Description

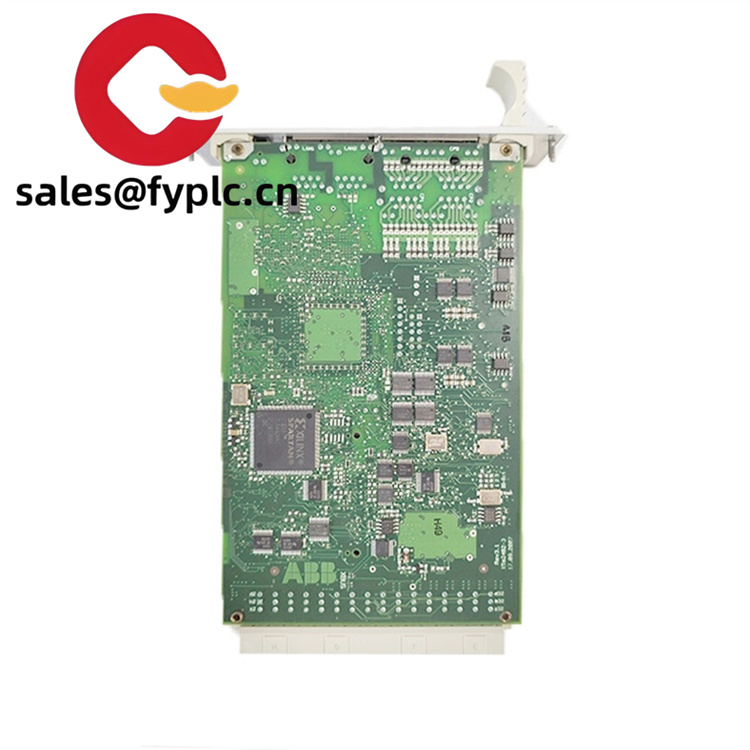

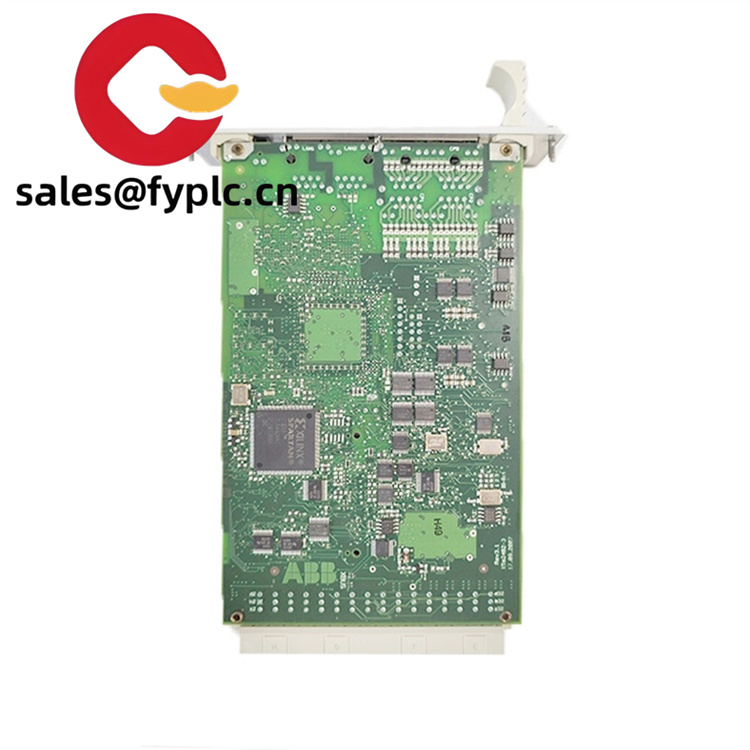

ABB 560CMU05 |Communication Module Central Control Processor

560CMU05

In the realm of industrial automation and control, the ABB 560CMU05 emerges as a pivotal component, designed to streamline operations and enhance the efficiency of complex industrial systems. Engineered with ABB’s renowned expertise, this module serves as a central control unit, facilitating seamless communication and precise coordination between various elements within an automation setup. Whether integrated into large – scale manufacturing plants, power generation facilities, or process industries, the ABB 560CMU05 plays a crucial role in ensuring smooth operation, real – time monitoring, and optimal performance of industrial processes.

| Label |

Specification |

| Model Number |

560CMU05 |

| Brand |

ABB |

| Type |

Central Control Module |

| Input Voltage |

24V DC |

| Operating Temp |

-20°C – 60°C |

| Communication Method |

Ethernet, Profibus, Modbus |

| Mounting |

DIN rail mounting |

| Weight |

[Specific weight as per product manual] |

| Certifications |

CE, UL, IEC compliant |

| Dimensions |

[Length]×[Width]×[Height] (mm) |

| IP Rating |

IP20 |

| Protocols Supported |

TCP/IP, UDP, and industry – standard automation protocols |

560CMU05

The ABB 560CMU05 stands out in real – world industrial environments due to its exceptional functional strengths and design advantages. This unit has been engineered to deliver lightning – fast processing speeds, allowing it to handle a vast amount of data in real – time. In a high – speed manufacturing line, for example, the 560CMU05 can quickly analyze sensor inputs, make split – second decisions, and adjust the production process to ensure quality and efficiency. Its resilience is also a key feature, as it can withstand electrical interference, vibrations, and temperature fluctuations commonly found in industrial settings.

Operators benefit from the 560CMU05‘s high level of interoperability. It can seamlessly integrate with a wide range of ABB and third – party devices, including sensors, actuators, and other control modules. This compatibility makes it easy to build and expand automation systems, reducing the complexity and cost of implementation. The module’s user – friendly interface simplifies configuration and maintenance, enabling technicians to quickly set up the system and troubleshoot any issues that may arise.

The ABB 560CMU05 is widely used in various industrial use cases, delivering significant value to different sectors. In power plants, it is often deployed in Supervisory Control and Data Acquisition (SCADA) systems. Here, the 560CMU05 monitors and controls critical processes such as power generation, transmission, and distribution. By providing real – time data and precise control, it helps optimize power output, improve grid stability, and reduce energy losses.

In the manufacturing industry, the 560CMU05 plays a vital role in factory automation. It can manage multiple production lines, coordinate the movement of robotic arms, and ensure the smooth flow of materials. For instance, in an automotive assembly plant, the ABB 560CMU05 can synchronize the operations of different machines, detect faults in real – time, and initiate corrective actions, thereby increasing productivity and reducing downtime.

- 560CMU06 – An advanced version with increased processing power and additional communication interfaces.

- 560CMU04 – A cost – effective alternative with similar basic functions, suitable for smaller – scale applications.

- PM866AK01 – A controller module that pairs perfectly with the 560CMU05 to enhance overall system performance.

- AI810 – An analog input module that can be integrated with the 560CMU05 for accurate data collection from sensors.

- DO810 – A digital output module that works in tandem with the 560CMU05 to control actuators and other devices.

-

560CMU05

Installing the ABB 560CMU05 requires careful attention to detail. When mounting it on the DIN rail, ensure that the rail is properly grounded and free from any debris. The module should be firmly attached to prevent vibrations from affecting its performance. When making electrical connections, follow the wiring diagrams provided in the product manual precisely. Use high – quality cables and connectors to ensure reliable power supply and signal transmission.

For long – term maintenance, regular inspections of the 560CMU05 are essential. Check the module for any signs of physical damage, such as cracks or loose connections, on a monthly basis. Monitor its operating temperature and status indicators regularly to detect potential issues early. Clean the module periodically to remove dust, which can accumulate over time and affect its performance. Additionally, it is advisable to update the module’s firmware as recommended by ABB to benefit from the latest features, security patches, and performance improvements.

Reviews

There are no reviews yet.