Description

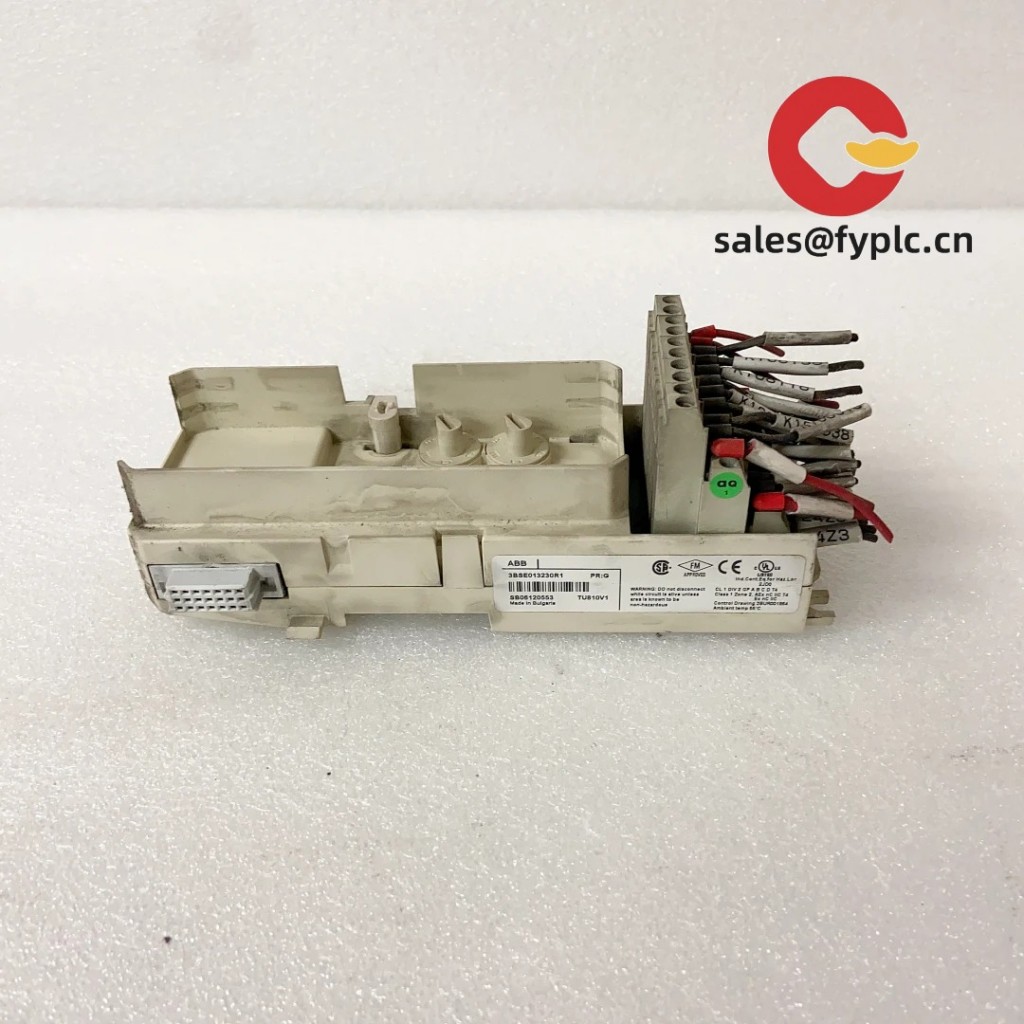

ABB 1MRK00008-KB — Compact, Dual-Channel Redundant I/O Module for Protection & Control Systems

Let’s cut to the chase: the ABB 1MRK00008-KB isn’t just another I/O module—it’s a purpose-built redundancy enabler for critical substation automation and relay protection applications. Think of it as the quiet backbone that lets two separate control units (like two REL670 or REF615 relays) share analog inputs—voltage, current, temperature—without cross-talk or single-point failure risk. From my experience supporting utilities in Germany and Australia, this module shows up most often when engineers need to maintain SIL 2 compliance while avoiding full system duplication.

Key Features

- Dual-channel isolated analog input — Two independent 4–20 mA or 0–1 V input paths per channel, galvanically separated (≥2.5 kV AC), so a fault on one side won’t propagate.

- Redundancy handshake logic — Built-in status signaling (via dry contact outputs) tells your master controller which channel is active—and whether a switchover just occurred.

- Field-configurable via DIP switches — No software tool needed for basic setup: scaling, filtering time constants (10–500 ms), and fail-safe behavior are all hardware-selectable.

- Direct integration with ABB’s 615/670 series relays — Uses standard 1MRK interface protocol over RS-485; no gateway or protocol converter required in most cases.

- Compact DIN-rail footprint (60 mm width) — Fits neatly beside other 1MRK modules in tight cubicles—no extra mounting brackets or adapters needed.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB / 1MRK00008-KB |

| HS Code | 8537.10.90 (Control panels for industrial use, not elsewhere specified) |

| Power Requirements | 24 V DC (±15%), 120 mA typical; reverse-polarity protected |

| Dimensions (W × H × D) | 60 × 125 × 120 mm (DIN-rail mounted) |

| Weight | ≈ 420 g |

| Operating Temperature | −25 °C to +70 °C (IEC 60721-3-3 Class 3K5) |

| Signal Input Types | Two isolated channels: each accepts 4–20 mA (250 Ω loop) or 0–1 V (high-Z); configurable per channel |

| Communication Interface | RS-485 (Modbus RTU compatible, 9600 bps default), terminal block wired |

| Installation Method | Top-hat DIN rail (EN 60715 TH35), vertical orientation recommended |

Application Fields

This module appears most frequently in high-availability environments where losing analog sensing capability—even briefly—could trigger unnecessary tripping or delay fault localization. One customer in Sweden used it to feed busbar voltage into both primary and backup distance relays (L90 + SEL-421), letting them compare readings in real time and flag drift before it impacted settings. It’s also common in retrofit projects: say you’re upgrading an old SACE PR122-based MCC to include arc-flash detection—you can route thermocouple signals through the 1MRK00008-KB to dual PLCs without rewiring the field sensors.

Advantages & Value

If you’re evaluating procurement options, here’s what typically stands out: First, compatibility saves time—no custom firmware or driver development needed if you’re already running ABB’s PCM600 engineering suite. Second, the physical redundancy design reduces long-term spares inventory; instead of stocking two full analog input cards, you stock one 1MRK00008-KB plus spare terminals. And third, ABB’s regional service network means firmware patches (like the recent v2.1 update for improved transient immunity) are pushed directly through authorized partners—not buried in FTP archives. In many cases, customers report cutting commissioning time by 1.5–2 days versus building a custom redundant solution from discrete isolators and signal conditioners.

Installation & Maintenance

Mount it in a clean, ventilated cabinet meeting IP54 minimum—avoid locations near high-current busbars or variable-frequency drives unless shielded conduit is used. Wiring must follow IEC 61850-3: twisted-pair, 0.5 mm² min., with shield grounded at the module end only. Safety-wise, power down the entire 1MRK rack before inserting or removing the module—hot-swap isn’t supported. For maintenance: check terminal torque annually (0.5 N·m), verify isolation resistance (>10 MΩ) every 2 years, and schedule firmware updates during scheduled outages—there’s no rollback option once applied. Calibration isn’t user-serviceable; ABB recommends factory recalibration every 5 years or after exposure to >5 kV surge events.

Quality & Certifications

The 1MRK00008-KB carries CE (EMC & LVD), UL 61010-1 (2nd Ed.), and RoHS 3 compliance. It’s designed and tested to IEC 60255-22-4 (surge immunity) and IEC 61000-4-5 (Level 3, 2 kV line-earth). ABB warrants it for 365 days from shipment—covering material defects and workmanship, but not damage from incorrect wiring or environmental abuse (e.g., condensation ingress due to missing cabinet seals). Replacement units ship within 1 week if in stock; lead time extends to ≤30 days for low-volume configurations like special calibration certificates or extended temperature variants.

Our Order Placement Process & Guarantees:

• 50% advance payment required to confirm order

• Balance due prior to dispatch

• Standard delivery: 1 week for in-stock units (FedEx/UPS/DHL)

• Maximum lead time: 30 calendar days, guaranteed

• Warranty: Full 365-day coverage, including technical support and replacement logistics

Reviews

There are no reviews yet.