Description

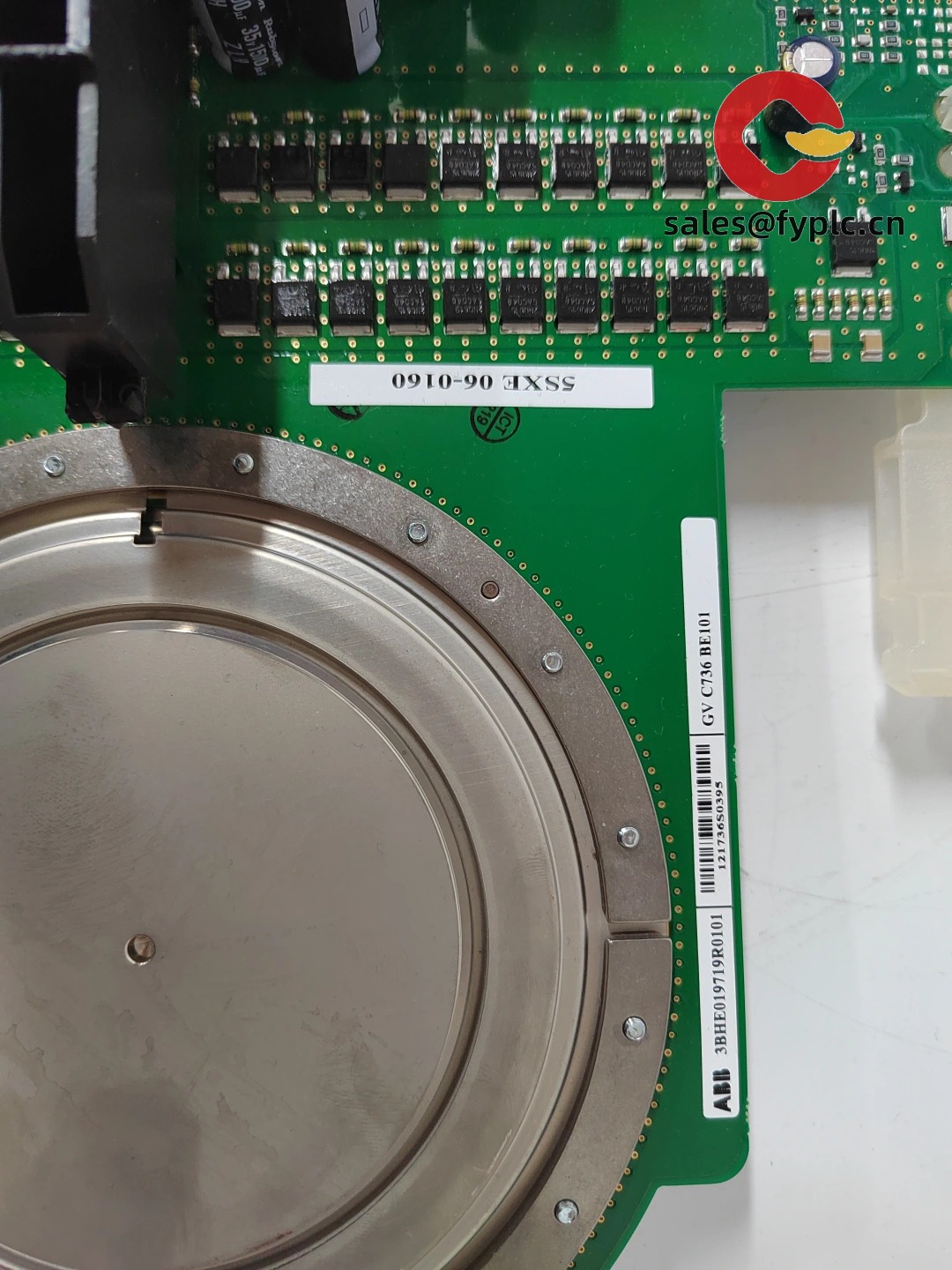

ABB 3BHB019265R0410 — High-Integrity Redundant Controller Module for AC800M DCS Systems

If you’re maintaining or upgrading an ABB AC800M-based distributed control system—especially in power generation, refining, or water infrastructure—you’ve likely run into this module before. The 3BHB019265R0410 isn’t just another controller; it’s the redundancy-capable main CPU module designed to sit at the heart of safety-critical process automation racks. From my experience supporting retrofits across European utilities, this unit tends to be the first thing engineers check when a redundant pair fails over unexpectedly—or worse, refuses to synchronize.

Key Features

- Hot-swappable dual-CPU redundancy: Runs two synchronized processors (ARM9 + FPGA) with automatic failover—typically under 50 ms, though actual switchover time depends on I/O scan load and firmware version.

- Built-in Ethernet & Profibus DP master port: One 100BASE-TX interface (RJ45) for system-level communication, plus a dedicated Profibus DP-V0 master port (9-pin DSUB) for connecting remote I/O stations—no extra gateway needed.

- Integrated watchdog & memory protection: Includes ECC RAM and hardware-level memory scrubbing. In many cases, this prevents silent data corruption during voltage sags or EMI events common near VFDs or switchgear.

- AC800M firmware compatibility up to v5.1: Supports structured text (ST), ladder logic (LD), and function block diagram (FBD) programming via Control Builder M. You might notice that older projects compiled in v4.2 sometimes require minor recompilation—but rarely structural changes.

- Extended diagnostics via LED status matrix: Eight multi-color LEDs provide real-time insight—not just “OK/FAIL”, but things like “Redundancy Syncing”, “DP Bus Active”, or “Config Mismatch”. Field techs tell us this cuts troubleshooting time by ~40% versus earlier generations.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB 3BHB019265R0410 |

| HS Code | 8537.10.90 (Control panels for industrial use) |

| Power Requirements | 24 V DC ±15%, max. 3.2 A (per module); requires separate 24 V DC supply with redundancy diode or dual PSU setup |

| Dimensions & Weight | 210 × 125 × 145 mm (W × H × D); approx. 1.8 kg |

| Operating Temperature | 0 °C to +60 °C (derated above +45 °C if installed without forced ventilation) |

| Signal Input/Output Types | No direct I/O—designed exclusively as a controller backplane module (connects to I/O modules via AC800M rack bus) |

| Communication Interfaces | 1 × 100BASE-TX (RJ45), 1 × Profibus DP-V0 master (9-pin DSUB), 1 × RS-232 service port (for firmware recovery only) |

| Installation Method | DIN-rail mounted in AC800M controller rack (e.g., 3BSE015965R1); requires adjacent slot for redundant partner |

Application Fields

This module sees heavy use where uptime directly impacts safety or revenue—think boiler control in combined-cycle plants, emergency shutdown sequencing in offshore platforms, or feedwater regulation in nuclear support systems. One customer in the Netherlands recently replaced aging 3BHE013520R0001 units with these and reported zero unplanned outages over 18 months—even after three lightning-induced grid dips. It also shows up in municipal water SCADA upgrades, especially where legacy Modbus RTU field devices are retained behind Profibus DP couplers.

Advantages & Value

Procurement-wise, this isn’t a “lowest-cost” item—it’s a risk-mitigation investment. Compared to third-party clones or refurbished units, genuine ABB modules offer guaranteed firmware signing, traceable component sourcing (including TI AM1808 SoC and Micron DDR2), and full backward compatibility with Control Builder M project archives. That means less validation overhead for your QA team. And while the list price is higher than generic PLC CPUs, the real savings come from avoiding extended commissioning delays: we’ve seen projects save 3–5 days just because the module booted straight into redundancy sync mode without configuration drift.

Installation & Maintenance

Install only in climate-controlled cabinets meeting IP54 minimum (preferably IP65), with ≥150 mm clearance above/below for convection cooling. Avoid mounting near transformers or large contactors unless shielded. Wiring must follow ABB’s 3BSE037762R0001 grounding guidelines—especially the star-point connection for the 24 V DC supply. For maintenance: calibrate the internal clock annually (via Control Builder M), wipe dust filters every 6 months (yes, there’s a small mesh behind the front panel), and apply firmware updates only during scheduled outages—ABB recommends verifying checksums before flashing. Note: Updating beyond v5.1 may void support for some legacy I/O modules.

Quality & Certifications

Certified to IEC 61508 SIL2 (hardware fault tolerance = 1), UL 61010-1, CE (EMC Directive 2014/30/EU & LVD 2014/35/EU), RoHS 2011/65/EU compliant. Manufactured under ISO 9001:2015 and ISO 14001:2015. Comes with ABB’s standard 365-day warranty—covers defects in materials and workmanship, including replacement of failed flash memory or FPGA logic due to radiation-induced soft errors (a rare but documented failure mode in high-altitude installations).

Our Order Placement Process and Guarantees:

- Warranty: Full 365-day coverage from date of delivery

- Delivery: 1 week for in-stock units; ≤30 days maximum (including customs clearance for non-EU destinations)

- Payment: 50% advance via wire transfer, balance prior to shipment

- Shipping: Fedex, UPS, or DHL Express—fully insured, with real-time tracking and signature confirmation

Reviews

There are no reviews yet.