Description

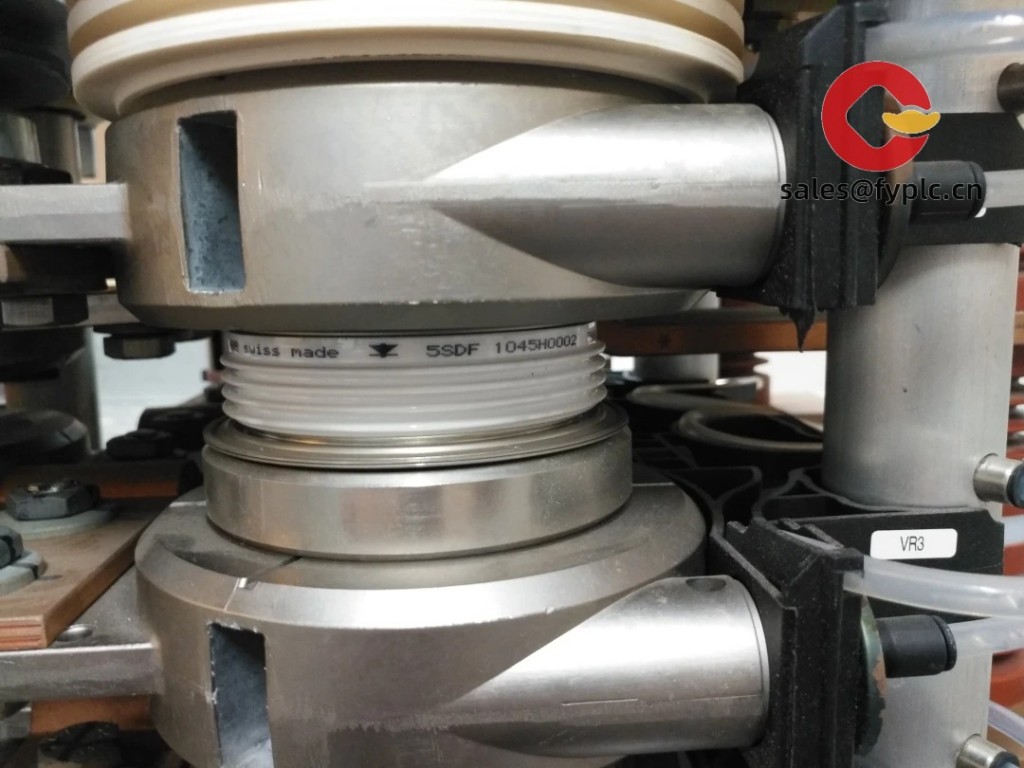

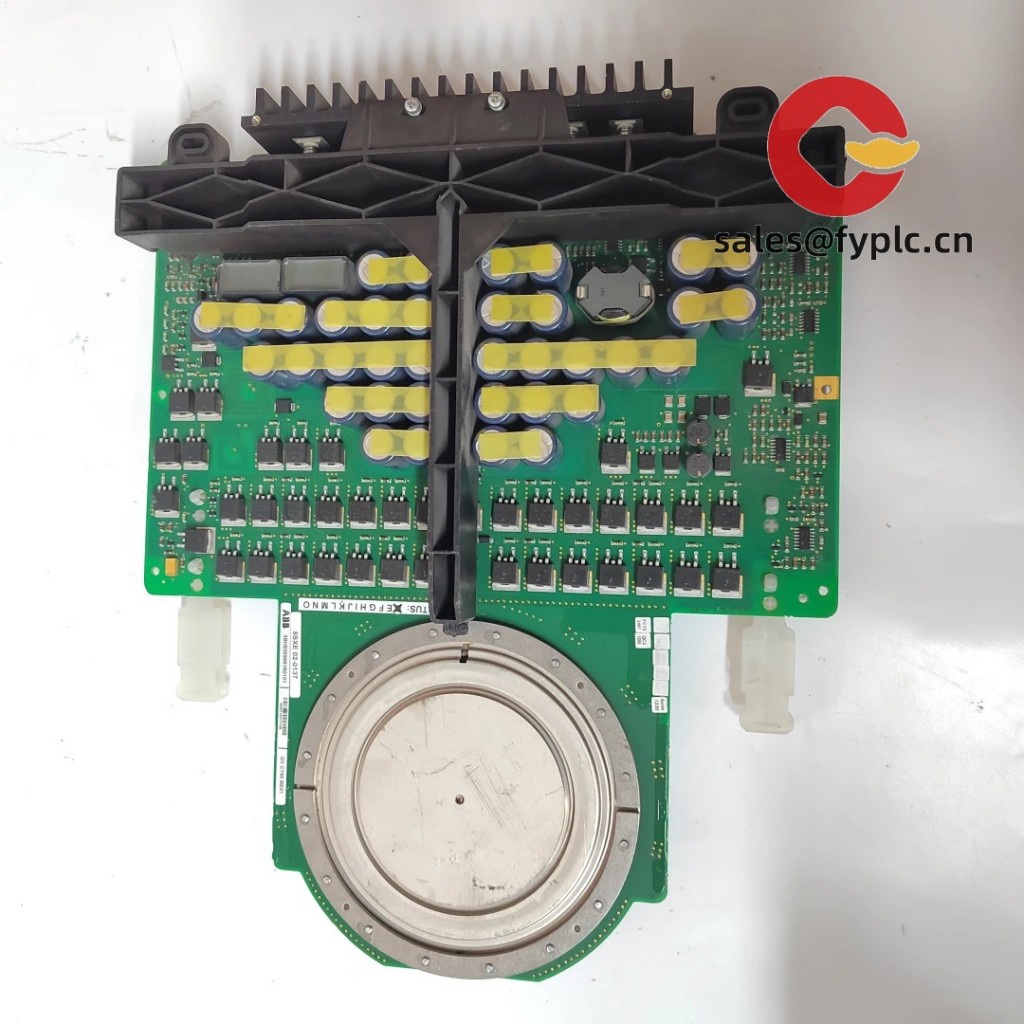

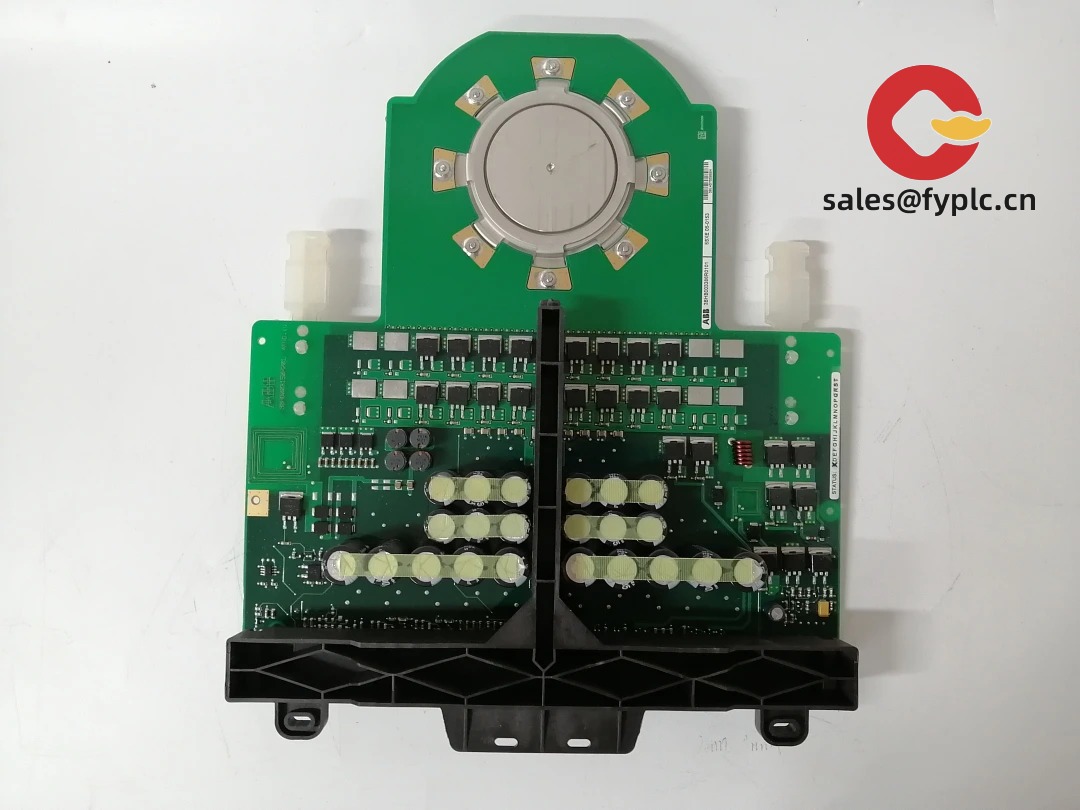

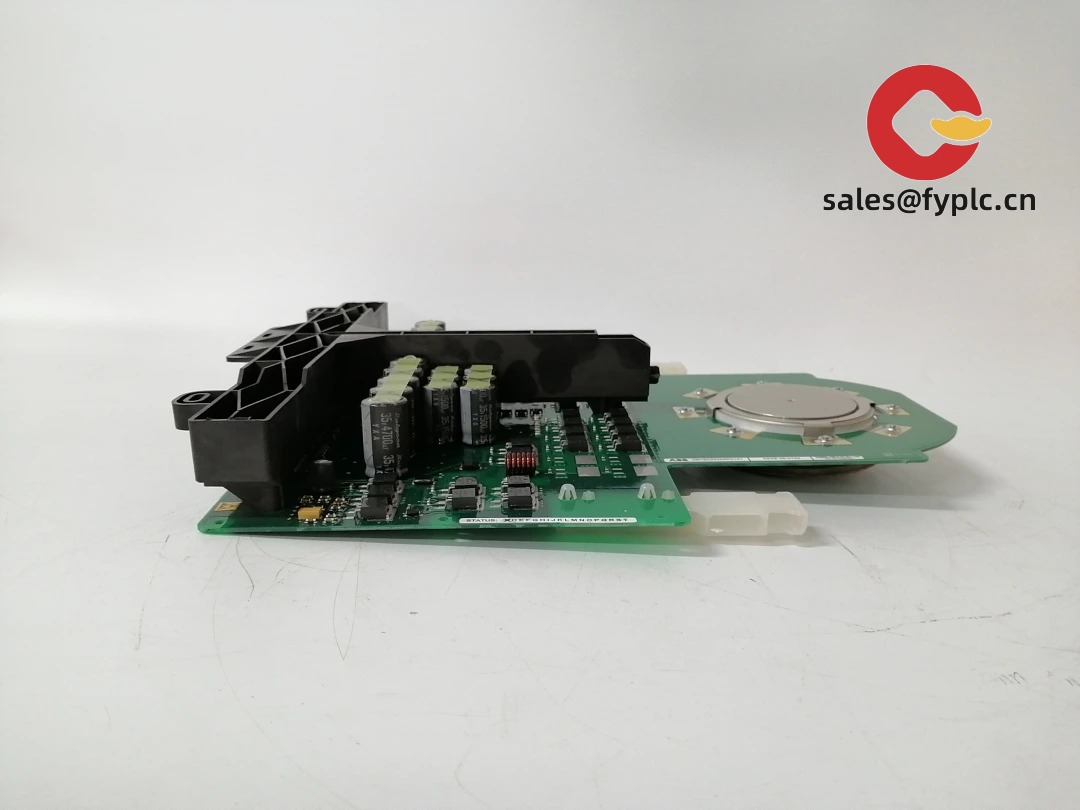

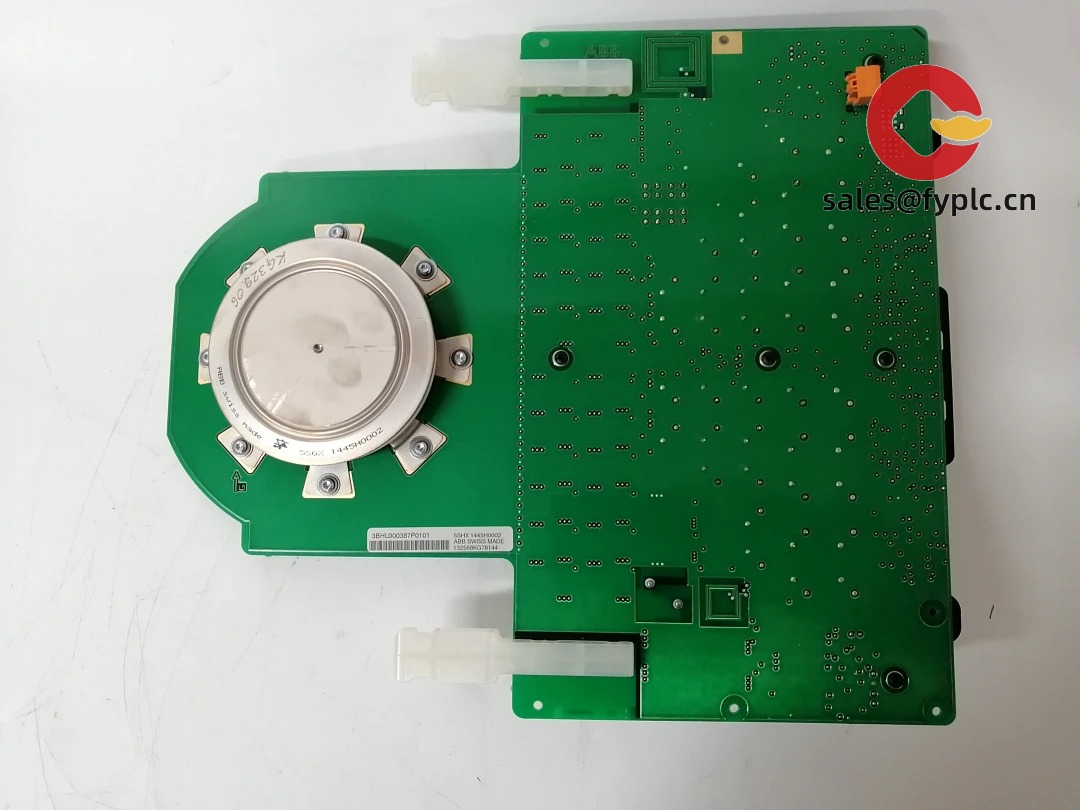

ABB 5SHX1445H0002 – 3BHL000387P0101 – IGCT Press‑Pack Device with Clamping/Mounting Assembly for Medium‑Voltage Drives

The ABB 5SHX1445H0002 is a press‑pack IGCT device, shown here with the associated assembly 3BHL000387P0101, typically used to mount and clamp the device correctly in a converter stack. From my experience, pairing the IGCT with the matching mechanical kit keeps clamping force, creepage distances, and thermal paths inside spec—key details that help stacks run cooler and avoid nuisance trips. You might notice that like‑for‑like swaps with this set usually let you keep the existing busbar geometry and snubber layout intact during a planned outage.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in‑stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

- Process: Confirm model and quantity → Proforma Invoice → Advance payment → Functional testing and packing → Final payment → Express shipment with tracking

Key Features

- Press‑pack IGCT device – Uniform pressure contact and excellent thermal cycling; no wire bonds to fatigue.

- Matched clamping/mounting hardware – 3BHL000387P0101 helps maintain the specified clamping force and isolation stack‑up.

- High‑power MV readiness – Suited for ABB converter legs where reliable turn‑off margins and clean commutation matter.

- Service‑friendly – Clamped construction makes like‑for‑like swaps straightforward during planned shutdowns.

- Stack compatibility – Typically fits existing busbars, snubbers, and insulators in ABB MV drive platforms.

Technical Specifications

| Brand / Model | ABB – 5SHX1445H0002 (IGCT) + 3BHL000387P0101 (mounting/clamping assembly) |

| HS Code | 854130 (Thyristors including gate‑turn‑off types / IGCT) |

| Power Requirements | Not applicable to the device (clamped semiconductor within the converter leg) |

| Dimensions & Weight | Press‑pack disk package; large‑diameter contact faces; kit weight typically 0.6–1.2 kg depending on hardware |

| Operating Temperature | Junction limits per ABB datasheet (often up to 125 °C); cabinet ambient typically 0…45 °C |

| Signal I/O Types | Anode/cathode press faces; gate/cathode control pins; optional NTC sense depending on build |

| Communication Interfaces | None (semiconductor device; interfaces to an external ABB gate unit) |

| Installation Method | Clamped between heat sinks using the specified force; connect to busbars and gate unit per ABB drawing |

Application Fields

Typically used in high‑power converter positions that demand robust switching and predictable thermal behavior:

- ABB medium‑voltage drives (commonly ACS1000 / ACS5000 / ACS6000 families)

- Industrial converters in metals, mining, cement, and chemical processing

- Stack refurbishments and lifecycle extensions during planned outages

- Critical spares programs to maintain N‑1 coverage

Advantages & Value

- Reliability: Press‑pack IGCTs typically ride through thermal cycles better, and matched hardware helps keep pressure within spec.

- Compatibility: Like‑for‑like replacement maintains existing busbars, snubbers, and cooling hardware in most cases.

- Downtime & cost: Predictable swap‑out during a short window; avoids re‑engineering a phase leg.

- Supportability: We can perform insulation checks and gate continuity tests and share results before shipping.

Installation & Maintenance

- Clamping & mechanics: Apply the OEM‑specified clamping force with a calibrated tool; ensure flat, clean heat‑sink faces and correct insulator stack‑up.

- Gate connections: Keep gate/emitter leads short and symmetrical; verify gate resistor values match your drive documentation.

- Safety: Lockout/tagout; allow the DC link to fully discharge; follow ESD precautions when handling the device and gate wiring.

- Commissioning: Scope a low‑load start to confirm clean turn‑off behavior; review snubber condition and thermal path.

- Routine care: Periodic thermal imaging under load, re‑torque checks after first heat cycles (if specified), and dust/airflow housekeeping.

Quality & Certifications

- Quality system: Manufactured under ISO 9001 processes (typical for ABB power semiconductors and assemblies).

- Compliance: Intended for use inside CE/UL‑listed converter systems; RoHS status may vary by production year.

- Warranty: 365‑day warranty from shipment date.

Supporting Components You Might Also Need

- Gate units (3BHB‑series) compatible with your IGCT rating

- Snubber capacitors/resistors matched to the stack position

- Fiber‑optic links and transceivers for the drive bay (if driver upgrades are planned)

- Cooling hardware and insulation kits for full position refresh

Share your drive type, stack position, and current gate unit details, and we’ll verify interchangeability for 5SHX1445H0002 with 3BHL000387P0101 and prepare a brief pre‑shipment test and inspection record.

Reviews

There are no reviews yet.