Description

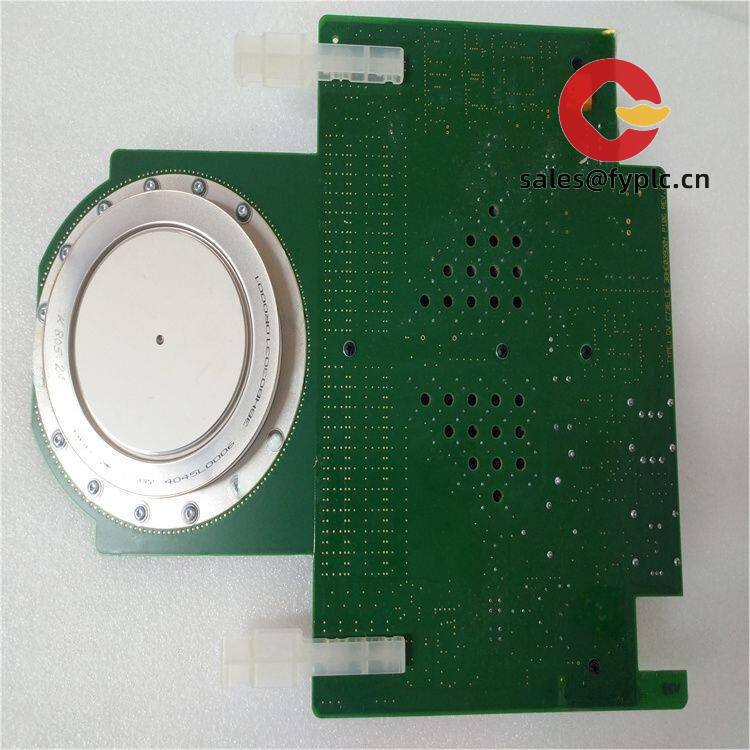

ABB 5SHY45L4520 IGCT Module – Reliable high-power switching for medium-voltage converters

The ABB 5SHY45L4520 is an IGCT (Integrated Gate-Commutated Thyristor) press-pack device built for heavy-duty power conversion. From my experience, this series is typically selected when engineers need fast turn-off capability with very low conduction losses at high current levels—think medium-voltage drives, STATCOM/SVC, and traction where downtime is expensive and thermal headroom really matters. You might notice that it drops into existing ABB press-pack stacks with standard clamping hardware, making retrofit projects far less painful.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance; full payment before delivery

- Express delivery: FedEx, UPS, DHL

- Traceability: Factory-sealed packaging with lot/serial details when provided by the manufacturer

Key Features

- Press-pack IGCT design: Metal-ceramic package for uniform current distribution and high surge robustness.

- Fast turn-off capability: Enables high-power PWM topologies with reduced switching losses compared to classic GTOs.

- Low conduction loss: In many cases, lower on-state losses than IGBT modules at comparable power levels.

- High reliability in MV systems: Favored in drives, traction, and FACTS where thermal cycling and fault tolerance are critical.

- Gate-unit compatible: Works with dedicated ABB IGCT gate units for controlled turn-on/turn-off and diagnostics.

- Service-friendly: Press-pack mounting makes stack replacement straightforward, typically without rework of busbars.

Technical Specifications

| Brand / Model | ABB 5SHY45L4520 |

| Device Type | Press-pack IGCT (Integrated Gate-Commutated Thyristor) |

| HS Code | 854129 (Thyristors, other) |

| Power Requirements | N/A (semiconductor device; driven by external gate unit) |

| Operating Temperature | Junction ratings per ABB datasheet; typically suitable for MV converter environments |

| Signal I/O | Main terminals: Anode/Cathode; Control: Gate to Cathode auxiliary connection |

| Communication Interfaces | None (controlled via dedicated gate unit) |

| Installation Method | Press-pack clamped between heat sinks; calibrated axial clamping force per ABB specification |

| Dimensions & Weight | Press-pack outline; refer to ABB drawing for diameter, height, and mass |

Application Fields

- Medium-voltage drives for mining, cement, oil & gas compressors, and marine propulsion

- FACTS/Utility systems: STATCOM, SVC, and grid-tied VAR compensation

- Traction propulsion and auxiliary converters

- Wind and industrial power converters where high current and reliability are key

- High-power test benches and pulse power supplies

Advantages & Value

- Reliability under stress: Press-pack architecture handles thermal and electrical cycling better than many module styles.

- Compatibility: Fits established ABB IGCT stacks and gate units, typically reducing engineering effort.

- Operational efficiency: Lower conduction losses can translate into cooler operation or headroom for overloads.

- Lifecycle support: We help match gate units, snubbers, clamps, and thermal hardware to shorten commissioning time.

- Risk reduction: Sourced from traceable channels with inspection on arrival; DOA replacement is straightforward.

One thing I appreciate is how maintenance teams can swap a press-pack IGCT in a stack within a planned stop. A customer in a rolling mill application mentioned they saw fewer nuisance trips after moving from legacy GTOs to this IGCT family—seems to be the cleaner turn-off behavior and tighter gate control.

Installation & Maintenance

- Cabinet & environment: Install in a clean, dry cabinet meeting industrial MV standards; ensure adequate ventilation or liquid-cooled heat sinks.

- Clamping force: Use a calibrated press system to apply the axial clamping force specified by ABB; verify planarity and surface cleanliness.

- Wiring: Keep gate-cathode leads short and shielded as recommended by the gate unit manual; observe creepage/clearance for MV.

- Thermal interface: Apply approved contact foil or grease if specified; check heat sink flatness and roughness.

- Safety: Lock-out/tag-out, discharge DC-link capacitors, and confirm isolation before handling.

- Routine checks: Inspect stack clamping torque, clean dust paths, verify gate unit health, and update firmware where applicable.

- Commissioning tests: Gate signal integrity, partial-discharge checks where applicable, and thermal imaging under load during trial runs.

Quality & Certifications

- Manufactured under ABB quality systems (typically ISO 9001)

- RoHS compliance in most cases for semiconductor devices (confirm per lot)

- Device-level CE/UL marking may not apply to discrete semiconductors; system-level compliance required

- Standard 12‑month warranty through our channel

Supporting Components We Can Supply

- Matched IGCT gate units and fiber/auxiliary cabling

- Press-pack clamps, heat sinks, and thermal interface materials

- Snubber capacitors/resistors rated for MV use

- Current/voltage sensors and protection hardware for MV converters

Reviews

There are no reviews yet.