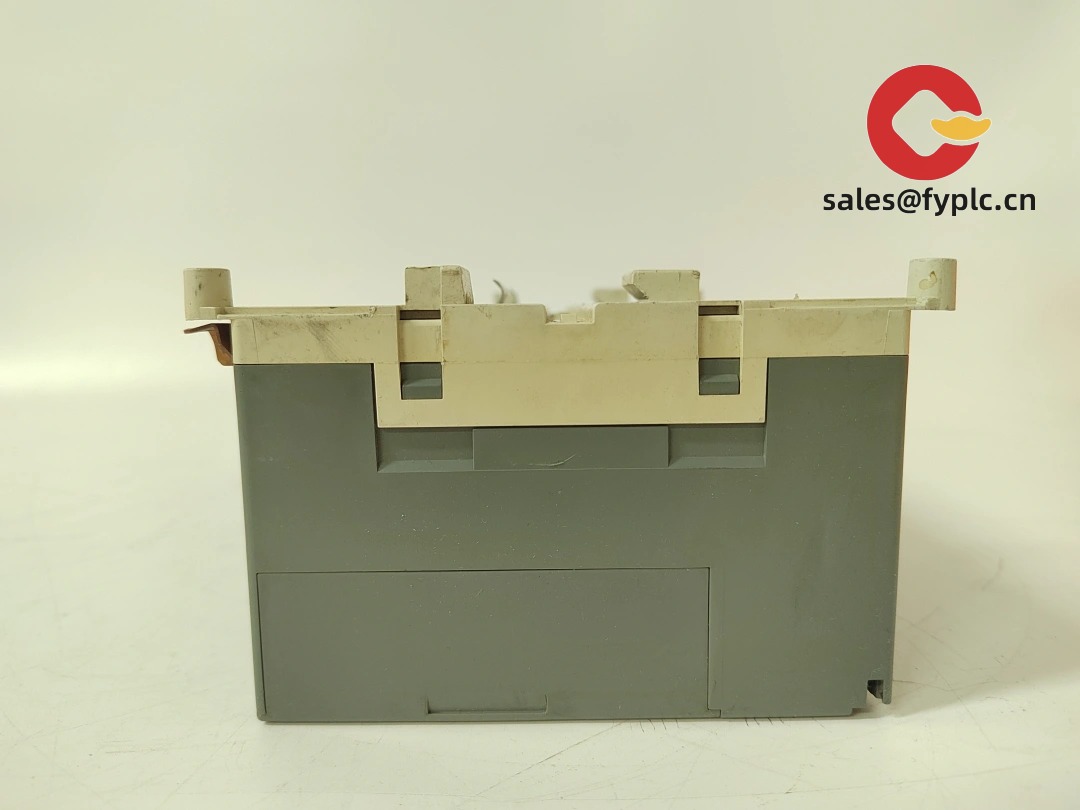

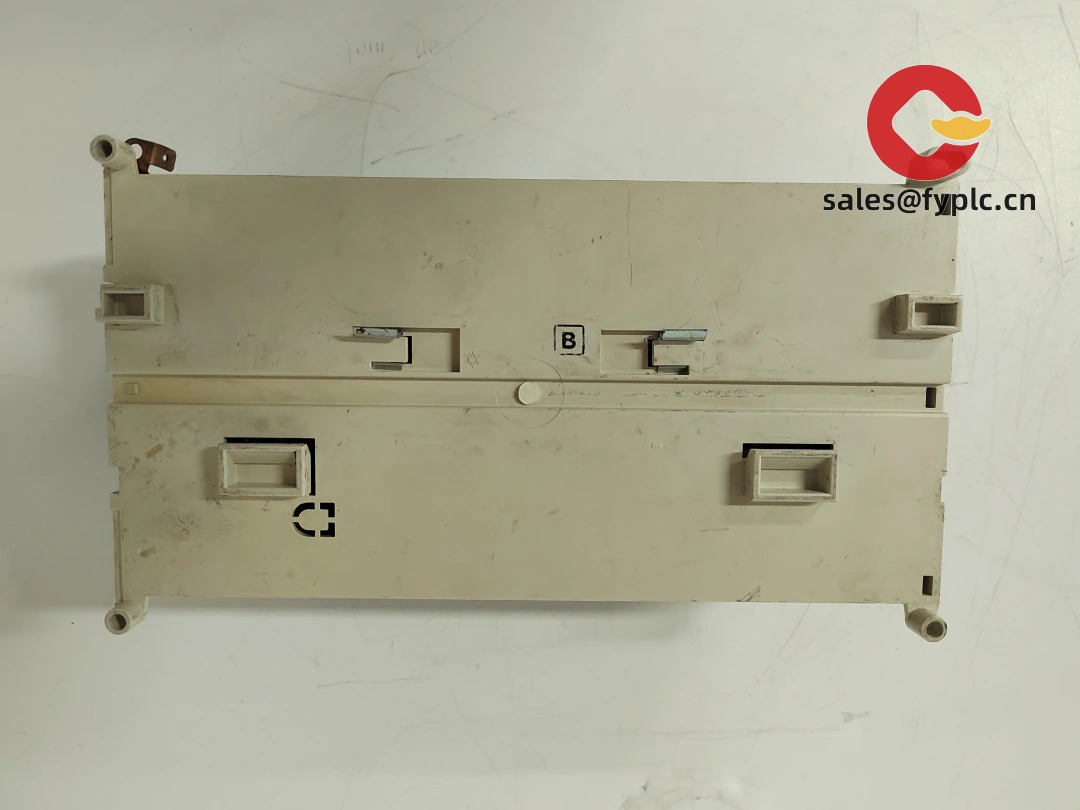

ABB 07KT98-H2 (GJR5253100R0278) – AC31 CPU Module for Stable Legacy Control and Fast Like‑for‑Like Swaps

ABB’s 07KT98‑H2, ordering code GJR5253100R0278, is an AC 31 family CPU used to keep legacy panels running reliably. From my experience, the H2 hardware variant is what sites install when they want a straightforward drop‑in brain replacement—same base, same field terminations, minimal fuss. You might notice it plugs into the standard AC 31 backplane and brings up expansion I/O without addressing changes, which is a lifesaver during short outage windows.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in‑stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

- Process: Confirm model and quantity → Proforma Invoice → Advance payment → Functional testing and packing → Final payment → Express shipment with tracking

Key Features

- Drop‑in AC 31 replacement – Fits the original AC 31 base; field wiring typically remains untouched.

- H2 hardware variant – In many cases offers improved stability and broader firmware support versus earlier revisions.

- Backplane I/O integration – Talks to AC 31 expansion I/O over the native bus; addressing usually stays consistent.

- Built‑in serial ports – Typically RS‑232/RS‑485 for programming and device links (S‑Bus/Modbus are common on this family).

- Service‑friendly diagnostics – Front LEDs and simple power‑up checks make outage work predictable.

Technical Specifications

| Brand / Model | ABB – 07KT98‑H2 (GJR5253100R0278), AC 31 CPU module |

| HS Code | 853710 (Programmable controller modules) |

| Power Requirements | 24 VDC via AC 31 base/backplane (typical) |

| Dimensions & Weight | Standard AC 31 footprint; approx. 0.4–0.6 kg module class |

| Operating Temperature | 0…55 °C cabinet ambient (typical for ABB PLC hardware) |

| Signal I/O Types | Backplane interface to AC 31 I/O bases; field signals remain on terminal bases |

| Communication Interfaces | RS‑232/RS‑485 serial for programming/devices; no integrated Ethernet on this class |

| Installation Method | DIN‑rail on AC 31 base; plugs into backplane with front‑accessible indicators |

Application Fields

Where this CPU typically fits best:

- Legacy AC 31 cabinets in water/wastewater, HVAC and utilities

- OEM/discrete machines where a like‑for‑like swap avoids a full migration

- Process skids with serial instruments and compact I/O counts

- Brownfield life‑extension projects across ABB installed bases

Advantages & Value

- Reliability: Like‑for‑like CPU swaps typically stabilize scan behavior and clear intermittent controller faults.

- Compatibility: Keeps the existing AC 31 base, I/O modules and serial links intact—no rewiring in most cases.

- Downtime savings: Faster restoration than a platform migration; less requalification effort.

- Support: We can power‑up test, verify port LEDs/activity, and share a brief functional report before shipment.

Installation & Maintenance

- Cabinet setup: Mount on the AC 31 base; keep ventilation paths clear and follow derating guidance.

- Power & grounding: Provide a clean 24 VDC source; bond cabinet ground; segregate noisy loads from logic wiring.

- Programming & backups: Maintain a current project backup; check clock/battery settings if your application uses them.

- Serial links: Match baud/parity; set RS‑485 termination/polarity; ground shields correctly to avoid loops.

- Handling & safety: Power down before removal/insertion; use ESD precautions when handling the CPU and connectors.

- Routine care: Quarterly dust removal, connector reseat checks, and periodic review of diagnostic/event logs.

Quality & Certifications

- Quality system: Manufactured under ISO 9001 processes (typical for ABB PLC hardware).

- Compliance: Suitable for CE/UL compliant industrial control panels; RoHS status may vary by production year.

- Warranty: 365‑day warranty from shipment date.

Share your AC 31 rack layout, I/O base types, firmware note (if known), and connected serial devices (protocol/baud). We’ll confirm 07KT98‑H2 (GJR5253100R0278) compatibility and prepare a concise functional test record before dispatch.

Reviews

There are no reviews yet.