Description

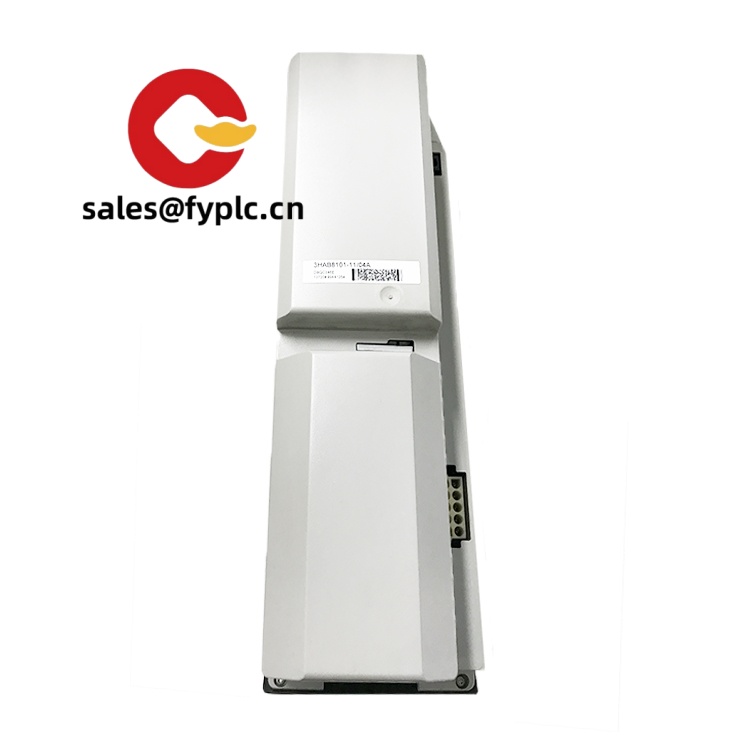

ABB 3HAB8101-18/09A – High-Performance Servo Drive for Precision Motion Control

If you’re running automated assembly lines or robotics cells that demand tight motion accuracy, the ABB 3HAB8101-18/09A typically stands out as a solid pick. It’s part of ABB’s well-regarded IRC5 servo drive family, commonly used in robotic arms like the IRB 2400 and IRB 4400 series. From my experience, this drive delivers consistent torque response and smooth commutation, which matters when you’re trying to minimize cycle time variance on packaging or welding applications.

Key Features

- Integrated feedback handling: Supports resolver and encoder inputs, so it works with a range of ABB servo motors without needing external conversion modules.

- Modular diagnostics: LED indicators for overvoltage, overheating, and communication faults make troubleshooting faster—especially useful during unplanned downtime.

- Dynamic current control: Delivers up to 18A peak output, suitable for medium-duty robotic joints that require quick acceleration without thermal throttling.

- IRC5 platform compatibility: Plugs directly into standard IRC5 cabinets, reducing integration time. One thing I appreciate is how it shares firmware updates with other drives in the system via RobotWare.

- Regenerative braking support: In many cases, this helps reduce heat buildup in multi-axis systems by feeding energy back into the DC link instead of dissipating it as waste heat.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB / 3HAB8101-18/09A |

| HS Code | 85371090 |

| Power Requirements | DC 50–80 V (from IRC5 main supply) |

| Peak Output Current | 18 A |

| Operating Temperature | 0 °C to +45 °C |

| Signal I/O Types | Resolver feedback, digital enable/disable, fault relay |

| Communication Interface | DSQC interface via backplane (no Ethernet/IP standalone) |

| Installation Method | DIN rail mount in IRC5 cabinet (standard ABB modular layout) |

| Dimensions & Weight | Approx. 120 x 250 x 70 mm, 1.4 kg |

Application Fields

This drive shows up most often in automotive manufacturing plants—particularly on spot welding robots where timing precision and fault resilience are non-negotiable. But it also sees use in material handling setups using IRB 6600 arms, and occasionally in dispensing systems where speed modulation affects adhesive consistency. You might notice that facilities with mixed generations of IRC5 controllers tend to stock spares of this model due to its broad motor compatibility.

Advantages & Value

Procurement teams usually favor this unit because it reduces mean time to repair (MTTR). Since it uses standardized mounting and cabling, swapping one out takes under 20 minutes in most cases. There’s also value in firmware traceability—each unit logs runtime hours and fault codes, which helps with predictive maintenance planning. While not the cheapest servo drive on the market, its reliability cuts down on unexpected production stops, which ultimately protects your OEE metrics.

Installation & Maintenance

Make sure the cabinet meets IP54 standards and has adequate airflow—this drive doesn’t have a fan but relies on convection cooling. Avoid stacking multiple high-load drives adjacent without spacing. When wiring, double-check the motor phase sequence and shield grounding; reversed phases can damage the connected motor during initial power-up. For maintenance, clean dust from vents quarterly and verify firmware alignment across all drives during scheduled robot backups. Calibration isn’t user-serviceable, but monitoring current ripple through RobotStudio can hint at aging components before failure occurs.

Quality & Certifications

The 3HAB8101-18/09A carries CE, UL, and RoHS compliance marks, and is built under ISO 9001-controlled processes. Each unit undergoes burn-in testing before shipment. The warranty period is 365 days, covering defects in materials and workmanship—though misuse (like operating above 45°C or incorrect input voltage) typically voids coverage. We don’t cover labor costs for onsite replacement, but technical support is available to guide diagnostics remotely.

Order Notes: Delivery takes about one week for in-stock units; no more than a month if shipped from regional inventory. Payment requires 50% upfront, with full balance due before dispatch. We ship via FedEx, UPS, or DHL depending on destination and urgency.

Reviews

There are no reviews yet.