Description

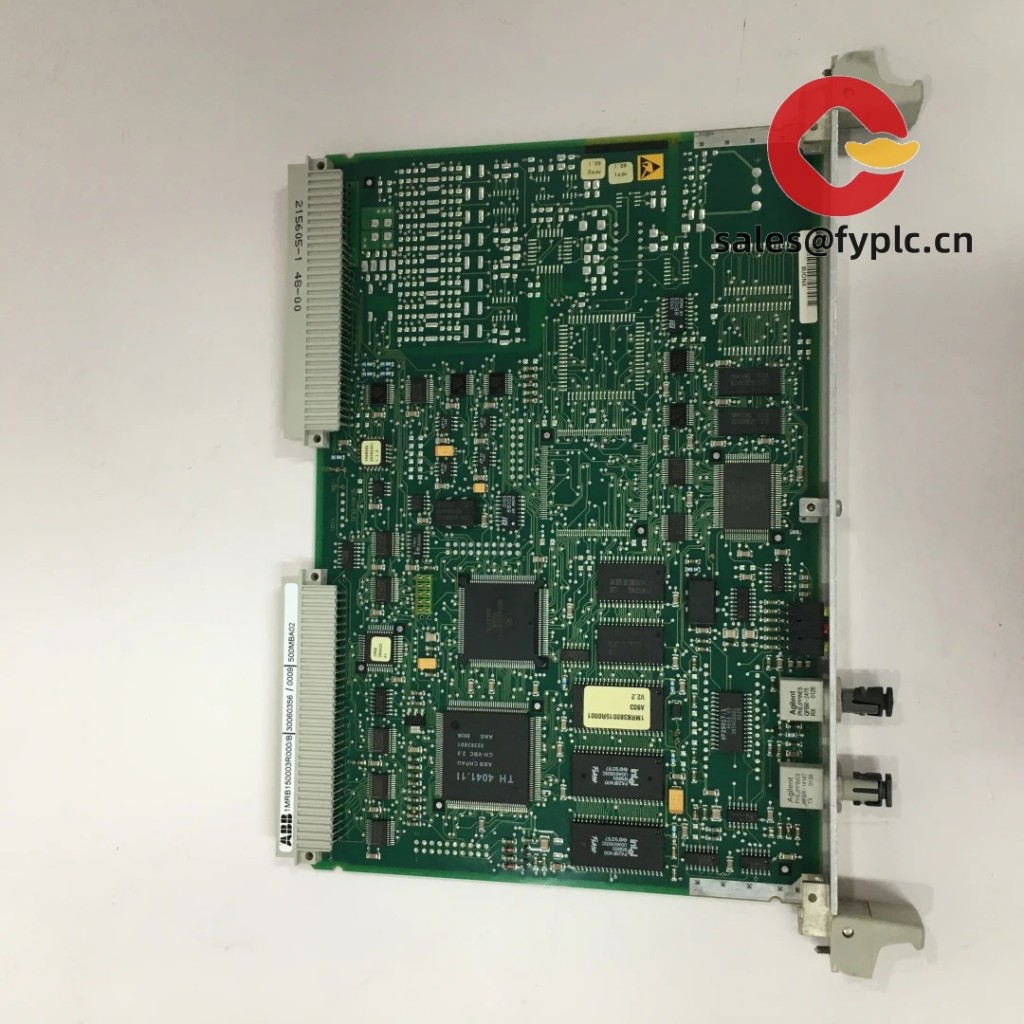

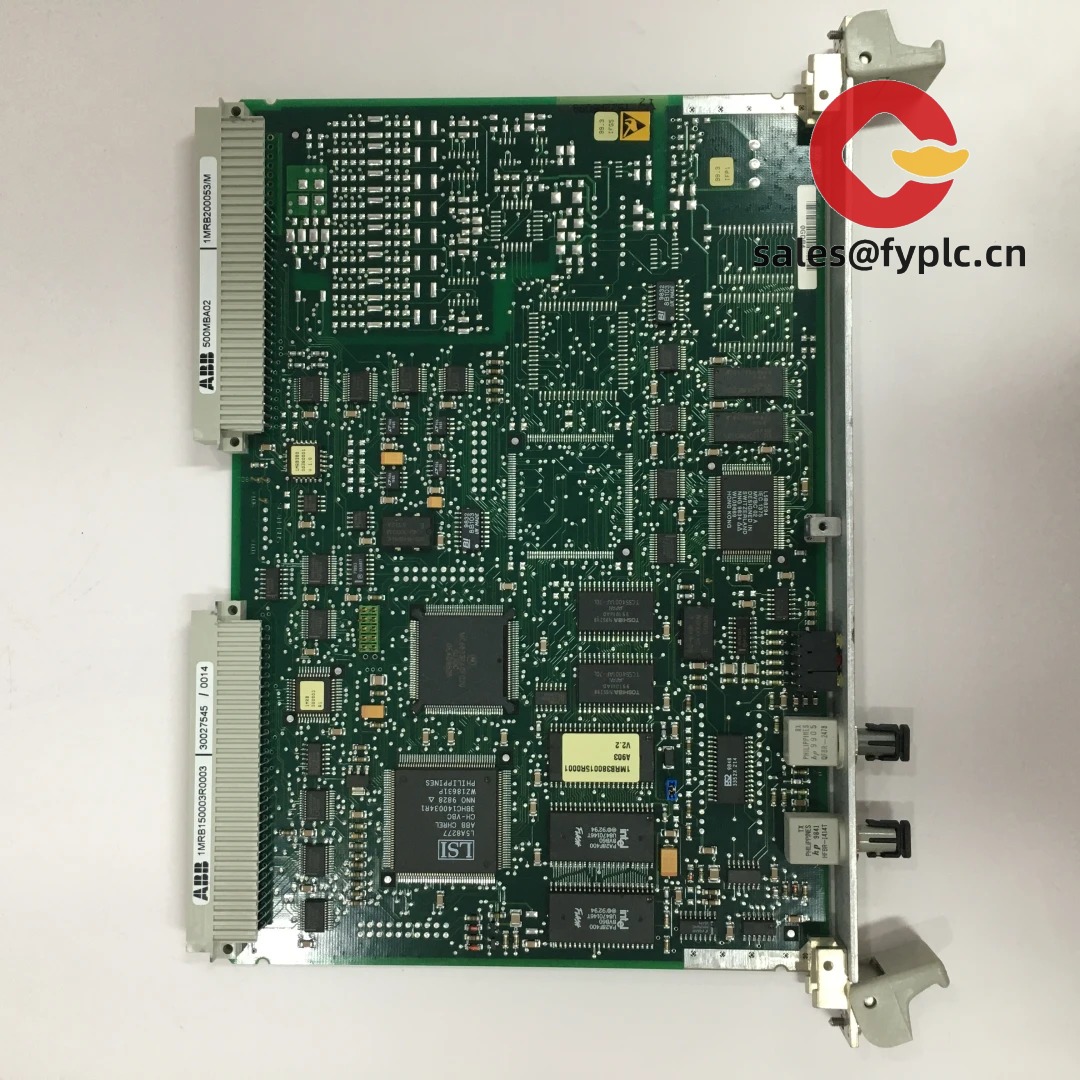

ABB 500MBA02 (Order Code: 1MRB150003R0003; Variant: 1MRB200053M) – Main Backplane/Adapter Board for ABB Industrial Drives

The ABB 500MBA02 with order code 1MRB150003R0003 (variant 1MRB200053M) acts as the internal backplane/adapter inside ABB drive cabinets, tying the CPU, I/O, and communication modules together. From my experience, when this piece starts aging you’ll typically see intermittent comms faults, delayed interlock updates, or I/O status that “flickers” under heat or vibration. One thing I appreciate is how the keyed connectors and standoff pattern support a clean, like-for-like swap—maintenance can slot it in during a short outage and get the line moving again.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment method: 50% advance payment; full payment for delivery

- Express delivery methods: FedEx / UPS / DHL

- Compatibility check: Share the drive nameplate and a clear photo of the board label; this typically locks the right revision on the first pass.

Key Features

- Main backplane interface – Links CPU, I/O and comms modules so control, status, and diagnostics stay synchronized.

- Drop-in replacement – Like-for-like module that minimizes wiring disturbance and parameter changes in most cases.

- Stability under load – Helps eliminate intermittent “comms lost” or inconsistent interlock updates caused by aged connectors or traces.

- Service-friendly layout – Keyed headers, labeled connectors, and accessible mounting points for quick swap-outs.

- Lifecycle extension – Keeps installed ABB drive systems productive without moving to a full cabinet retrofit.

Technical Specifications

| Brand / Model | ABB 500MBA02 (Order code: 1MRB150003R0003; Variant: 1MRB200053M) |

| HS Code | 8538.90 (Parts suitable for electrical control apparatus) |

| Power Requirements | Powered by the host drive’s LV rail; 24 VDC typical, low power consumption |

| Operating Temperature | Typically 0…55 °C when installed in a ventilated, non‑condensing cabinet |

| Signal Input/Output Types | Internal control/status lines via backplane/edge connectors; channel set depends on host drive configuration |

| Communication Interfaces | Internal drive bus interface; external fieldbus (e.g., PROFIBUS/PROFINET/Modbus) via separate ABB adapters when present |

| Installation Method | Plug‑in board mounted on standoffs/screws; keyed connectors prevent mis‑seating |

Application Fields

Typically found across ABB AC/DC drive systems in metals processing, paper & converting, mining conveyors, oil & gas pumps/compressors, cranes/hoists, and general process automation. A common scenario is a line that passes a cold start but throws random “communication fault” or lagging interlocks after heat soak—replacing 500MBA02 often stabilizes the internal backbone without touching PLC logic or motor wiring.

Advantages & Value

- Reliability – Restores steady internal bus operation, reducing nuisance trips and unscheduled stops.

- Compatibility – Intended for ABB drive families; we verify part labels, revision levels, and host type so it fits right the first time.

- Cost savings – Board-level maintenance is typically far cheaper than a cabinet retrofit and shortens recommissioning.

- Predictable downtime – Drop‑in mechanics and clear labeling keep the changeout inside a tight maintenance window.

- Technical support – Parameter backup guidance, revision matching, and post‑swap checks to keep risk low.

Installation & Maintenance

- Cabinet standards – Install in a clean, dry, ventilated enclosure (IEC/UL compliant). Keep ambient 0…55 °C; avoid condensation and conductive dust.

- Safety & isolation – Lockout/tagout, wait for DC bus discharge, verify zero energy before handling.

- ESD precautions – Use a wrist strap and handle by PCB edges; avoid touching component pins.

- Connections – Fully seat backplane/edge connectors; confirm PE bonding and proper cable strain relief.

- Commissioning checks – Validate DI/DO updates, interlock timing, and run a controlled speed ramp while monitoring alarms.

- Routine care – Annual dust cleaning, connector inspection/re‑seating, and event‑log review; align drive firmware per ABB guidance.

Quality & Certifications

- Used within CE‑conformant drive assemblies; the module forms part of the certified system.

- UL recognition typically applies at the complete drive assembly level.

- RoHS‑compliant components in many cases for ABB electronic spares.

- Manufactured under ISO 9001 quality systems at the OEM level.

- Warranty: 12 months (365 days) against functional defects under normal operation.

A maintenance lead at a strip mill told us a straight swap of this 500MBA02 variant cleared a sporadic “internal comms fault” that only appeared after weekend shutdowns. If you can send the drive type code and a clear photo of your current board label, we’ll confirm compatibility, reserve stock, and align shipment with your maintenance window.

Reviews

There are no reviews yet.