Description

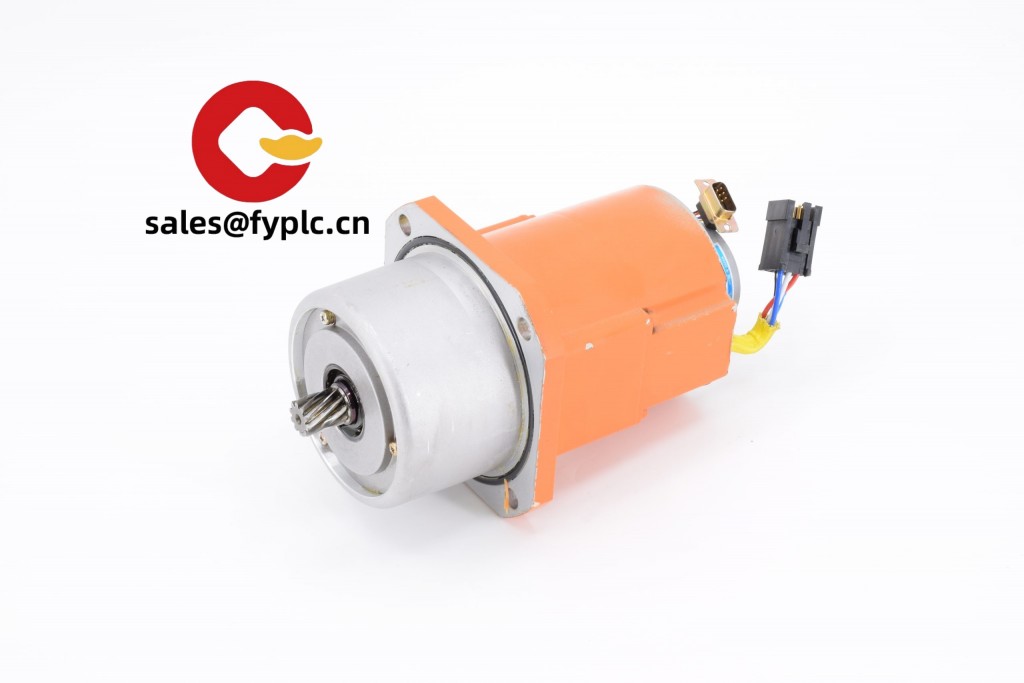

ABB 3HAC14550-2/09A – Servo Drive Module for Precision Motion Control

If you’re working on robotic motion systems—especially in automotive assembly or precision manufacturing—you’ve likely come across the ABB 3HAC14550-2/09A. It’s a servo drive module designed specifically for ABB’s IRB robot series, and from my experience, it tends to be one of those components that quietly keeps production lines running without drama. One thing I appreciate is how well it integrates with other drives in the 3HAC family, which simplifies spares management across multiple stations.

Key Features

- High-current output: Delivers up to 9 A continuous current, suitable for driving medium-sized servo motors used in articulated robot arms.

- Digital signal processing: Built-in DSP architecture ensures fast response times and precise torque control during dynamic movements.

- Integrated safety functions: Supports STO (Safe Torque Off), which typically meets SIL 2 requirements when properly wired—helpful for reducing risk in collaborative environments.

- Modular design: Slides into standard ABB cabinet racks and connects via backplane, minimizing wiring complexity during installation or replacement.

- Firmware traceability: Each unit logs firmware version and calibration data, making troubleshooting more efficient during maintenance cycles.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB / 3HAC14550-2/09A |

| HS Code | 8537.10.00 (Control panels for industrial automation equipment) |

| Power Requirements | DC link voltage: 300–400 V DC (typically derived from three-phase 200–240 V AC supply via rectifier stage) |

| Dimensions & Weight | Approx. 120 mm (W) × 200 mm (H) × 150 mm (D), ~1.8 kg |

| Operating Temperature | 0°C to +45°C (derating may apply above 40°C) |

| Signal I/O Types | Digital inputs for enable, fault reset; analog feedback input for motor current sensing |

| Communication Interfaces | Fieldbus via internal CAN bus backbone; compatible with ABB RobotWare communication protocols |

| Installation Method | DIN rail or panel mount within IP54-rated control cabinet; uses front-panel screw terminals and rear backplane connection |

Application Fields

This drive is most commonly found in robotic welding cells, material handling lines, and automated dispensing systems. In many cases, it powers axis drives in six-axis robots like the IRB 1600 or IRB 2600. You might notice that plants using centralized DC bus architectures tend to favor this model due to its compatibility with shared power modules, which can reduce energy waste and cooling demands.

Advantages & Value

Procurement teams often highlight availability and interchangeability as key factors. Since ABB maintains long-term support for legacy models in this series, sourcing replacements isn’t usually a bottleneck. From a lifecycle cost standpoint, these drives tend to last 7–10 years under normal loads, assuming proper ventilation. There’s also value in consistency—plants with standardized ABB robotics benefit from reduced training and spare part sprawl.

Installation & Maintenance

Mount only in upright orientation inside a sealed cabinet meeting at least IP54 standards. Avoid placing near heat-generating components like transformers—the aluminum heatsink needs ambient airflow. When wiring, double-check grounding continuity between the drive chassis and cabinet frame to prevent noise interference. For maintenance, inspect terminal tightness every 12 months and verify firmware alignment across all drives after any system update. Cleaning should involve dry compressed air; never use solvents directly on circuit boards.

Quality & Certifications

Certified to CE, UL 508C, and RoHS standards. Complies with ISO 13849-1 for functional safety in control systems. The manufacturer typically offers a 365-day warranty against defects in materials and workmanship, provided environmental specs are followed and no unauthorized modifications were made.

Delivery takes about one week if in stock; otherwise, no more than a month. We require 50% upfront payment, with the balance due before shipment. Units ship via FedEx, UPS, or DHL depending on destination and urgency.

Reviews

There are no reviews yet.