Description

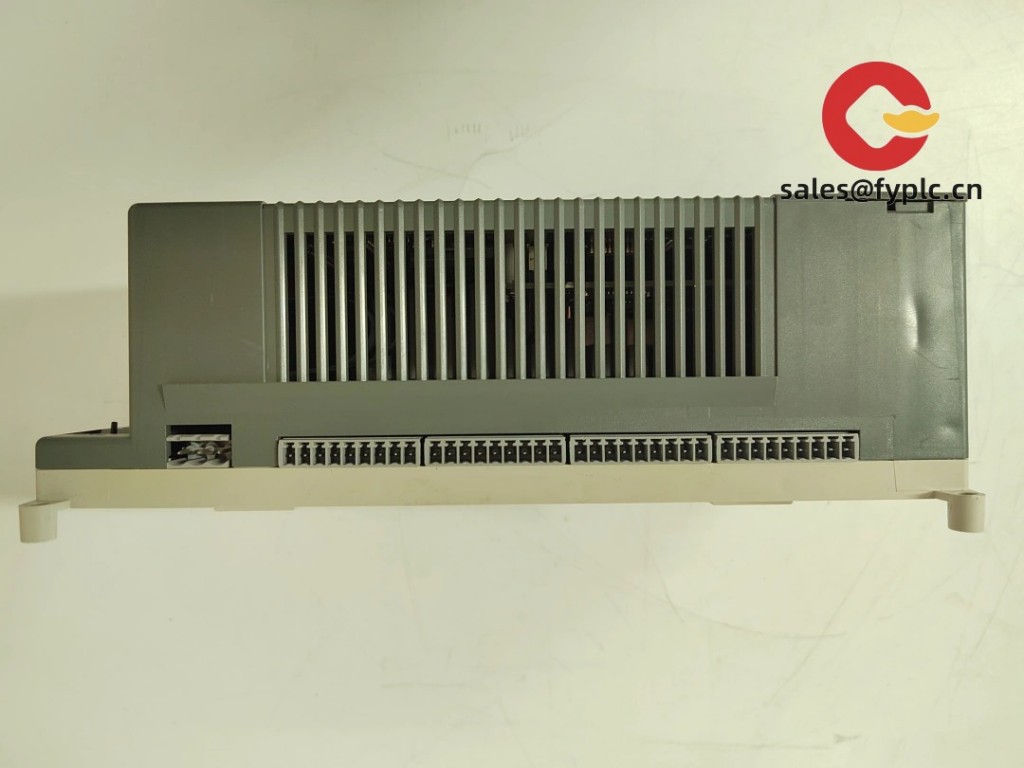

ABB 3BHB005171R0101 – Industrial AC Servo Drive for Precision Motion Control

If you’re working on a CNC machine retrofit or automating a packaging line, the ABB 3BHB005171R0101 typically shows up as a solid choice for reliable servo performance. It’s part of ABB’s well-regarded IRC5 automation platform, commonly found in robotic integration and high-precision industrial applications. From my experience, it stands out not just for its responsiveness but also for how seamlessly it integrates into existing control architectures.

Key Features

- High-performance servo control: Designed to drive AC motors with tight speed and torque regulation—useful in applications like robotic arm positioning where repeatability matters.

- Integrated safety functions: Includes STO (Safe Torque Off), which helps meet machinery safety standards without requiring external relays in many cases.

- Digital diagnostics interface: One thing I appreciate is the real-time feedback during commissioning; troubleshooting motor faults becomes significantly faster compared to older analog drives.

- Modular design: Can be rack-mounted alongside other modules in an IRC5 cabinet, saving space and simplifying cable routing in compact control panels.

- Firmware flexibility: Supports field upgrades, so you’re not locked into outdated logic when expanding your system down the line.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB / 3BHB005171R0101 |

| HS Code | 85371090 |

| Power Requirements | 3-phase AC 400V ±10%, 50/60 Hz |

| Dimensions (H×W×D) | Approx. 250 × 120 × 200 mm |

| Weight | ~3.2 kg |

| Operating Temperature | 0°C to +45°C (with derating above 40°C) |

| Signal I/O Types | Digital inputs/outputs for enable, fault reset, limit switches; analog inputs for speed reference |

| Communication Interfaces | Fieldbus support via DSQC communication module (typically Profibus DP or DeviceNet) |

| Installation Method | DIN-rail or panel mount within IRC5-compatible cabinets |

Application Fields

You might notice this drive turning up in robotics cells—especially ABB IRB series arms used in automotive assembly. But it’s also been deployed in precision cutting machines, labeling systems, and rotary indexing tables. In many cases, users replace aging drives in legacy automation lines where maintaining compatibility with existing motion programs is critical. The closed-loop control makes it suitable for tasks that demand consistent acceleration profiles and minimal overshoot.

Advantages & Value

Procurement teams tend to favor this model because spare units still circulate in secondary markets, reducing long-term obsolescence risk. While it’s not a brand-new generation drive, its proven track record means less engineering time spent validating performance. There’s also value in using a module that communicates natively with ABB RobotWare—fewer protocol converters, fewer failure points. And if your facility already uses IRC5 controllers, swapping in a refurbished 3BHB005171R0101 can save thousands versus upgrading the entire cabinet.

Installation & Maintenance

Install only in enclosed cabinets meeting IP54 standards—this drive doesn’t handle dust well, especially in woodworking or textile environments. Ensure adequate ventilation; stacking multiple drives side by side requires at least 20mm clearance for heat dissipation. Wiring should follow shielded twisted-pair practices, particularly for feedback signals from the resolver or encoder. On the maintenance side, check connection tightness every six months, especially if the machine operates under vibration. Firmware updates are rare but recommended when integrating with newer HMI systems. Calibration isn’t user-serviceable; best handled through certified service centers.

Quality & Certifications

Certified to CE, UL, and RoHS standards—so it clears customs in North America and EU without additional compliance hurdles. Built under ISO 9001-controlled processes, which gives some confidence in consistency even across refurbished batches. Comes with a standard 365-day warranty covering defects in materials and workmanship, excluding damage from incorrect installation or power surges.

Order Placement Process & Guarantees

- Delivery Time: 1 week for in-stock units; no more than one month for backordered or tested refurbished modules.

- Payment Terms: 50% advance payment required to initiate order processing; balance due before shipment.

- Shipping: Dispatched via FedEx, UPS, or DHL—tracking provided upon dispatch.

Reviews

There are no reviews yet.