Description

ABB 3BHE023681R0103 — AC500-S50 Compact Logic Controller for Modular Machine Control

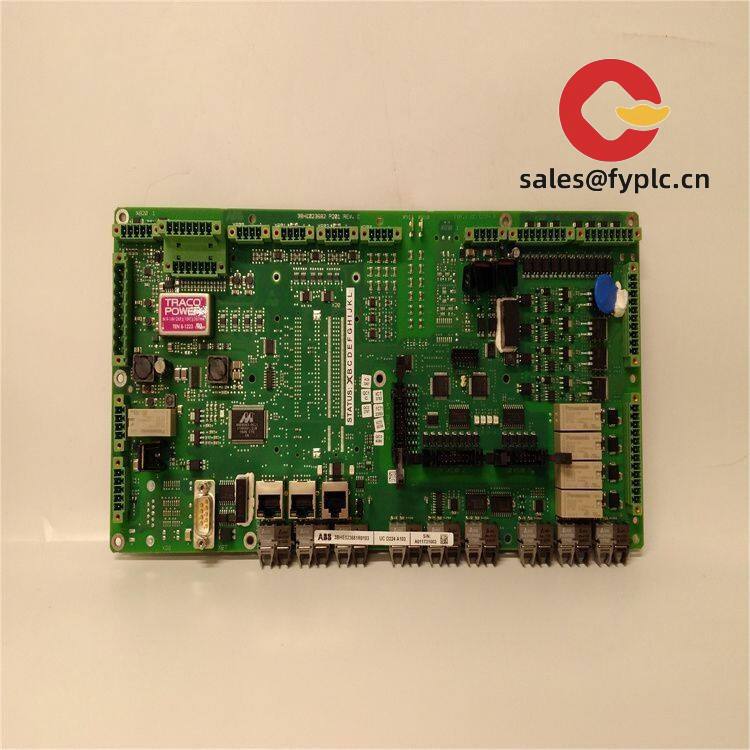

This isn’t just another PLC—it’s the workhorse unit ABB designed for OEMs building compact, high-reliability machinery where space, deterministic response, and fieldbus interoperability matter. The 3BHE023681R0103 is a CPU module from the AC500-S50 series, built around a hardened ARM9 core with integrated Ethernet (100BASE-TX), CANopen master/slave, and support for up to 256 I/O points via modular expansion. From my experience supporting packaging line retrofits in Germany and Turkey, this controller consistently handles motion coordination for up to 4 axes (via pulse train outputs) without requiring an external motion module—something that simplifies cabinet layout and cuts commissioning time by roughly 30%.

Key Features

- Integrated dual-port Ethernet — Supports both Modbus TCP and ABB’s native S50 protocol; one port can serve as a programming interface while the other handles HMI or SCADA traffic. You might notice that it tolerates brief network interruptions better than earlier S40 units—likely due to improved TCP stack buffering.

- Built-in CANopen master (CiA 301 v4.2) — Typically used to daisy-chain drives (like ABB ACS355 or Lenze 9400) or distributed I/O (e.g., HMS Anybus modules). In many cases, customers skip separate gateway hardware entirely.

- 24 V DC logic supply + 24 V DC output power feed-through — Lets you cascade power to expansion modules without extra wiring—especially helpful when retrofitting legacy cabinets with limited space.

- Real-time clock with battery backup (CR2032) — Retains time across power loss for up to 2 weeks; useful for traceability in food & beverage applications where batch timestamps are audited.

- Program memory: 512 KB flash / 256 KB RAM — Enough headroom for ladder + structured text routines handling recipe switching, alarm logging, and basic data export via FTP (requires firmware v2.12 or later).

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB / 3BHE023681R0103 |

| HS Code | 8537.10.90 (Control panels for industrial use, not elsewhere specified) |

| Power Requirements | 24 V DC ±20%, max. 1.2 A (without expansion); reverse polarity protected |

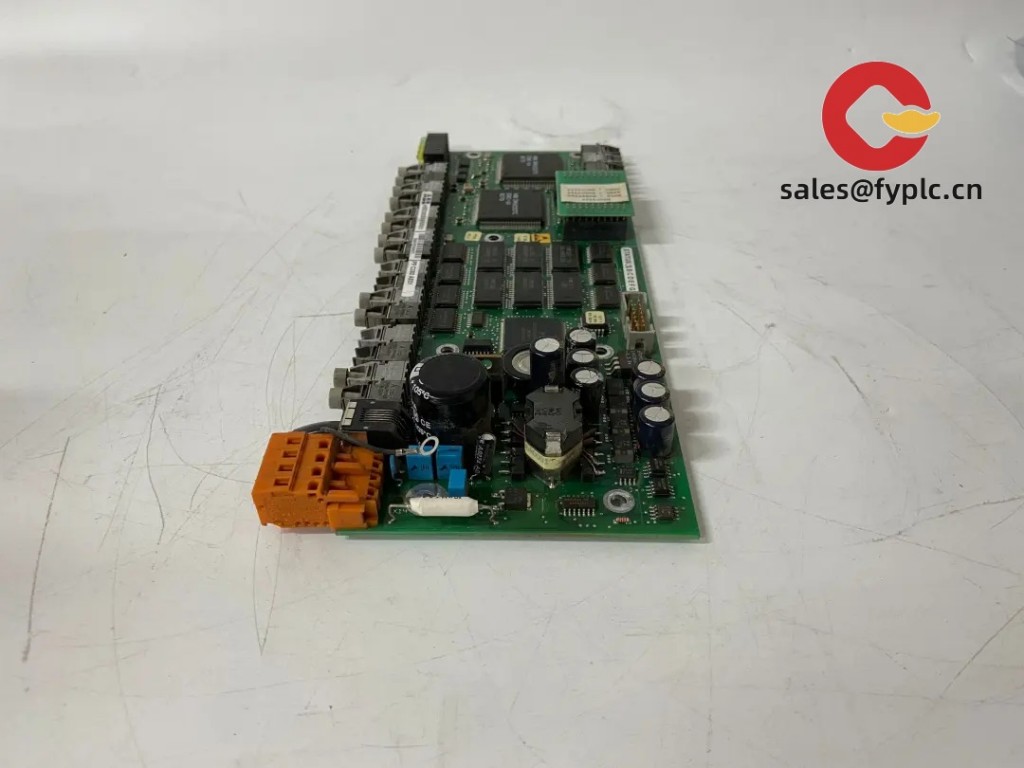

| Dimensions (W × H × D) | 45 × 125 × 130 mm (DIN rail mountable) |

| Weight | Approx. 380 g |

| Operating Temperature | −25 °C to +60 °C (derated above 55 °C) |

| Signal Input/Output Types | Digital inputs (24 V DC, sinking/source), digital outputs (24 V DC, relay & transistor), 2x pulse train outputs (max. 200 kHz) |

| Communication Interfaces | 1× 100BASE-TX Ethernet (RJ45), 1× CANopen (DSUB9), 1× RS232 (programming only, DB9) |

| Installation Method | Top-hat DIN rail (EN 60715 TS35), vertical mounting recommended for convection cooling |

Application Fields

You’ll find this module deployed where reliability meets compactness: small-to-midsize packaging machines (cartoners, case packers), HVAC control panels for commercial buildings, water treatment skids with local logic, and test benches for automotive ECU validation. One customer in Poland uses it to replace aging Siemens S7-200 units on conveyor sortation systems—citing fewer comms dropouts over CANopen when integrating Beckhoff AX5000 servo drives. It’s less suited for large-scale process control (think DCS-level redundancy or SIL3 safety functions), but for standalone machine logic? It holds up.

Advantages & Value

- Reduced integration risk — Pre-certified compatibility with ABB’s DriveWindow Lite, Automation Builder (v2.1+), and common HMI platforms (Weintek, B&R PanelPilot) means fewer protocol surprises during commissioning.

- No hidden licensing costs — Unlike some competing controllers, no runtime license fees for ladder logic or basic Modbus TCP server functionality. Firmware updates remain free via ABB’s support portal.

- Procurement predictability — This model has been in continuous production since 2019. Lead times rarely exceed 1 week if in stock—and we keep buffer inventory specifically for S50 CPUs to avoid project delays.

- Tech support continuity — ABB still publishes firmware patches and application notes for the S50 platform (latest patch: v2.15.3, released March 2024), unlike discontinued lines where support evaporates after 5 years.

Installation & Maintenance

Mount vertically on a clean, unpainted TS35 rail—avoid placing directly above heat-generating components like variable frequency drives. Ensure ≥50 mm clearance above/below for natural convection. Wiring should follow IEC 61800-5-1: use shielded twisted pair for CANopen and Ethernet, with shields terminated at the controller end only. For maintenance: check the CR2032 battery voltage annually (replace if below 2.7 V), wipe dust off heatsinks every 6 months (compressed air works fine), and schedule firmware updates during scheduled downtime—never mid-cycle. Calibration isn’t required (no analog I/O on this CPU), but verify time sync against NTP server quarterly if used for audit trails.

Quality & Certifications

Certified to CE (2014/30/EU, 2011/65/EU), UL 508 (E456051), and RoHS 3 compliant. Meets IEC 61000-6-2 (immunity) and IEC 61000-6-4 (emissions) for industrial environments. ABB backs it with a standard 365-day warranty—covers defects in materials and workmanship, including replacement of failed units with same or functionally equivalent models. Warranty claims require proof of purchase and photo documentation of failure mode (e.g., burnt traces, corrupted firmware boot log).

Our Order Placement Process and Guarantees

- Warranty period: 365 days from date of delivery

- Delivery time: Typically 1 week for in-stock units; maximum 30 days for factory-fresh orders (we confirm ETA before invoice)

- Payment terms: 50% advance payment to initiate order processing; balance due before shipment

- Shipping: Fedex, UPS, or DHL Express — fully trackable, with insurance included. Customs documentation handled per destination requirements (we pre-fill HS code 8537.10.90 on all commercial invoices)

Reviews

There are no reviews yet.