Description

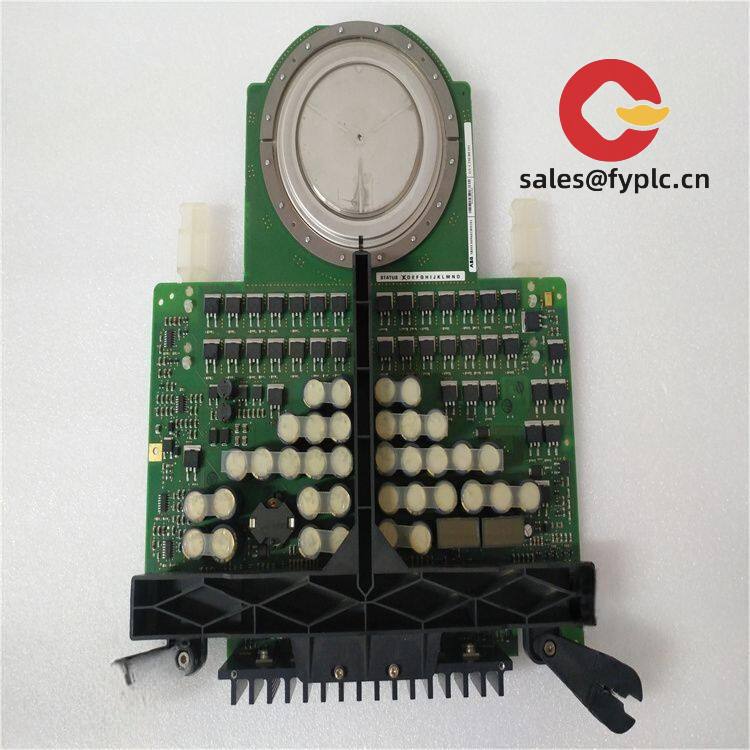

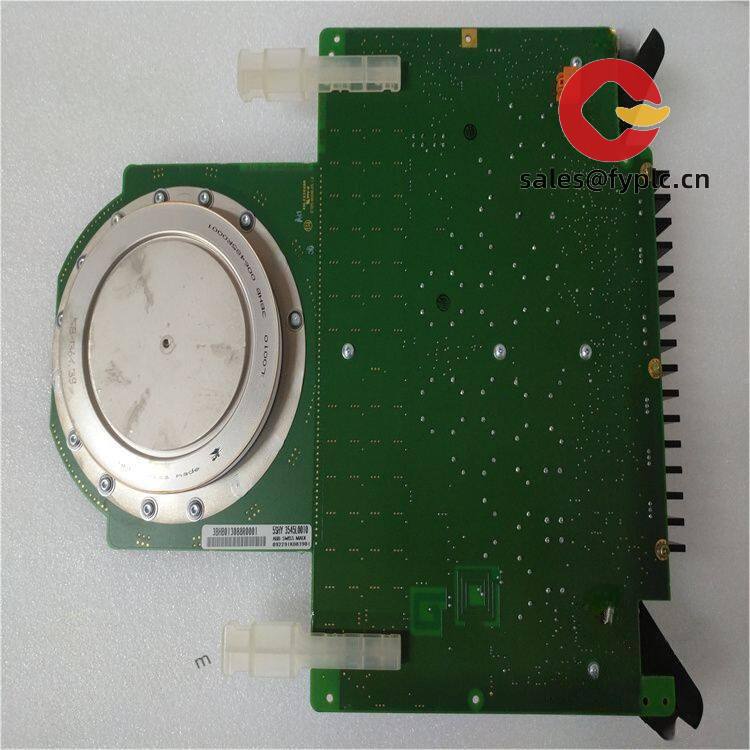

ABB 5SHX1960L0005 IGCT Gate Unit – Reliable, fast switching control for medium-voltage power converters

The ABB 5SHX1960L0005 is part of ABB’s 5SHX gate-unit family typically used to drive ABB IGCTs (Integrated Gate-Commutated Thyristors) in high-power converters. From my experience, this series pairs well with ABB 4.5 kV and 6.5 kV IGCT devices (5SHY family), giving you clean turn-on/turn-off behavior, strong short-circuit handling, and the kind of timing accuracy you want in MV drives, STATCOMs, and traction inverters. One thing I appreciate is the straightforward fiber‑optic triggering and robust interlock logic—it keeps integration clean and predictable in most control architectures.

Our Order Process & Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Dedicated IGCT driver – Designed to mate with ABB IGCTs for fast, reliable gate control and low switching losses.

- Fiber‑optic firing interface – Noise‑immune triggering and status feedback, which in many cases simplifies EMC and cabling in large cabinets.

- Integrated protection logic – Typically includes interlock, fault status output, and controlled turn‑off to protect the semiconductor during abnormal events.

- High di/dt capability – Optimized gate drive to support the IGCT’s fast commutation characteristics in demanding converter stages.

- Serviceable design – Field-replaceable gate unit concept; you can swap a GDU without disturbing the power stack more than necessary.

- Proven in MV platforms – Commonly seen in medium‑voltage drives, wind converters, STATCOMs, and rail traction where uptime is critical.

Technical Specifications

| Brand / Model | ABB 5SHX1960L0005 |

| Product Type | IGCT Gate Unit (driver) for ABB IGCT power semiconductors |

| HS Code | 8538.90 (Parts suitable for switching/control apparatus; commonly used for gate driver units) |

| Power Requirements | Typically 24 VDC auxiliary supply (industrial range, e.g., 18–30 VDC); low steady‑state power consumption |

| Operating Temperature | Typically −25 °C to +70 °C (application dependent; follow ABB datasheet for exact limits) |

| Signal I/O Types | Fiber‑optic control input/output, hardware interlock/status contacts (varies by stack design) |

| Communication Interfaces | Fiber‑optic trigger interface; no fieldbus on the gate unit itself |

| Installation Method | Direct mounting on the compatible ABB IGCT with specified clamping; auxiliary power via terminal/plug; fiber ports to control |

Application Fields

You’ll typically see the 5SHX1960L0005 in:

- Medium‑voltage drives for compressors, pumps, and fans

- Reactive power compensation such as STATCOM and SVC systems

- Rail traction converters and marine propulsion drives

- Wind and photovoltaic central inverters using IGCT stacks

- Industrial UPS and energy storage converters with high cycling demands

Advantages & Value

- System reliability – Matched ABB driver-to-device behavior helps reduce nuisance trips and thermal stress on the IGCT.

- Compatibility – Seamless pairing with ABB IGCTs (5SHY series) and fiber‑optic control schemes used in many MV platforms.

- Lifecycle cost – Stable availability and serviceable design can cut downtime costs compared with custom driver boards.

- Engineering support – ABB documentation and established application notes speed up commissioning and troubleshooting.

A maintenance lead from a steel mill told us the swap time “went from hours to under 45 minutes” after standardizing on ABB gate units across their IGCT stacks—seems to be a common theme when spares are aligned.

Installation & Maintenance

- Panel and cabinet – Use an IP54 or better cabinet in dusty/humid areas; maintain clear airflow around the power stack. Keep fiber bends within the recommended radius.

- Wiring and power – Provide a clean, regulated 24 VDC auxiliary supply with proper grounding. Route auxiliary and fiber separately from high‑dv/dt busbars.

- Mounting – Follow ABB torque and clamping instructions to ensure correct pressure and alignment on the IGCT housing.

- Safety – Lockout/tagout the DC link; discharge capacitors fully. Verify fiber polarity and interlock chain before energizing.

- Routine care – Inspect connectors quarterly, check fiber cleanliness, and review thermal logs. Firmware/config (if applicable) should be kept at the recommended revision.

- Calibration/health – Periodically validate turn‑off energy and gate current waveforms during service windows; abnormal signatures often indicate upstream issues.

Quality & Certifications

- Manufactured under ISO 9001 quality systems

- CE compliance for applicable EMC/Low Voltage aspects at the assembly level

- RoHS compliant materials, typical for ABB semiconductor assemblies

- Warranty: 365 days

Related Components (for a complete stack)

- ABB IGCT devices: 5SHY series (e.g., 4.5 kV / 6.5 kV classes)

- Fiber‑optic transmitter/receiver modules and cables

- Snubber capacitors and clamp hardware specified for the target IGCT

- Auxiliary 24 VDC industrial power supply and interlock relays

If you need a cross‑check on compatibility with your exact IGCT part number or a recommended spares list, share your converter topology and we’ll map the gate units, fibers, and accessories accordingly. You might notice that having matched pairs (IGCT + 5SHX gate unit) typically shortens commissioning time and reduces parameter tweaking.

Reviews

There are no reviews yet.