Description

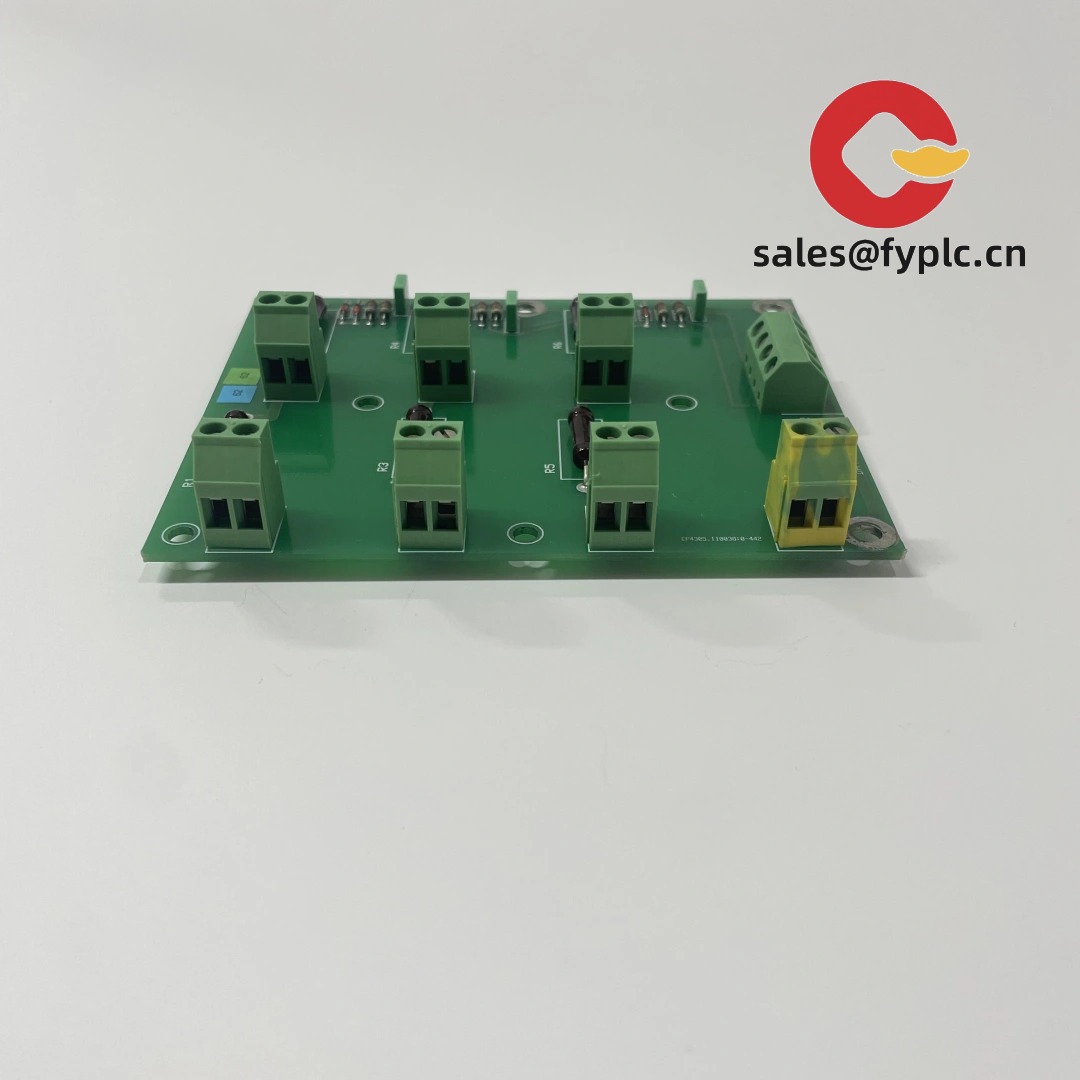

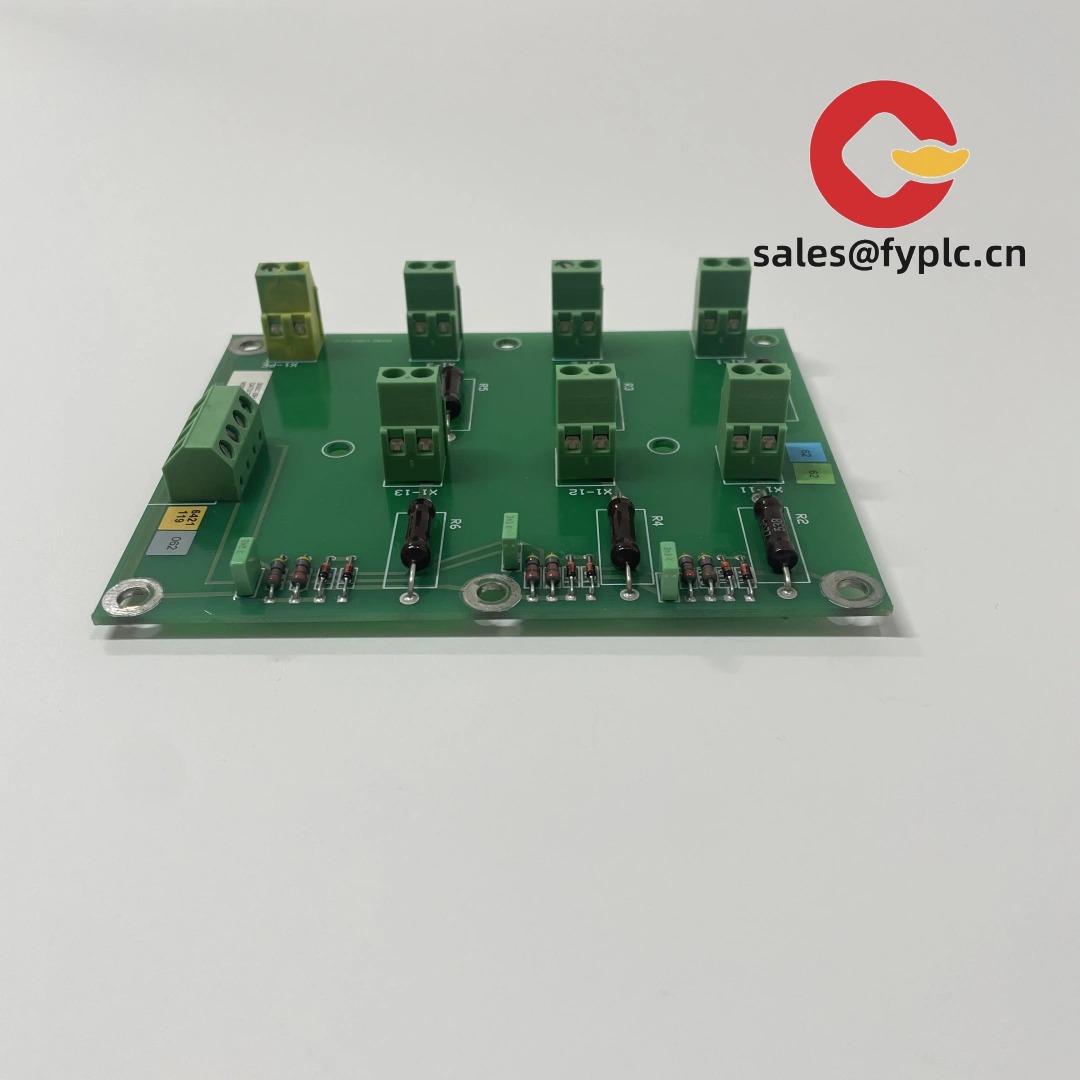

ABB 3ASC25H215E-DATX131 – DATX131 data/communication board for Advant/800xA legacy DCS

The ABB 3ASC25H215E-DATX131 (often referenced simply as DATX131) is a board-level module used in ABB Advant/800xA-based control systems to handle high-reliability data exchange on the system backplane or designated fieldbus segment. From my experience, this part is typically ordered as a form-fit-function replacement to stabilize legacy units, especially when a plant wants to extend service life without rushing a platform migration.

You might notice that it slots straight into the designated rack position and works with the existing controller configuration, which saves a lot of commissioning time in many cases.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week for in‑stock units; no more than one month at the latest

- Payment terms: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

- Test & verification: each unit is visually inspected and powered for basic functional checks before dispatch

Key Features

- Form-fit replacement for ABB legacy racks – Designed to drop into the appropriate Advant/800xA rack position with no mechanical modifications.

- Backplane/fieldbus data handling – Serves as a data transceiver/interface, ensuring stable controller communications in continuous process environments.

- Stable operation under industrial temperatures – Typically engineered for 0–55 °C cabinet conditions common in process plants.

- Service-friendly design – Board-level module that can be cold‑swapped during scheduled downtime; straightforward seating in card guides.

- Compatible with existing configuration – In many cases, no logic application changes are needed if you’re replacing like‑for‑like.

Technical Specifications

| Brand / Model | ABB 3ASC25H215E-DATX131 (DATX131) |

| HS Code | 8538.90 – Parts suitable for apparatus of heading 8537 (industrial control assemblies) |

| Power Requirements | Backplane supplied; nominal 5 VDC; typical consumption < 5 W |

| Operating Temperature | 0 to 55 °C (32 to 131 °F), typical control cabinet conditions |

| Signal I/O Types | Data/communication interface for controller/backplane or designated fieldbus segment (logic‑level on backplane) |

| Communication Interfaces | System backplane interconnect; supports ABB Advant/800xA legacy communication topology |

| Installation Method | Rack-mounted PCB; slides into card guides and secures with front retaining screw; cold-swap recommended |

| Dimensions & Weight | Approx. 230 × 100 × 20 mm; ~0.25 kg |

Application Fields

Plants running ABB Advant/800xA legacy architectures typically use the DATX131 as part of the controller communications path. It’s common in:

- Power generation (steam, combined cycle, and balance‑of‑plant subsystems)

- Pulp & paper (stock prep, dryer sections, and machine control)

- Metals & mining (drive lines, annealing, and process interlocks)

- Oil & gas / petrochem (compressor control, utility units, flare and safety‑related auxiliaries)

- Water & wastewater (filter beds, blowers, pump stations with legacy controllers)

A maintenance manager told us this board “bought us another shutdown cycle,” because it restored a noisy comms segment that was throwing intermittent controller diagnostics. That seems to be a typical scenario when plants are extending asset life while planning migrations.

Advantages & Value

- Reliability – OEM-spec hardware keeps controller communication deterministic and stable.

- Compatibility – Maintains existing Advant/800xA configurations, which typically shortens outage windows.

- Cost control – A targeted board replacement is often far less than a full I/O migration.

- Support – We coordinate pre‑shipment checks and can share handling notes so your technicians install it right the first time.

Installation & Maintenance

- Cabinet environment: Follow IEC/UL cabinet practices; ensure ventilation and keep ambient within 0–55 °C. Avoid vibration and conductive dust.

- Wiring & seating: De‑energize the rack (cold swap). Observe ESD precautions. Slide the board along card guides, seat fully into the backplane connector, and secure the front screw.

- Grounding: Maintain proper cabinet grounding and shield termination to minimize communication noise.

- Routine care: Inspect connectors during outages, clean with ESD‑safe methods, and check for oxidation on edge contacts.

- Firmware/configuration: If applicable to your system revision, verify module recognition in the controller diagnostics after power‑up; keep backups of configuration files.

Quality & Certifications

- Manufacturer quality aligned with ISO 9001 production systems

- CE marking applicable to the assembled control system

- UL/CSA compliance typically at the system/cabinet level where the module is installed

- 365‑day warranty coverage for repair/replace

Recommended Supporting Components

To keep spares aligned, plants usually pair the DATX131 with:

- Matching system rack/backplane for the relevant Advant/800xA node

- Controller CPU and power supply spares for the same rack generation

- Shielded fieldbus/communication cables and labeled terminal accessories

If you share the exact rack type and controller node, I can confirm board position, backplane pinout expectations, and any revision‑level notes before shipment.

Reviews

There are no reviews yet.