Description

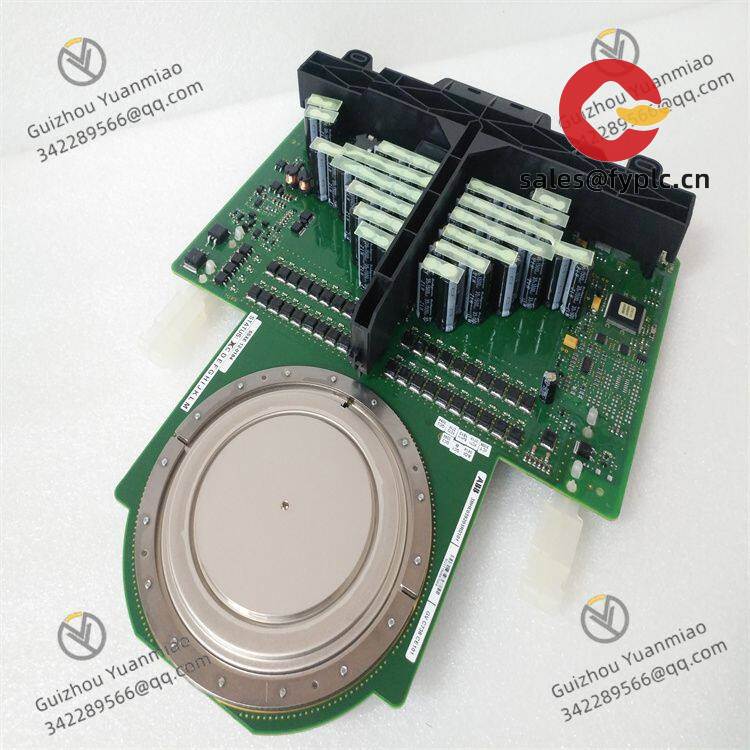

ABB 3BHL000392R0101 IGCT Module – High‑power switching element for medium‑voltage drives and converters

The ABB 3BHL000392R0101 is an IGCT (Integrated Gate‑Commutated Thyristor) module used in high‑power converter stacks where reliability and efficient turn‑off behavior matter—typically medium‑voltage AC drives, STATCOM/SVC systems, and large industrial rectifiers. From my experience, this part is chosen as a form‑fit spare in ABB MV drive platforms because it delivers robust press‑pack reliability and low losses under heavy cyclic loads. You might notice that maintenance teams prefer IGCTs for their predictable clamping behavior and solid thermal cycling endurance, especially in harsh duty cycles like rolling mills or marine propulsion.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in‑stock items; no more than one month at the latest

- Payment terms: 50% advance payment; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- IGCT architecture – Combines low conduction loss with fast, reliable turn‑off, suitable for high di/dt applications.

- Press‑pack construction – Clamped (boltless) design that typically tolerates thermal cycling better than plastic modules.

- High power density – Supports compact converter stacks and, in many cases, reduces heat‑sink footprint.

- Low switching losses – Helps improve system efficiency and can lower operating temperatures under comparable load.

- Gate driver compatibility – Works with ABB IGCT gate driver units designed for optical/electrical triggering into the gate contact ring.

- Service‑friendly – Standard press‑pack handling; quick replacement in properly designed clamping assemblies.

- Traceability – ABB labeling supports lifecycle tracking and quality documentation.

Technical Specifications

| Brand / Model | ABB / 3BHL000392R0101 |

| Product Type | IGCT (Integrated Gate‑Commutated Thyristor) press‑pack module |

| HS Code | 8541.30 (Thyristors, diacs and triacs) |

| Power Requirements | Module is passive; associated gate driver typically supplied with 24 VDC |

| Signal I/O | Main anode/cathode power path; gate contact ring interface to dedicated driver unit |

| Communication Interfaces | None (power semiconductor device) |

| Installation Method | Press‑pack clamped between heat sinks; use specified clamping force per ABB guidelines |

| Cooling | Forced air or liquid‑cooled heat sink depending on converter stack design |

Application Fields

This IGCT module is commonly used in:

- Medium‑voltage AC drives (e.g., fan/pump trains, compressors, rolling mills, cement kilns)

- FACTS equipment such as STATCOM/SVC where fast, efficient switching is required

- Large rectifiers and DC links in marine propulsion and mining conveyors

- Grid‑tied power quality systems and regenerative drives in heavy industry

One thing I appreciate is how IGCTs handle repetitive overloads in real plants—many maintenance teams report consistent thermal behavior shift‑to‑shift. A utilities customer told me they swapped a failed device during a planned outage and immediately saw a few degrees lower heat‑sink temperature under the same load profile, which matches what we typically see with a clean clamping stack and fresh thermal compound.

Advantages & Value (Procurement View)

- Reliability – Press‑pack design resists bond‑wire fatigue issues you get with some plastic modules.

- Compatibility – Fit‑for‑purpose in ABB converter stacks that specify IGCT devices, minimizing retrofit work.

- Efficiency – Lower conduction and switching losses can translate into measurable energy savings over time.

- Predictable serviceability – Straightforward replacement with calibrated clamping tools shortens downtime.

- Documentation & traceability – Supports quality audits and long‑term asset management.

Installation & Maintenance

- Panel/Cabinet – Use a clean, ventilated MV drive cabinet; maintain adequate airflow or coolant flow to the heat sink.

- Clamping – Apply the manufacturer‑specified clamping force with a calibrated press or disc‑spring assembly; check heat‑sink flatness and surface finish.

- Wiring – Keep busbar paths short and symmetrical; verify snubber and gate driver connections before energizing.

- Safety – De‑energize, discharge DC link capacitors, and follow ESD precautions; avoid touching the gate contact ring.

- Routine care – Periodically inspect for hot spots (IR scan), re‑torque busbars if specified, clean dust, and verify driver health; firmware checks apply to the gate driver unit rather than the module.

- Commissioning – Perform gate signal integrity checks and confirm protective settings (dV/dt, current limits) on the converter controller.

Recommended Supporting Components

- ABB IGCT Gate Driver Unit (GDU) – Provides the required drive energy and protection for the gate contact ring.

- Snubber capacitor/resistor assemblies – To manage dV/dt and transient energy in the converter leg.

- Calibrated clamping set and disc springs – Ensures correct press‑pack force and long‑term stability.

- Heat sink or liquid cold plate – Sized for the loss profile of the specific duty cycle.

- Thermal interface material (TIM) – High‑quality grease or pads to maintain low thermal resistance.

Quality & Certifications

- Manufactured under ABB’s quality system (ISO 9001)

- RoHS and REACH compliant in most cases for semiconductor components

- Component‑level products typically do not carry CE/UL markings (system‑level compliance handled by the drive/converter)

- Manufacturer’s warranty: typically 12 months when purchased new; supplied units covered by our 365‑day warranty

If you’re replacing a failed device or building a maintenance kit, share your converter rating and gate driver part numbers. Matching the IGCT to the installed driver and clamping geometry is, in most cases, the quickest way to ensure drop‑in compatibility and avoid commissioning surprises.

Reviews

There are no reviews yet.