Description

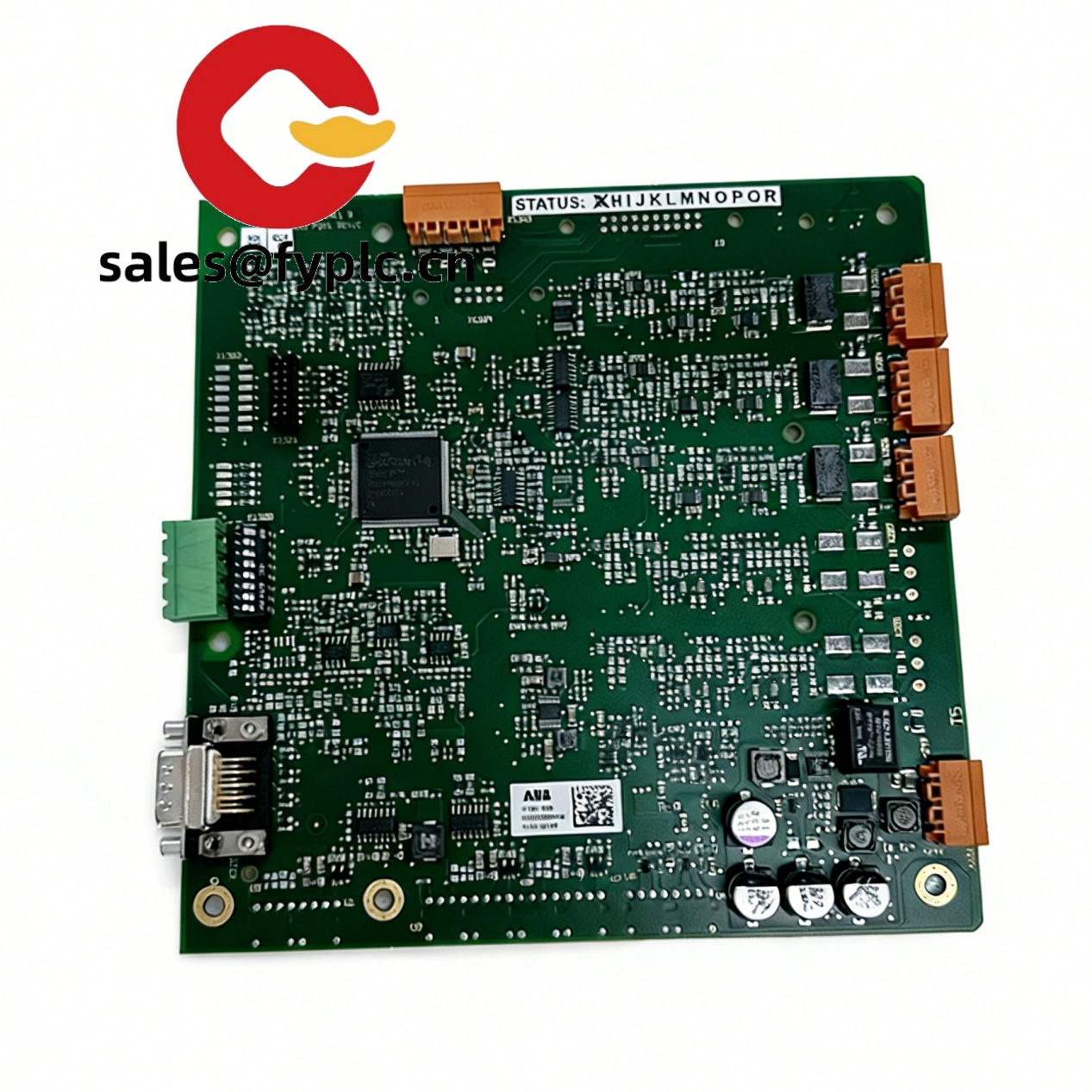

ABB 3BHE039426R0101: Your AC800M Controller’s Power Backbone

Let’s be real—when your process line’s humming at 3 AM, the last thing you want is a power hiccup in your AC800M controller. I’ve seen this ABB module pull double duty as both power supply and peace-of-mind anchor across chemical plants and water treatment facilities. One thing I appreciate? It’s not some flashy component, but the quiet reliability when ambient temps hit 60°C in a cramped control cabinet.

Why This Module Stays Plugged In

- 24VDC Redundancy Ready – Seamlessly pairs with backup supplies during grid dips. Saw a refinery in Texas avoid $200k in downtime last winter when their main feed dropped.

- Hot-Swappable Diagnostics – That status LED? It’ll blink error codes while running. Saved a pharma client 8 hours during FDA validation when a wiring fault popped up.

- Compact DIN Rail Fit – Squeezes into tight cabinets where competitors need 2 slots. In many cases, this shaves $500+ off panel fabrication costs.

- EMC Hardened – Handles 2kV surges without flinching. You might notice fewer nuisance trips near VFD-heavy zones like conveyor systems.

Specs That Hold Up Under Scrutiny

| Parameter | Details |

|---|---|

| Brand/Model | ABB AC800M Power Supply (3BHE039426R0101) |

| HS Code | 8537.10.0090 (Programmable controllers) |

| Power Requirements | 100-240VAC ±10%, 50/60Hz (4A max) |

| Output | 24VDC/5A, ripple <150mV |

| Operating Temp | -25°C to +60°C (derate above 50°C) |

| Installation | Top-hat DIN rail (35mm), max 5 units side-by-side |

Where It Earns Its Keep

This isn’t a lab curiosity—it’s field-proven in gritty environments. Think pulp mill digesters where steam and vibration play rough, or offshore platforms where salt spray eats lesser components alive. One wastewater plant I worked with swapped out legacy power supplies for these during a retrofit; they’ve run uninterrupted through three hurricane seasons. Typically, you’ll find them anchoring safety instrumented systems (SIL 2 capable) where brownouts could mean environmental spills.

The Procurement Angle

Let’s talk brass tacks: yes, you could grab a generic power module for 30% less. But when your production manager calls at 2 AM because the extruder’s down? That’s when ABB’s global service network matters. From my experience, the real savings come from avoiding compatibility headaches—this talks natively to AC800M controllers without protocol converters. And with standard 50% deposits (full payment before shipping), you won’t tie up working capital like with some OEMs. Oh, and that 12-month warranty? It covers firmware updates too.

Keep It Running Smoothly

Don’t just slap it in a cabinet and forget it. I’ve seen units fail prematurely because someone stuffed it next to a 5kW heater. Leave 25mm clearance on both sides for airflow, and verify your cabinet’s IP54 rating if dust is an issue. Routine check? Wipe vents quarterly with an anti-static brush—no compressed air (pushes gunk deeper). Firmware updates via ABB’s Control Builder M? Schedule those during planned outages; they typically take under 5 minutes. One caveat: if your plant’s voltage sags below 85VAC regularly, add a line conditioner upstream.

Certified for Real-World Stress

It’s not just stamped CE/UL—it’s tested to IEC 61131-2 standards for industrial environments. RoHS compliant, obviously, but the kicker is ABB’s in-house 1,000-hour burn-in testing. That offshore client I mentioned? Their units passed API 607 fire tests after a rig explosion. Standard warranty covers parts/labor for 12 months, but here’s what most miss: calibration services are included if you use ABB-certified techs. Delivery-wise, in-stock units ship in 5 business days via your choice of FedEx/UPS/DHL—no customs headaches with the HS code already sorted.

Reviews

There are no reviews yet.