Description

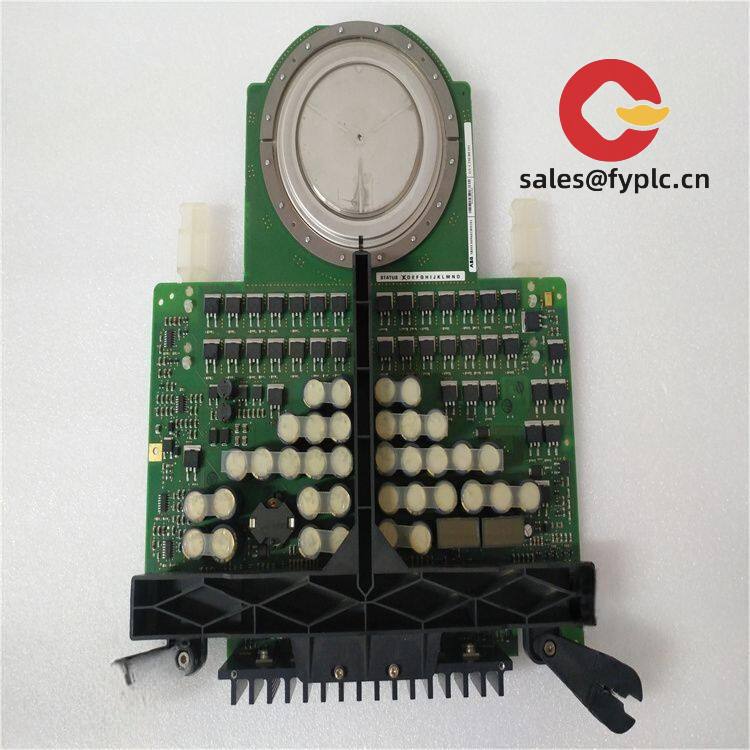

ABB 3BHL000386P0101 IGCT Module – High-reliability press-pack device for medium-voltage drives and heavy-duty converters

The ABB 3BHL000386P0101 is an IGCT (Integrated Gate-Commutated Thyristor) module designed for demanding power conversion tasks where uptime and thermal robustness matter—typically medium-voltage drive systems, large rectifiers, and grid-connected converters. From my experience, maintenance teams choose IGCT press-pack modules like this when they need high surge capability, low conduction losses, and predictable end-of-life behavior in mission-critical environments.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment terms: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

One thing I appreciate is how straightforward this model is to source and integrate as a like-for-like replacement. You might notice that it typically drops into existing ABB MV drive stacks with only standard re-clamping and gate connection checks.

Key Features

- Press-pack reliability: Mechanical clamping provides uniform current sharing and robust thermal cycling behavior, well-suited for high-power stacks.

- IGCT switching performance: Fast turn-off capability compared with classic thyristors, enabling efficient four-quadrant converters and regenerative drives.

- Low conduction losses: Helps reduce heat load in MV drive cells, which in many cases improves overall system efficiency and cooling margins.

- Service-friendly form factor: Designed for stack-mounted installation; replacement usually involves de-clamping, surface cleaning, and re-clamping with proper force.

- Stable under tough duty cycles: Handles repetitive high dI/dt and surge conditions common in cement, mining, steel, and marine applications.

- Compatible gate connection: Coaxial gate interface to the IGCT gate unit; anode/cathode via press-pack electrodes for low-inductance paths.

Technical Specifications

| Brand / Model | ABB / 3BHL000386P0101 |

| Product Type | IGCT power semiconductor module (press-pack) |

| HS Code | 8541.30 (Thyristors, diacs and triacs, other than photosensitive devices) |

| Power Requirements | Passive device; driven by an external IGCT gate unit (no onboard power supply) |

| Signal Input / Output | Press-pack anode/cathode electrodes; coaxial gate connection to gate driver |

| Communication Interfaces | None (power semiconductor component) |

| Installation Method | Press-pack clamped in a stack between heat sinks; follow ABB clamping force and surface cleanliness guidelines |

| Operating Environment | Industrial drive cabinet with adequate cooling and dust protection; observe system ambient limits |

Application Fields

This model is typically used in:

- Medium-voltage variable-speed drives in cement, mining, metals, oil & gas, and marine propulsion

- High-power rectifier and inverter stages for grid-connected converters and regenerative systems

- Static VAR compensators and FACTS equipment where fast, rugged switching is required

- Large test benches and power supplies that demand low-loss, high-current switching elements

A maintenance manager at a clinker line mentioned that replacing a worn device with a 3BHL000386P0101 restored an MV drive to service the same shift—no parameter changes were needed, just careful re-clamping and gate lead checks. That seems to be the common experience when the stack is in good mechanical shape.

Advantages & Value

- Reliability under stress: Press-pack IGCT design tolerates thermal cycling and fault currents better than many packaging styles.

- Compatibility: Fits established ABB MV drive architectures; in many cases it’s a direct spare for existing stacks.

- Lower lifecycle cost: Reduced conduction losses and long service intervals can translate into fewer shutdowns and lower cooling overhead.

- Procurement confidence: Genuine, traceable ABB parts with defined warranty and rapid shipment options.

- Technical support: Guidance on clamping, surface preparation, and gate unit checks to shorten downtime.

Installation & Maintenance

- Cabinet environment: Keep the drive cabinet clean and well-ventilated; confirm fans/filters and heat exchanger flows meet OEM specs.

- Stack preparation: Clean and inspect heat sink contact surfaces; remove oxidation and debris. Use fresh, approved thermal interface material or foils.

- Clamping: Apply the specified clamping force uniformly using calibrated tooling. Avoid tilt or point-loading to protect the press-pack.

- Electrical connections: Verify low-inductance busbar paths; check the gate coax for damage and correct polarity to the gate unit.

- Safety: Lock-out/tag-out, discharge DC link, and confirm zero energy; IGCTs can store charge and the DC link can remain energized.

- Routine checks: Periodically inspect for hot spots, loose hardware, contamination, and coolant performance (air or water). Replace filters and refresh thermal compound during planned outages.

Quality & Certifications

- Quality system: Manufactured under ABB’s ISO 9001 quality management

- Compliance: RoHS compliant component; suitable for CE-compliant assemblies when integrated per standards

- Warranty: 365 days from delivery

Related Supporting Components (for integration)

- IGCT gate unit (matching the converter design)

- Coaxial gate cable and verified gate connectors

- Press-pack clamping hardware and calibrated torque/force tools

- Heat sink assembly (air- or water-cooled) with approved thermal interface media

- Busbar hardware and insulation accessories rated for the MV stack

Reviews

There are no reviews yet.