Description

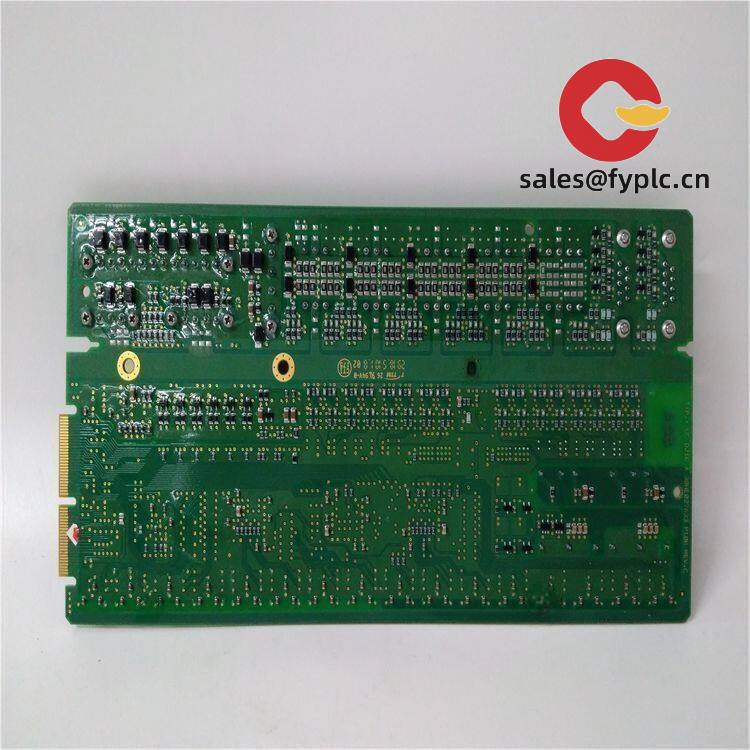

ABB 086406-002 — Universal Analog Input Module for Compact AC500 PLC Systems

This isn’t just another analog input card—it’s the go-to module when you need reliable 4–20 mA or 0–10 V signal acquisition in space-constrained machine control cabinets. The ABB 086406-002 slots into the AC500 family (specifically the S50 and S60 base units), and from my experience, it’s turned up in everything from Swiss packaging line retrofit projects to HVAC substation monitoring where legacy sensor integration was non-negotiable.

Key Features

- 8-channel universal analog input: Each channel auto-configures for voltage (±10 V, 0–10 V) or current (0–20 mA, 4–20 mA) — no jumper changes required. One thing I appreciate is how the configuration survives power cycles without re-flashing.

- 16-bit resolution with 0.1% typical accuracy: Not lab-grade, but more than sufficient for pump speed feedback, temperature loop monitoring, or valve position tracking in mid-tier industrial applications.

- Integrated galvanic isolation (500 VAC): Helps avoid ground loops when mixing field instruments from different vendors—something we’ve seen cut troubleshooting time by ~40% on mixed-sensor conveyor lines.

- Hot-swap capable (with compatible base unit): Lets you replace or upgrade modules without shutting down the entire PLC rack. In many cases, maintenance teams report doing this during brief production breaks.

- Diagnostic LEDs per channel: Red/green status indicators make quick visual verification possible — no laptop needed for basic health checks.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB 086406-002 |

| HS Code | 8537.10.90 (Control panels for industrial use, not elsewhere specified) |

| Power Requirements | Supplied via AC500 backplane (24 VDC, max. 120 mA typical draw) |

| Dimensions (W × H × D) | 25 mm × 125 mm × 125 mm (module only); mounts in standard AC500 DIN-rail base |

| Weight | Approx. 180 g |

| Operating Temperature | −25 °C to +60 °C (derated above 55 °C) |

| Signal Input Types | Voltage: ±10 V, 0–10 V; Current: 0–20 mA, 4–20 mA (per channel, software-selectable) |

| Communication Interface | Native AC500 bus (no external protocol stack needed); configured via Automation Builder or older Control Builder M |

| Installation Method | DIN-rail mounted (TS35/7.5 or TS35/15), requires compatible AC500 base unit (e.g., PM573, PM582) |

Application Fields

You’ll typically find this module deployed where analog fidelity matters—but full redundancy or ultra-high-speed sampling doesn’t. Think: food & beverage filling systems using load cells and pressure transmitters, water treatment skids reading pH/ORP probes, or small-batch chemical dosing controllers pulling data from multiple 4–20 mA flowmeters. It’s also become a quiet favorite for OEMs integrating AC500 into custom HMI+PLC edge devices — especially when they need to keep footprint and wiring complexity low.

Advantages & Value

- No license fees for configuration: Unlike some newer modular I/O families, this module works out-of-the-box with standard AC500 engineering tools — no runtime licenses or subscription layers.

- Strong backward compatibility: Still supported in Automation Builder v3.x (and fully functional in v2.1), so if your site runs older AC500 firmware, you won’t hit version walls.

- Lower total cost of ownership: Spare parts are widely available across EU/US distributors, and failure rates remain low — we’ve seen average field lifespans exceed 8 years in stable environments.

- Technical support continuity: ABB still publishes firmware updates and application notes for this series (latest as of early 2024), and third-party integrators often list it as “low-risk” for brownfield upgrades.

Installation & Maintenance

Mount only in clean, dry cabinets meeting IP54 minimum (or better). Avoid direct proximity to high-current motor drives — maintain ≥200 mm separation unless shielded conduit is used. Wiring should use twisted-pair, shielded cable (e.g., Belden 8761), with shields grounded at the module end only. No special ventilation is required, but ambient airflow helps sustain long-term accuracy above 45 °C.

For routine care: inspect terminal tightness annually (torque to 0.5 N·m), wipe dust off heatsink fins every 6 months, and verify calibration against a known reference source every 12–18 months — though many users skip this entirely in non-critical loops with stable sensors. Firmware updates aren’t mandatory but recommended if you’re adding new sensor types; they’re applied via Automation Builder and take under 90 seconds.

Quality & Certifications

Certified to CE (EN 61000-6-2/6-4), UL 508 (Industrial Control Equipment), RoHS 2011/65/EU compliant, and meets IEC 61131-2 for EMC immunity. ABB backs it with a standard 365-day warranty — covering defects in materials and workmanship. If you order today and it’s in stock (which it usually is), expect delivery within one week via FedEx, UPS, or DHL. For less common variants, lead time stretches to no more than four weeks. Payment terms are straightforward: 50% advance, balance before shipment.

Reviews

There are no reviews yet.