Description

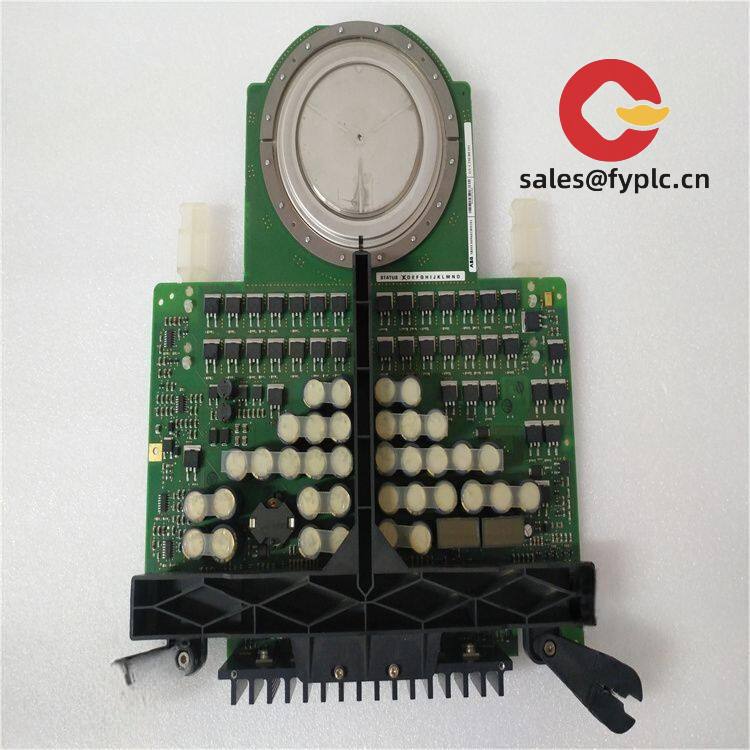

ABB 3BHL000388P0101 IGCT Module – High‑reliability power switching for medium‑voltage drives and converters

The ABB 3BHL000388P0101 is an IGCT (Integrated Gate-Commutated Thyristor) module designed for heavy-duty industrial converters and medium‑voltage drive stacks. From my experience, this part is typically specified as a direct replacement in ABB-engineered power cells, where long life, fast turn‑off, and rugged surge handling matter more than anything else. If you’re maintaining MV drives, STATCOM/SVC converters, or high-power rectifier bridges, this module keeps downtime low and thermal margins healthy.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than 1 month at the latest

- Payment terms: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- IGCT switching technology – Combines low conduction losses with fast, reliable turn‑off, ideal for medium‑voltage power stages.

- Rugged surge capability – Handles demanding load changes and grid disturbances common in heavy industry.

- Thermal stability – Designed to interface tightly with a dedicated heat sink, keeping junction temperatures within safe limits.

- Gate drive compatibility – Works with ABB gate driver units (GDU) specified for the 3BHL000388P0101, typically using isolated trigger/control.

- Service-friendly replacement – Mechanical footprint and terminals laid out for straightforward swap during planned shutdowns.

- Quality-controlled sourcing – Genuine ABB part number for like‑for‑like maintenance in ABB converter stacks.

Technical Specifications

| Brand / Model | ABB / 3BHL000388P0101 |

| Product Type | IGCT Power Semiconductor Module |

| HS Code | 8541.29 (Thyristors and similar semiconductor devices, other than photosensitive) |

| Power Requirements | Not applicable (power device within a converter stack; gate unit supply provided by the drive’s GDU) |

| Signal Input/Output | Gate control via dedicated ABB gate driver; high‑current power terminals (anode/cathode). In many cases, an NTC temperature sensing path is available via the stack design. |

| Communication Interfaces | None on device (control handled by the associated GDU within the converter) |

| Operating Temperature | Typically suitable for MV drive enclosures 0 to +40 °C ambient; junction temperatures per ABB limits when correctly heatsinked |

| Dimensions & Weight | Per ABB drawing for 3BHL000388P0101; consult the mechanical outline for mounting hole pattern and clearances |

| Installation Method | Bolted to heat sink / cold plate within the power cell; observe flatness, torque, and thermal interface material requirements |

| Typical Use | Medium‑voltage drives, grid converters (STATCOM/SVC), high‑power rectifiers and choppers |

Application Fields

You’ll most often see this module inside ABB medium‑voltage drive power cells and utility‑scale converter stacks where high current and high dv/dt are daily business. Common scenarios include:

- Cement kiln and raw mill main drives where thermal cycling and dust are constant.

- Steel rolling mill stands and coilers that demand strong overload capability.

- Compression and pumping trains in oil & gas and chemical plants, typically running 24/7.

- Desalination high‑lift pumps and municipal water MV drives with tight uptime SLAs.

- FACTS equipment (STATCOM/SVC) stabilizing reactive power on transmission networks.

A maintenance supervisor at a coastal desalination site told us the IGCT swap with correct torqueing and fresh TIM brought device temps down a few degrees at the same load—small change, big reliability win over the summer.

Advantages & Value

- Reliability under stress – IGCTs tend to be forgiving during grid faults and motor transients, reducing nuisance trips and unplanned stops.

- Designed-in compatibility – Genuine ABB part number for the exact stack design that calls for 3BHL000388P0101, minimizing commissioning risk.

- Lower lifecycle cost – Fewer thermal failures and straightforward service procedures usually mean fewer emergency callouts and spares churn.

- Technical support – We can coordinate drawings, torque specs, TIM recommendations, and installation notes to help your team complete the swap confidently.

Installation & Maintenance

- Cabinet environment – Install inside a sealed MV drive or converter cabinet with proper forced air or liquid cooling. Keep ambient typically 0–40 °C unless your design states otherwise.

- Heat sink preparation – Verify surface flatness and cleanliness; apply approved thermal interface material (thin, uniform layer). Use a calibrated torque wrench to specified values.

- Wiring & isolation – Follow lockout/tagout. Respect creepage/clearance. Route any fiber‑optic gate links (if applicable via GDU) with clean connectors and proper bend radius.

- Safety – Only qualified MV personnel should handle IGCT modules. Discharge DC links and verify zero energy before touching power circuits.

- Routine checks – Inspect mounting torque after initial thermal cycles; ensure heat sinks and filters are clean; confirm gate driver health and firmware per OEM guidance.

- Spare strategy – For mission‑critical lines, it seems wise to hold at least one spare per power cell to avoid prolonged outages.

Quality & Certifications

- Manufactured by ABB under ISO 9001 quality management.

- RoHS compliance typically applicable for the component level; documentation available on request.

- CE/UL marking may apply at the system or assembly level; this device is intended as a component inside certified equipment.

- Standard warranty: 12 months from delivery.

Common Supporting Components

- ABB Gate Driver Unit (GDU) matched to 3BHL000388P0101 triggering and protection strategy.

- Fiber‑optic trigger cables (where used by the GDU architecture).

- Approved thermal interface materials and specified heat sink/cold plate assemblies.

- Snubber networks and dv/dt limiting components per the converter design.

If you’d like, share your cabinet type or drive/converter part list. One thing I appreciate is matching torque specs, TIM, and the exact GDU revision in advance—it usually saves a truck roll later.

Reviews

There are no reviews yet.