Description

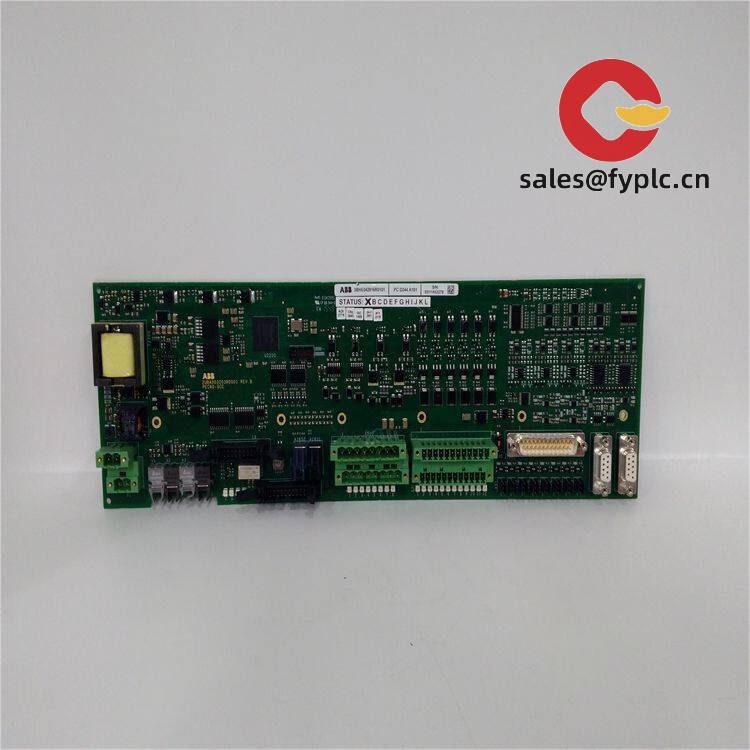

ABB 3BHB004027R0101 — High-Integrity Redundant Power Supply Module for AC/DC Conversion in Critical Control Systems

Let’s cut to the chase: this isn’t just another power supply. The ABB 3BHB004027R0101 is a dual-redundant, hot-swappable 24 VDC power module designed specifically for use in ABB’s 800xA and Symphony Plus DCS cabinets—especially where uptime is non-negotiable. From my experience supporting control system upgrades across oil & gas refineries and pharmaceutical cleanroom utilities, this unit tends to show up wherever a single point of failure could mean hours of unplanned shutdown. One customer in Rotterdam told me they’ve run two of these side-by-side in a safety-critical burner management system for over 5 years—zero field failures, zero unscheduled swaps.

Key Features

- Redundant hot-swap design: Two independent 24 VDC outputs (each rated 20 A) can operate in parallel or take over instantly if one fails—no reboot, no logic interruption.

- Wide-input AC range (85–264 VAC): Handles brownouts and surges common in older plant substations without derating—something I’ve seen simplify retrofit projects significantly.

- Integrated diagnostics via LED + dry contact alarm: You might notice that the front-panel status LEDs don’t just blink—they encode fault types (overvoltage, thermal, short-circuit), and the auxiliary contact feeds directly into your DCS alarm bus.

- UL 61010-1 & IEC 61000-6-2 certified: Meets industrial EMC immunity requirements out-of-the-box—no extra filtering or shielding needed in typical control cabinet environments.

- Convection-cooled, fanless operation: No moving parts means less dust accumulation and quieter operation—especially useful in labs or control rooms near occupied spaces.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB 3BHB004027R0101 |

| HS Code | 85044099 (Other DC stabilised power supplies) |

| Power Requirements | 85–264 VAC, 47–63 Hz; also accepts 100–375 VDC (e.g., for battery-backed applications) |

| Output Voltage / Current | 2 × 24 VDC, 20 A each (derates to 15 A above 50°C) |

| Dimensions (W × H × D) | 45 mm × 230 mm × 255 mm (standard 3U rack width) |

| Weight | Approx. 2.1 kg |

| Operating Temperature | −25°C to +70°C (derated above 50°C; no forced air required) |

| Signal Input/Output Types | Status LEDs (OK, ALARM, FAULT), 1x potential-free alarm contact (NO/NC configurable) |

| Communication Interfaces | None built-in — status signals only; full digital monitoring requires integration via ABB’s S800 I/O or 800xA system bus |

| Installation Method | DIN rail (TS35) mounted vertically in standard 19″ or ABB-specific control cabinets; requires ≥50 mm clearance above/below |

Application Fields

This module typically lands in environments where power continuity directly impacts process safety or regulatory compliance: burner management systems (BMS) in steam generation, emergency shutdown (ESD) logic solvers, critical analyzer signal conditioning racks, and HVAC control panels in GMP-certified pharma suites. It’s also commonly specified for offshore platform control modules—where salt-laden air and limited maintenance windows make reliability a hard requirement, not a nice-to-have.

Advantages & Value

If you’re evaluating this against generic DIN-rail PSUs—or even competing OEM modules—you’ll likely find three things stand out. First, true redundancy behavior: many “redundant” supplies simply share load but won’t isolate faults; this one does. Second, compatibility is baked in—no custom firmware tweaks or gateway adapters needed to talk to ABB’s 800xA engineering tools. Third, from a procurement standpoint, it avoids the hidden cost of integration labor. In many cases, the time saved commissioning (often 1–2 days per cabinet) more than offsets the ~15% premium over commodity units. And yes—it’s fully supported under ABB’s global spare parts program, so long-term obsolescence risk is low.

Installation & Maintenance

Mount it upright on TS35 rail with ≥50 mm free space above and below—don’t stack other heat-generating modules directly adjacent. Ventilation should be natural convection only; avoid enclosed cabinets without at least 0.5 m³/min airflow. Wiring must use 1.5 mm² minimum stranded copper (2× for each output), torqued to 0.6 N·m. Safety-wise: always isolate both AC and DC inputs before servicing—even with hot-swap capability, the internal bus remains live during operation. Routine maintenance? Just visual inspection every 6 months: check for discoloration on terminals, verify LED status matches cabinet documentation, and confirm alarm contacts still trigger correctly in test mode. Firmware updates aren’t applicable—the unit has no microprocessor—but keep your system’s ABB Engineering software current for accurate diagnostics mapping.

Quality & Certifications

It carries CE marking (per EN 61000-6-2/6-4), UL 61010-1 (Industrial Control Equipment), RoHS 2011/65/EU, and conforms to ABB’s internal ISO 9001:2015 quality system. The warranty is straightforward: 365 days from shipment date. If you order today and it’s in stock—which it usually is—we ship within 1 week via FedEx, UPS, or DHL. For larger orders or custom configurations, lead time stays under 30 days. Payment terms are 50% advance, balance before dispatch. And just to be clear: no restocking fees, no hidden logistics charges—what you see is what ships.

Reviews

There are no reviews yet.