Description

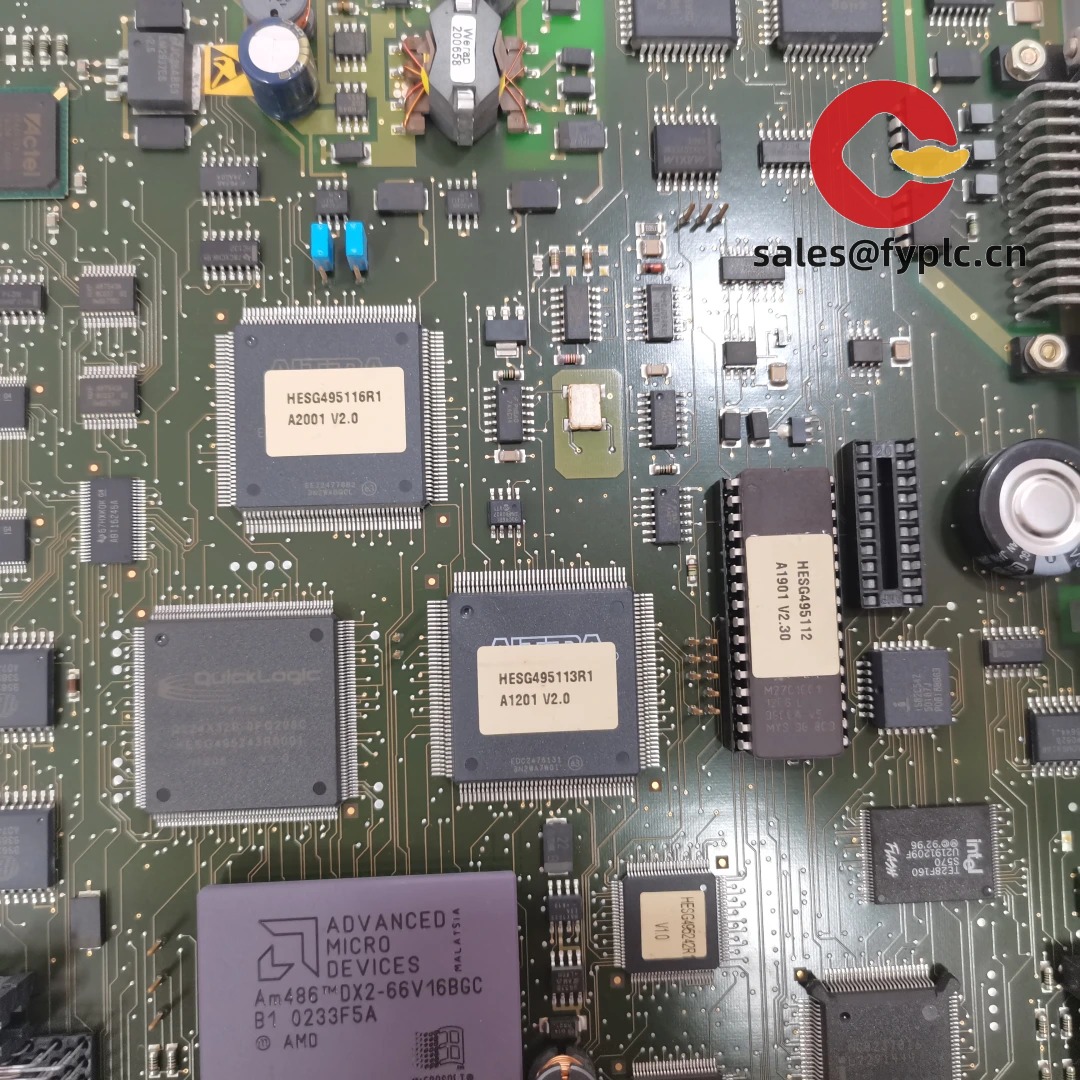

ABB 216VC62A HESG324442R112/F – Industrial Control Relay Module for Reliable Process Automation

If you’re working on maintaining or upgrading a legacy ABB automation setup—particularly in power distribution or turbine control systems—you’ve likely come across the 216VC62A. It’s not flashy, but it’s built to keep critical processes running without drama. From my experience, this module tends to show up in older Advant OCS and Symphony systems where reliability under continuous load matters more than cutting-edge features.

One thing I appreciate is how straightforward it is: no complex configuration, just solid-state switching with isolation that holds up well in electrically noisy environments. You might notice that newer systems are moving toward programmable logic solutions, but in many cases, replacing these relays outright isn’t cost-effective—especially when they’re still performing as intended after 10+ years.

Key Features

- Relay Output Module: Provides isolated relay outputs for commanding breakers, alarms, or auxiliary equipment—typically used in safety interlocks and status indication circuits.

- Plug-in Design: Fits directly into ABB HESG3xxx series racks, making replacement quick and reducing downtime during maintenance cycles.

- Galvanic Isolation: Input/output separation helps prevent ground loops and protects sensitive upstream controllers from voltage spikes.

- LED Status Indicators: Clear visual feedback on channel activity and power status—useful when troubleshooting in dimly lit control cabinets.

- Backward Compatibility: Works seamlessly within existing ABB Symphony and Advant OCS architectures, which seems to be a key reason customers still source this model today.

Technical Specifications

| Brand / Model | ABB / 216VC62A (HESG324442R112/F) |

| HS Code | 85371090 – Control panels for industrial automation systems |

| Power Requirements | Supplied via backplane; typically operates at 24 VDC control voltage on input side |

| Dimensions & Weight | Approx. 120 x 80 x 50 mm; ~300 g (standard plug-in module size) |

| Operating Temperature | 0°C to +60°C (industrial-grade tolerance for cabinet-mounted use) |

| Signal Input/Output Types | Digital inputs (dry contact), Relay dry contact outputs (SPDT per channel) |

| Communication Interfaces | None – purely I/O function; communicates via backplane signaling |

| Installation Method | DIN rail mount using compatible ABB rack (e.g., HESG300xxx series) |

Application Fields

This module typically appears in aging but operational installations like thermal power plants, water treatment facilities, and oil & gas compression stations. It’s commonly found handling discrete output tasks such as trip signal distribution, alarm annunciation, and motor starter enable circuits. While not suited for high-speed data logging or modern fieldbus integration, it remains a dependable choice where simple, fail-safe relay action is required.

Advantages & Value

Procurement teams often prioritize availability and compatibility over new functionality when dealing with legacy systems. The 216VC62A delivers value by avoiding system-wide retrofits—keeping downtime low and operational continuity high. In most cases, swapping in a tested unit takes less than 15 minutes if the rack is already configured. There’s also peace of mind knowing it doesn’t require firmware updates or software tools, reducing dependency on specialized engineers.

Installation & Maintenance

Mounting requires a standard ABB-compatible I/O rack with proper grounding. Make sure the cabinet meets IP54 standards, especially in humid environments. Ventilation should allow for natural convection cooling—don’t stack modules too tightly. Before insertion, verify power is off to avoid backplane arcing. Once installed, periodic checks should include cleaning dust from connectors and confirming LED indicators respond correctly during test sequences. Since it has no user-serviceable parts, physical inspection and functional testing are usually sufficient.

Quality & Certifications

The unit carries CE marking and complies with relevant EU directives for industrial equipment. It was originally manufactured under ISO 9001 quality standards, and RoHS compliance applies depending on production date (post-2006 units). Each replacement module we supply undergoes basic continuity and insulation resistance testing before shipment. Warranty is 365 days from delivery—covers defects in materials and workmanship under normal operating conditions.

Delivery typically takes one week if in stock; otherwise, no longer than four weeks. We ship via FedEx, UPS, or DHL. Payment terms are 50% upfront, balance due before dispatch. Keep in mind that while exact replacements are available, extended lead times can occur due to obsolescence—so planning ahead helps avoid unplanned outages.

Reviews

There are no reviews yet.