Description

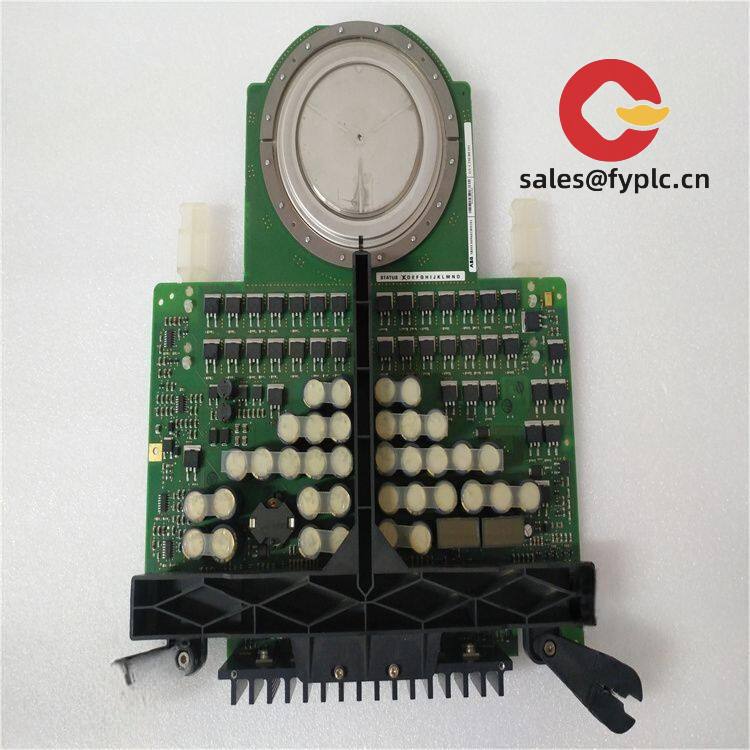

ABB 5SHY4045L0002 IGCT – High‑power press‑pack device for medium‑voltage drives and converters

The ABB 5SHY4045L0002 is an IGCT (Integrated Gate-Commutated Thyristor) designed for demanding, high‑power switching in medium‑voltage applications. From my experience, this model sits in the sweet spot for retrofit projects in steel rolling mills, large fan/pump drives, and FACTS/STATCOM modules where long service life and predictable thermal behavior matter more than chasing the latest buzzword. You might notice that IGCTs typically deliver lower conduction losses and a fail‑safe press‑pack structure, which, in many cases, translates to fewer unplanned shutdowns and easier root‑cause analysis.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days coverage.

- Delivery time: 1 week if in stock; no more than one month at the latest.

- Payment: 50% advance payment; full payment before delivery.

- Express delivery: FedEx, UPS, DHL.

- Pre‑shipment checks: Visual inspection, serial/lot verification, and basic packaging integrity tests.

Key Features

- Press‑pack reliability: Metal‑ceramic, pressure‑contact design; typically fails to a short for safer protection coordination.

- High current and voltage class: Engineered for medium‑voltage converters; suitable for MV drives, static VAR equipment, and grid converters.

- Low conduction losses: IGCT conduction behavior often beats large IGBT stacks at high current, lowering steady‑state losses.

- Fast turn‑off with robust dv/dt: The integrated gate concept minimizes loop inductance, improving switching stability.

- Thermal stability: Press‑pack face-to-face mounting gives consistent thermal paths and straightforward heat‑sink interface.

- Serviceability: Replaceable device with no solder fatigue concerns; clamped assembly simplifies overhaul intervals.

- Long lifecycle support: ABB’s IGCT line has a strong track record in 24/7 industrial duty cycles.

Technical Specifications

| Brand / Model | ABB 5SHY4045L0002 |

| Product Type | IGCT (Integrated Gate‑Commutated Thyristor), press‑pack semiconductor device |

| HS Code | 8541.30 (Thyristors, diacs, triacs; non‑photosensitive) |

| Power Requirements | N/A for the device itself (passive). Requires a compatible IGCT gate unit for drive power and control. |

| Signal I/O | Main terminals: Anode/Cathode (press‑pack). Control: Gate/Cathode via gate unit connection. |

| Communication Interfaces | Not applicable to the device; fiber‑optic/electrical interfaces usually reside on the external gate unit. |

| Installation Method | Press‑pack clamping between heat sinks with controlled force; clean, flat contact surfaces required. |

| Operating Temperature | Per ABB datasheet; storage typically −40°C to +125°C. Observe device‑specific junction limits and derating curves. |

| Dimensions & Weight | Press‑pack disc format. Refer to the ABB mechanical drawing for exact diameter, height, and clamping area. |

Application Fields

- Medium‑voltage AC drives for compressors, pumps, and fans in oil & gas, mining, and water utilities.

- Steel and metals rolling mills where high current and regenerative operation are routine.

- FACTS/STATCOM and reactive power compensation systems.

- Traction power converters and heavy industrial rectifiers.

- High‑power test benches and energy storage converters (MV front‑ends).

A maintenance engineer at a cement plant told us the switch from older GTO stacks to an IGCT stage cut thermal cycling failures noticeably—mostly because the press‑pack design spreads heat more uniformly and the gate unit keeps turn‑off under tight control.

Advantages & Value

- Lifecycle costs: Lower conduction losses and fewer board‑level parts compared with large IGBT cascades can reduce operating expenses.

- Reliability under stress: Press‑pack contact avoids bond‑wire fatigue; typically better for cyclic thermal loading.

- Compatibility: Works with ABB IGCT gate units and standard MV converter topologies; straightforward drop‑in for many legacy ABB designs.

- Supply continuity: ABB’s long‑running IGCT platform supports spares and field retrofits in many cases.

- Technical support: We can share clamping torque ranges, thermal interface guidance, and gate‑unit selection notes to shorten your commissioning window.

Installation & Maintenance

- Cabinet & mechanical: Use a rigid heat‑sink stack (EN/IEC panel standards) with verified flatness; apply the specified clamping force using calibrated hardware.

- Thermal interface: Clean, lint‑free surfaces; apply approved thermal compound sparingly; avoid particle contamination.

- Wiring & gate unit: Keep the gate loop short and low‑inductance; route the gate‑unit power and fiber/electrical trigger per ABB layout practices.

- EMC & creepage: Maintain clearances for MV; add snubbers and dv/dt control components as recommended by ABB.

- Safety: De‑energize and discharge DC‑link capacitors before service; observe ESD precautions when handling the device and gate unit.

- Routine maintenance: Inspect clamping hardware torque after thermal cycles; clean dust from heat sinks; verify gate‑unit health, logs, and firmware (where applicable).

- Spares strategy: Stock one device and a matched gate unit per converter leg for time‑critical assets—this typically cuts MTTR significantly.

Quality & Certifications

- Manufactured under ISO 9001 and ISO 14001 quality and environmental systems (ABB facilities).

- RoHS compliant component, according to typical ABB semiconductor declarations.

- Device‑level CE/UL marking is generally not applicable to discrete semiconductors; system conformity depends on the complete converter.

- Standard ABB warranty terms; we provide 365‑day coverage on supplied units.

Helpful Complementary Items

- IGCT Gate Unit (GDU): Matched ABB gate unit for the device’s voltage/current class; provides drive power, protection logic, and (often) fiber‑optic interface.

- Clamping set & insulators: Calibrated studs, load spreaders, and insulator stacks to achieve the specified press force.

- Snubber network: RC or RCD snubbers to manage dv/dt and transient energy, improving device longevity.

- Heat‑sink assembly: Verified flatness and thermal resistance; optional liquid‑cooling plates for high duty cycles.

If you’re matching this ABB 5SHY4045L0002 to an existing converter, share your DC‑link voltage, per‑device current, switching frequency, and available clamping hardware. One thing I appreciate is how a little information upfront usually avoids weeks of iteration when selecting the gate unit and snubber values.

Reviews

There are no reviews yet.