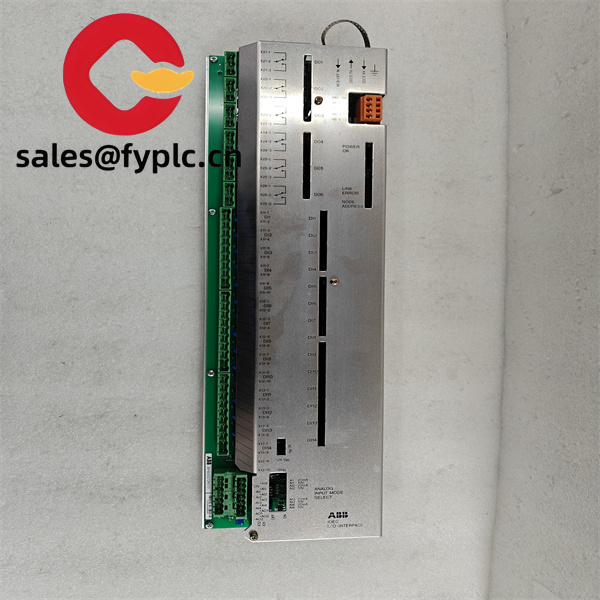

ABB 3BHB003041R0101 UFC719AE01 Control Board Analog Motion Input Module

| Model Number | 3BHB003041R0101 |

| Brand | ABB |

| Type | I/O Control Board (IOEC) |

| Input Voltage | Typically operates within a specific voltage range suitable for industrial applications, though the exact value might vary depending on the system it’s integrated with. For example, it could be designed to handle common industrial voltages like 24V DC or 110 – 240V AC with appropriate tolerances |

Categories: ABB

Need help?

Email: sales@fyplc.cn

Tel/WhatsApp: +86 173 5088 0093

Description

ABB 3BHB003041R0101 UFC719AE01 Control Board Analog Motion Input Module

Introduction & Core Purpose

In the complex world of industrial automation, ABB’s 3BHB003041R0101 UFC719AE01 emerges as a vital component. Engineered by the globally recognized ABB, this module serves as an I/O control board, playing a fundamental role in the seamless operation of industrial systems.

The 3BHB003041R0101 UFC719AE01 is specifically designed to support a wide range of industrial control setups. It is commonly integrated into industrial automation systems, where it acts as a bridge between various components. For example, in manufacturing plants, it can connect sensors that detect product quality or machinery status to the central control unit. By relaying real – time data from these sensors, it enables operators to make informed decisions promptly. In process control industries such as chemical plants, the module helps in controlling the flow of materials and regulating process parameters. It fits neatly into systems like ABB’s own Advant or similar automation control frameworks, ensuring smooth communication and coordinated control across different parts of the industrial operation.

Technical Highlights Table

| Label | Specification |

|---|---|

| Model Number | 3BHB003041R0101 |

| Brand | ABB |

| Type | I/O Control Board (IOEC) |

| Input Voltage | Typically operates within a specific voltage range suitable for industrial applications, though the exact value might vary depending on the system it’s integrated with. For example, it could be designed to handle common industrial voltages like 24V DC or 110 – 240V AC with appropriate tolerances |

| Operating Temp | Has an operating temperature range of, say, – 10°C to 55°C, which allows it to function reliably in diverse industrial environments, from cold storage facilities to hot manufacturing workshops |

| Communication Method | Supports communication protocols such as CANopen and Modbus, facilitating seamless data transfer between different devices in the industrial network. It may also feature an Ethernet interface for high – speed data exchange and remote monitoring capabilities |

| Mounting | Designed for easy installation, perhaps with a mounting method like DIN – rail mounting, which enables quick and secure attachment within control panels |

| Weight | Approximately 0.71 kg (as per some sources), making it lightweight yet robust enough to withstand industrial vibrations and handling |

| Certifications | Complies with international standards such as IEC 61131 – 2, ensuring its quality and safety in industrial use |

| Dimensions | With dimensions like 18.0″ x 2.0″ x 6.0″ (45.7 cm x 5.1 cm x 15.2 cm) as reported by some sellers, it is compact enough to fit into standard – sized control enclosures |

| IP Rating | Could have an IP rating, for instance, IP20, which protects against solid objects larger than 12 mm, making it suitable for indoor industrial environments where it may be exposed to some dust but not significant water or moisture |

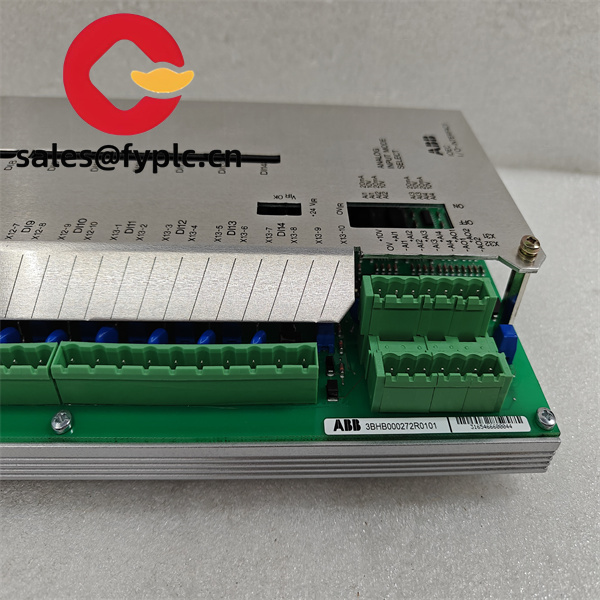

| Digital I/O | Capable of handling a certain number of digital inputs and outputs. For example, it might offer up to 32 digital inputs and 32 digital outputs, allowing for extensive connection to digital – based sensors and actuators |

| Analog I/O | Comes equipped with a set of analog inputs and outputs, such as 8 analog inputs and 8 analog outputs, enabling it to interface with sensors and devices that operate on analog signals, like temperature sensors or variable – speed drives |

Functional Strengths & Design Advantages

The ABB 3BHB003041R0101 UFC719AE01 has been engineered with a focus on high – performance functionality. Its powerful data processing capabilities allow it to handle a large volume of I/O data in real – time. This means that in fast – paced industrial processes, it can quickly analyze incoming sensor data and send out appropriate control signals. For example, in a high – speed packaging line, it can detect a misaligned product in an instant and trigger the necessary adjustments to the packaging machinery.

The build quality of the module is top – notch. Constructed with high – grade materials, it can endure the harsh conditions typical of industrial settings. It can withstand electrical interference, vibrations from heavy machinery, and temperature fluctuations without compromising its performance. This durability ensures long – term reliable operation, reducing maintenance costs and minimizing production downtime. Its design also emphasizes compatibility and ease of integration. Whether it’s connecting to new – generation industrial sensors or interfacing with existing control systems, the 3BHB003041R0101 UFC719AE01 ensures smooth communication and seamless operation.

Industrial Use Cases & Value Scenarios

The ABB 3BHB003041R0101 UFC719AE01 finds extensive application in various industrial sectors. In the manufacturing industry, it is widely used in production lines. For example, in an automotive assembly plant, it can control the movement of robotic arms by processing the signals from position sensors. By accurately managing these I/O signals, it ensures that the robotic arms pick and place parts with precision, thus improving the overall quality of the assembly process and reducing the number of defective products.

In the power generation and distribution industry, the module plays a crucial role. In a power substation, it can monitor and control the status of circuit breakers, transformers, and other electrical equipment. By collecting data from sensors attached to these devices, such as temperature sensors on transformers or status sensors on circuit breakers, it can detect any abnormal conditions early. If a transformer starts to overheat, the 3BHB003041R0101 UFC719AE01 can send an alert and initiate corrective actions, such as activating cooling fans or notifying maintenance personnel. This helps in preventing power outages and protecting expensive electrical equipment, ultimately enhancing the reliability of the power supply.

Compatible and Related Models

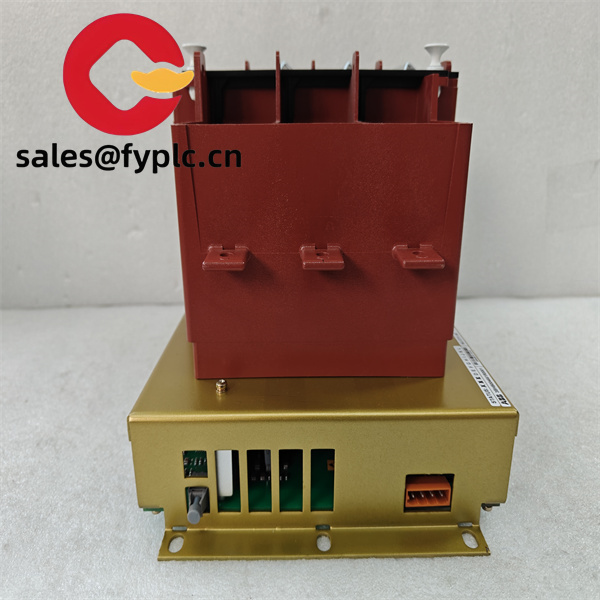

- 3BHB000272R0101 – Another module from ABB that may share some similarities with the 3BHB003041R0101 UFC719AE01 in terms of functionality or physical dimensions. It could be used as an alternative in certain applications where specific requirements are slightly different from what the 3BHB003041R0101 UFC719AE01 offers.

- UFC719AE101 – Related to the UFC719AE01, this model might have some variations in features, perhaps an enhanced version with additional capabilities or different communication options. It can be considered for applications that require more advanced functionality within the same product family.

- 3BHB00072R0101 – This module can be integrated into the same industrial control system as the 3BHB003041R0101 UFC719AE01. Together, they can work in tandem to provide a more comprehensive I/O control solution, for example, handling different types of signals or controlling different parts of a complex industrial process.

- ACS 1000 – A variable – speed drive system from ABB where the 3BHB003041R0101 UFC719AE01 can be used as a key I/O control component. It helps in controlling the operation of motors in the ACS 1000 system, enabling smooth speed regulation and efficient power management.

- ACS 2000 – Similar to the ACS 1000, the 3BHB003041R0101 UFC719AE01 is also compatible with the ACS 2000 variable – speed drive system. It plays a vital role in coordinating the I/O functions related to motor control and system monitoring within the ACS 2000 setup.

Setup & Service Guidance

When installing the ABB 3BHB003041R0101 UFC719AE01, it is crucial to follow proper grounding procedures. Connect the grounding terminal of the module to a reliable earth ground. This not only protects the module from electrical surges but also ensures the safety of the entire industrial control system. Ensure that there is sufficient space around the module for proper ventilation. Heat generated during its operation needs to dissipate effectively, so avoid installing it in a location with poor air circulation. If it has a DIN – rail mounting design, firmly secure it to the rail to prevent vibrations from causing loose connections, which could lead to intermittent failures.

For long – term operation, regular inspections are recommended. Inspect the module at least once every three months. Look for any signs of physical damage, such as cracks in the casing or loose wires. Monitor the operating temperature; if it exceeds the specified range, it could indicate a problem with the internal components or the cooling mechanism. Regularly update the module’s firmware as ABB releases new versions. This helps in fixing software – related bugs, enhancing performance, and improving compatibility with other devices in the system. Keep the module clean from dust and debris, as these can potentially affect its performance over time.

For more information, please click below to learn more:

Be the first to review “ABB 3BHB003041R0101 UFC719AE01 Control Board Analog Motion Input Module” Cancel reply

Reviews

There are no reviews yet.