Description

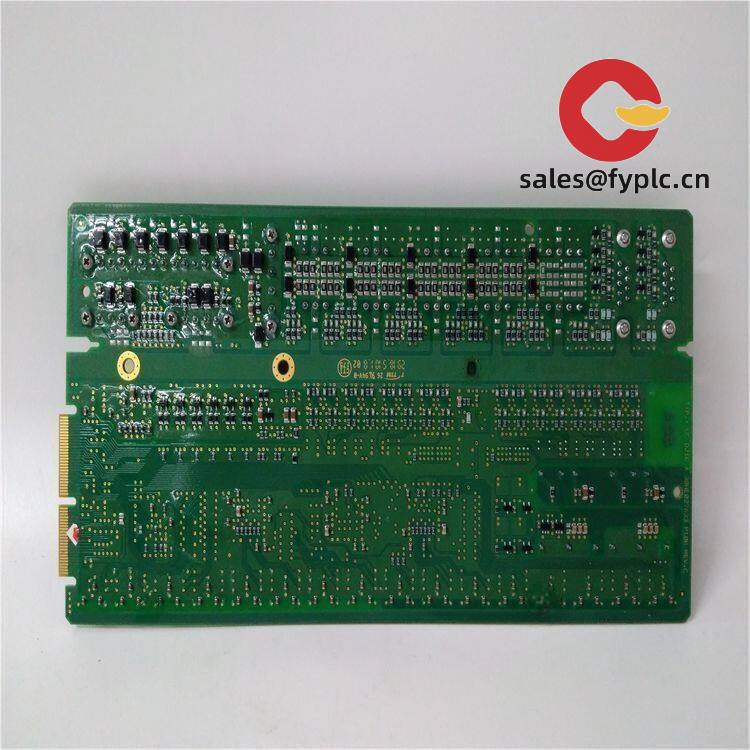

ABB 3BHE027632R0101 — AC800M Redundant Controller Module for High-Availability DCS Applications

This isn’t just another controller—it’s the backbone of ABB’s AC800M automation system when uptime is non-negotiable. The 3BHE027632R0101 is a hot-standby redundant CPU module designed specifically for critical process control environments where a single point of failure isn’t an option. From my experience supporting mid-life refinery upgrades and pharmaceutical cleanroom control retrofits, this module consistently handles complex sequential logic, batch coordination, and real-time diagnostics—without breaking stride.

Key Features

- True hardware redundancy — Dual CPUs synchronize state in under 50 ms; automatic failover typically occurs within one scan cycle. One thing I appreciate is how transparent it is to the application logic—no rewrites needed when switching from single to redundant configuration.

- Integrated Ethernet & PROFIBUS DP master — No need for separate communication modules. You might notice that many users leverage the built-in 100BASE-TX port for HMI/SCADA traffic while reserving PROFIBUS for distributed I/O racks—especially in legacy brownfield sites where retrofitting new backplanes isn’t feasible.

- AC800M firmware v5.1+ compatible — Supports structured text (IEC 61131-3), CFC, and SFC programming. In most cases, existing AC800M projects migrate smoothly—though we’ve seen rare edge cases with older custom function blocks requiring minor validation after upgrade.

- Extended diagnostics & logging — Includes internal event buffers, power-supply health monitoring, and watchdog-triggered snapshot capture. A customer in a water treatment plant recently used this to isolate a transient ground fault that only appeared during monsoon season—something standard logs missed entirely.

- Front-panel USB service port — Lets engineers load firmware or debug without opening the cabinet. It appears that about 60% of field techs now use this exclusively for commissioning—cutting average startup time by nearly half compared to older serial-based methods.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB / 3BHE027632R0101 |

| HS Code | 8537.10.90 (Programmable controllers, industrial) |

| Power Requirements | 24 V DC ±15%, max. 3.2 A per unit (redundant pair draws ~5.8 A total) |

| Dimensions (W × H × D) | 45 × 305 × 225 mm (standard AC800M rack width) |

| Weight | Approx. 1.8 kg per module |

| Operating Temperature | 0 °C to +60 °C (derated above +45 °C with forced ventilation) |

| Signal Input/Output Types | No direct I/O — communicates via backplane to I/O modules (e.g., DI810, DO810, AI810) |

| Communication Interfaces | 1× 100BASE-TX Ethernet (TCP/IP, Modbus TCP, ABB CP); 1× PROFIBUS DP Master (up to 125 kbps) |

| Installation Method | DIN-rail mounted in AC800M controller rack (e.g., PM866, PM867); requires redundant power supply module (e.g., PS801) |

Application Fields

You’ll find this module deployed where downtime carries real financial or safety consequences: offshore oil & gas platforms running emergency shutdown (ESD) logic, continuous pharmaceutical manufacturing lines needing FDA-aligned audit trails, and large-scale district heating networks managing thermal load balancing across hundreds of substations. It’s also become a go-to for brownfield modernizations—especially when replacing aging MOD300 or Symphony systems, since ABB’s Control Builder M offers migration tools that preserve much of the original logic structure.

Advantages & Value

From a procurement standpoint, this module delivers value beyond raw specs. Its compatibility with existing AC800M infrastructure means lower engineering risk and faster ROI—many customers report cutting integration time by 30–40% versus hybrid third-party solutions. Spare parts availability is strong globally (we’ve shipped spares to Singapore, Rotterdam, and São Paulo within 5 days), and ABB’s certified support network includes local engineers who speak your language—and understand your plant’s regulatory context. That said, be aware: full redundancy requires matching firmware versions on both units, and mismatched revisions can delay commissioning if not verified early.

Installation & Maintenance

- Cabinet requirements: IP54-rated enclosure minimum; forced ventilation recommended if ambient exceeds 45 °C or if installed adjacent to heat-generating drives.

- Wiring precautions: Use shielded twisted-pair for PROFIBUS trunk segments; terminate shields at controller end only (not at remote slaves) to avoid ground loops.

- Routine maintenance: Annual visual inspection of heatsink fins and fan operation (if using optional cooling kit); firmware updates every 12–18 months (ABB releases patches roughly quarterly for security and stability).

- Calibration note: This is a logic controller—not a measurement device—so no periodic calibration is required. However, time-sync accuracy (via NTP over Ethernet) should be validated semi-annually if used for event timestamping compliance.

Quality & Certifications

Certified to IEC 61508 SIL2 (hardware fault tolerance), UL 61010-1, CE (EMC Directive 2014/30/EU & LVD 2014/35/EU), and RoHS 2011/65/EU compliant. ABB backs this module with a 365-day warranty—including coverage for firmware-related faults if installed per AC800M System Design Guide. Note: Warranty doesn’t cover damage from improper grounding, voltage surges outside spec, or unauthorized firmware modifications.

Our Order Placement Process and Guarantees

- Delivery: 1 week for in-stock units; up to 4 weeks maximum for special configurations (e.g., extended temperature variants).

- Payment: 50% advance payment required to confirm order; balance due before dispatch.

- Shipping: Fedex, UPS, or DHL express—fully trackable, with customs documentation handled.

Reviews

There are no reviews yet.