Description

ABB 3ASC25H216A-DATX132 – Drive Control Board for Reliable Internal Control and Feedback

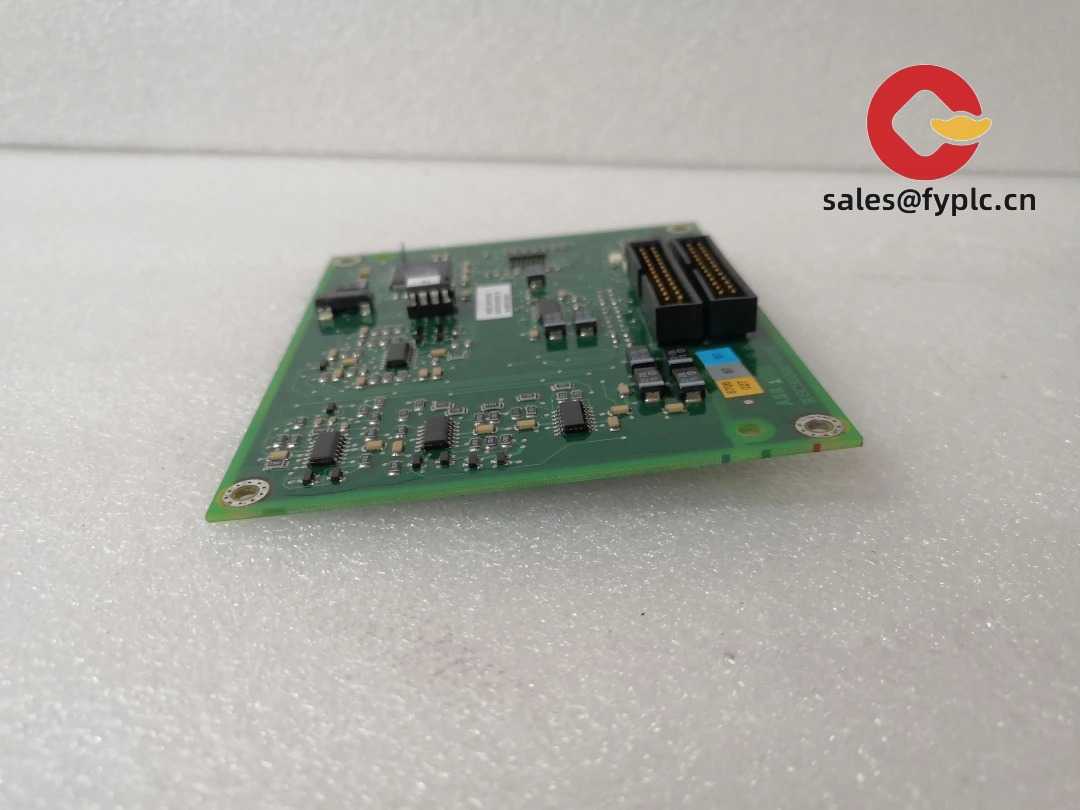

The ABB 3ASC25H216A-DATX132 is a genuine drive control board designed for use inside ABB industrial drives. In many cases it serves as an internal control/feedback interface PCB, bridging low‑voltage signals between the power section and the drive’s control logic. One thing I appreciate is how the DATX132 revision helps ensure firmware and hardware compatibility within specific ABB drive frames, which typically shortens swap time on site. If you’re maintaining ABB drives on a production line, this board tends to be a straightforward drop-in when the revision matches your installed set.

Our Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

- Pre‑ship testing: Each board is powered and function-checked before packing

- Compatibility support: We verify DATX132 fit against your drive tag to avoid mismatch

Key Features

- DATX132 hardware/firmware revision – Aligns with specific ABB drive configurations for stable operation.

- Drop‑in service replacement – Typically installs inside the drive chassis with existing standoffs and harnesses.

- Robust industrial design – Built for cabinet environments with electrical noise and continuous duty.

- Factory traceability – Clear labeling for version control and maintenance record keeping.

- Reduced downtime – Quick changeover in most cases; no field wiring changes required.

Technical Specifications

| Brand / Model | ABB 3ASC25H216A-DATX132 |

| HS Code | 853890 (Parts for industrial electrical control apparatus) |

| Power Requirements | Supplied by host drive low‑voltage rail (typically 24 VDC; low power) |

| Operating Temperature | Typically 0 to +55 °C (inside an enclosed control cabinet) |

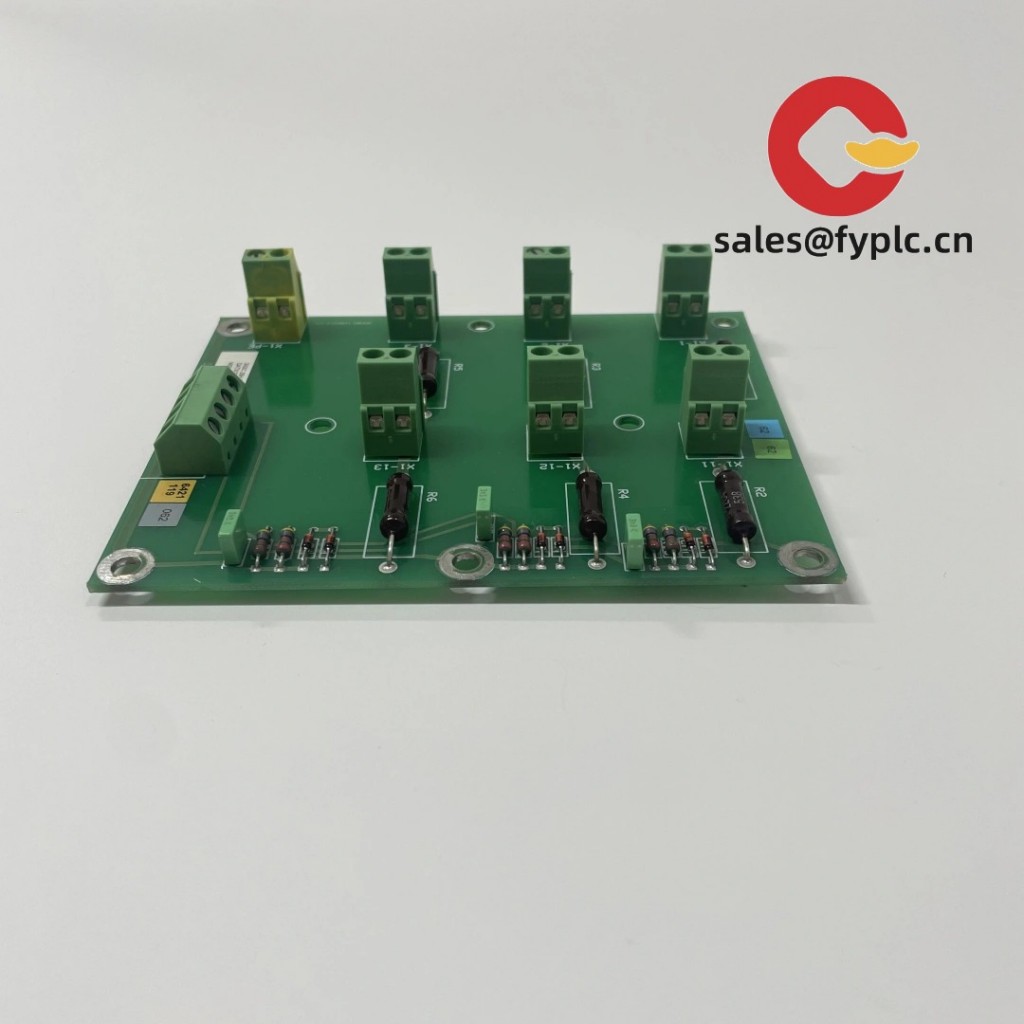

| Signal I/O Types | Internal low‑voltage control/feedback via board headers; no direct field I/O terminals |

| Communication Interfaces | Proprietary internal bus/backplane interfaces used within ABB drives (not a standalone fieldbus module) |

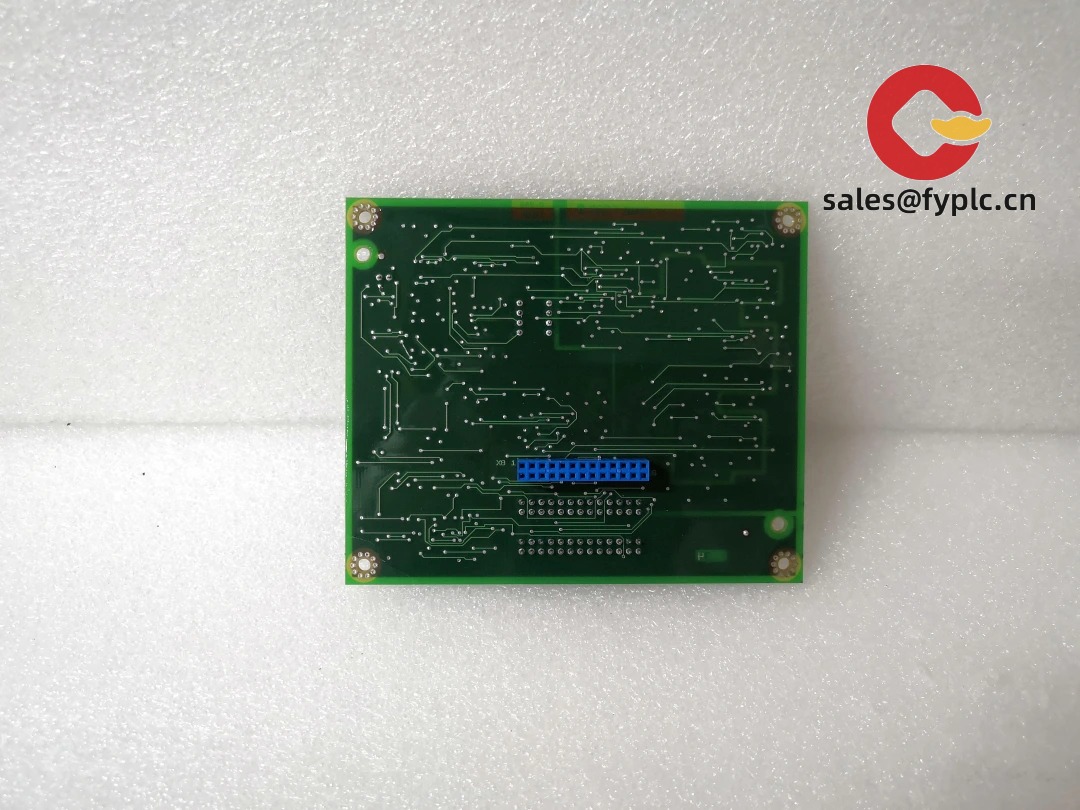

| Installation Method | Plug‑in PCB mounted inside the drive; secured with standoffs and connected via ribbon/loom cables |

| Form Factor | Board‑level module; compact footprint suitable for ABB drive chassis |

Application Fields

From my experience, this board shows up most often in maintenance programs for ABB AC/DC drives across heavy industries. Typical use cases include:

- Metals (rolling mills, continuous casting lines)

- Pulp & Paper (winders, coaters, press sections)

- Mining and cement (crushers, conveyors, kiln drives)

- Marine and port cranes (hoist/travel drives)

- Chemicals and refining (pump and compressor drives)

Advantages & Value

- Reliability first – Genuine ABB parts typically offer predictable behavior under electrical noise and thermal load.

- Compatibility assurance – We cross‑check your drive tag and firmware so the DATX132 revision matches your installed base.

- Cost and time savings – A direct replacement board means minimal re‑engineering; usually no field wiring changes.

- Documented testing – Functional test report provided on request, which seems to be appreciated by audit teams.

- Packaging and handling – ESD‑safe, shock‑resistant packing to reduce transit risk.

Installation & Maintenance

- Cabinet environment – Install in a clean, dry cabinet with adequate ventilation; keep ambient typically within 0…55 °C.

- Power isolation – Lockout/tagout the drive; wait for DC bus discharge. Disconnect 24 VDC auxiliaries before handling.

- ESD precautions – Use a grounded wrist strap and ESD mat; handle the board by edges only.

- Connector care – Inspect headers and ribbon cables for bent pins or oxidation; reseat firmly but avoid over‑tightening standoffs.

- Firmware alignment – Keep the DATX132 revision consistent with the host drive’s control firmware; update only with OEM‑approved tools.

- Routine upkeep – Light dust removal with dry, oil‑free air; periodic visual checks for hot spots or swollen capacitors.

Quality & Certifications

- Manufacturer quality system: ISO 9001

- Conformity: CE; RoHS (typical for ABB control PCBs)

- Safety: Designed for use in certified ABB drive systems; UL recognition may apply at system level

- Warranty: 365 days from shipment

What other customers said

“We swapped a failed 3ASC25H216A with the DATX132 revision over a lunch break. No field wiring changes, and the winder was back to spec within the hour.” — Maintenance Supervisor, paper mill

You might notice that lead times can vary by revision; if your production window is tight, share a photo of your drive nameplate and existing board label and we’ll validate compatibility before you place the order.

Reviews

There are no reviews yet.