Description

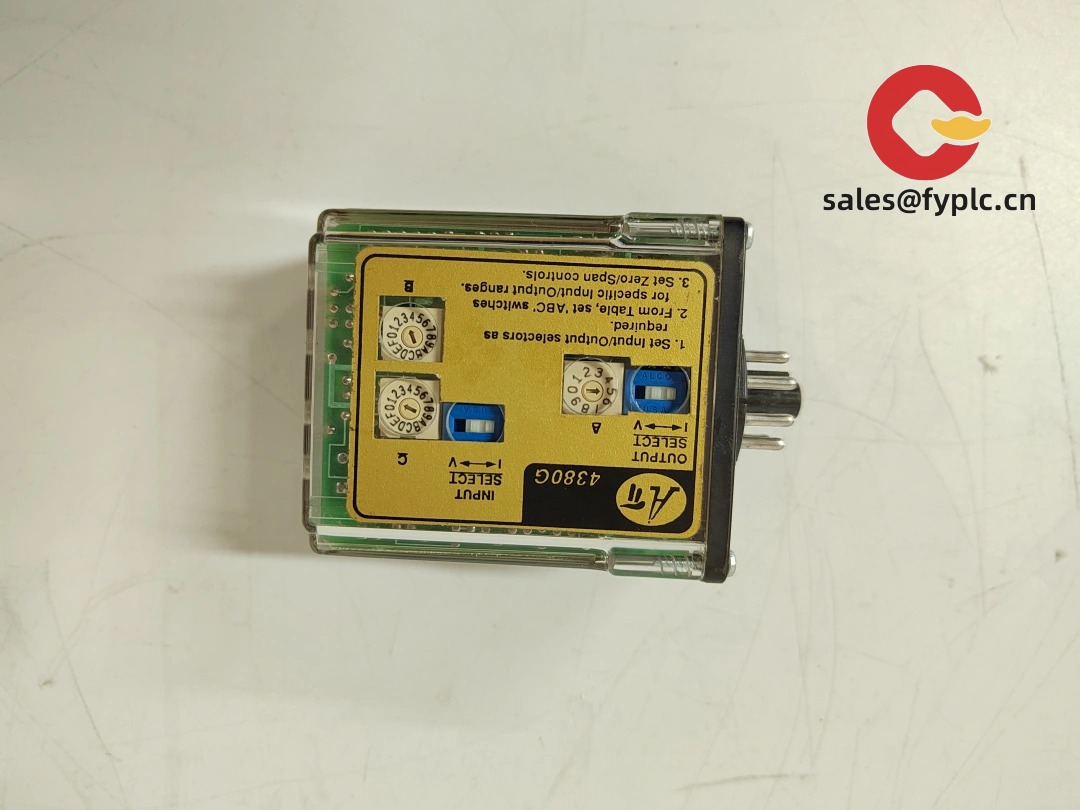

ABB ABSOLUTE-API4380-G – Absolute Position Interface for precise motion and robotic control

The ABB ABSOLUTE-API4380-G is designed for applications where you need reliable absolute position feedback without the guesswork after power cycles. From my experience, this type of module is typically used between an absolute encoder and a motion controller or robot system, capturing multi-turn position and streaming it to the control side with stable, low-latency signals. You might notice that it’s built for cabinet installation, and it tends to play nicely in brownfield upgrades where keeping the existing drives and adding absolute feedback saves both time and wiring.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment, full payment for delivery

- Express options: FedEx, UPS, DHL

Key Features

- Absolute position capture – Maintains true position data after power loss, reducing homing time and downtime.

- Industrial 24 VDC power – Suited for standard control cabinets; wiring is straightforward and typically tool-free.

- Cabinet-ready form factor – Compact, DIN-rail friendly layout makes retrofit work cleaner and faster.

- Encoder compatibility – Designed for absolute encoders commonly used in ABB motion systems; in many cases you’ll see SSI/BiSS style connections in the field.

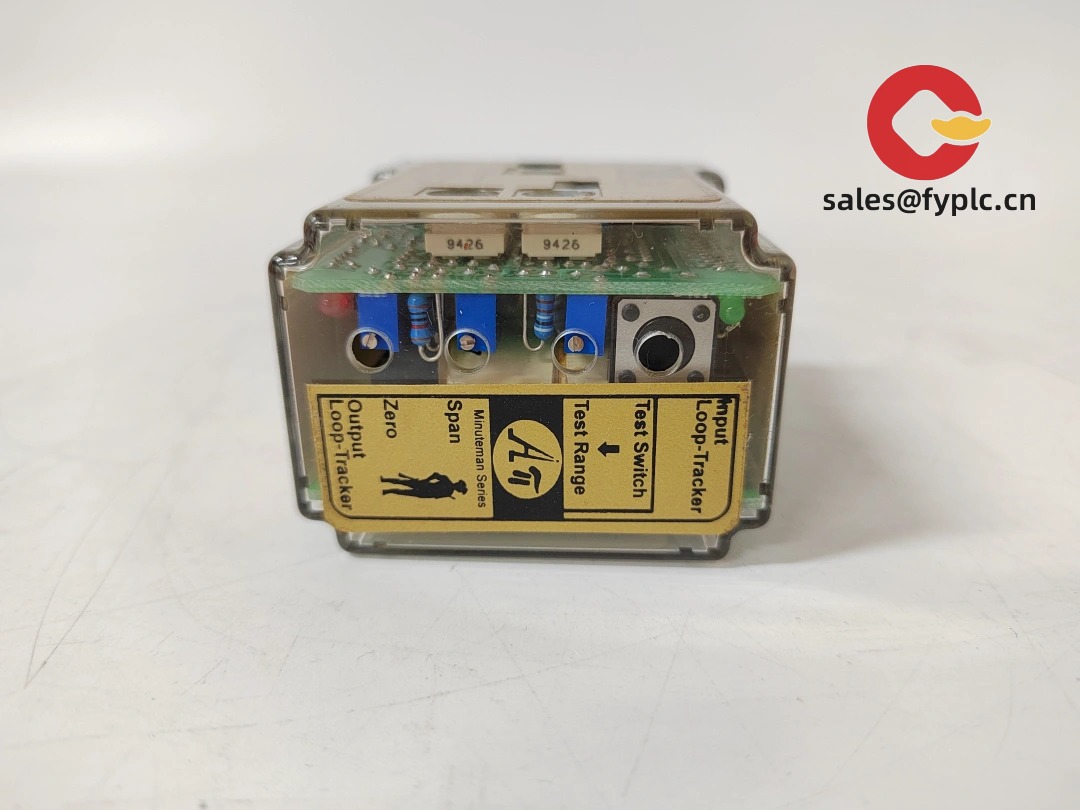

- Diagnostics at a glance – Status LEDs and a simple service interface help maintenance teams pinpoint wiring or encoder issues quickly.

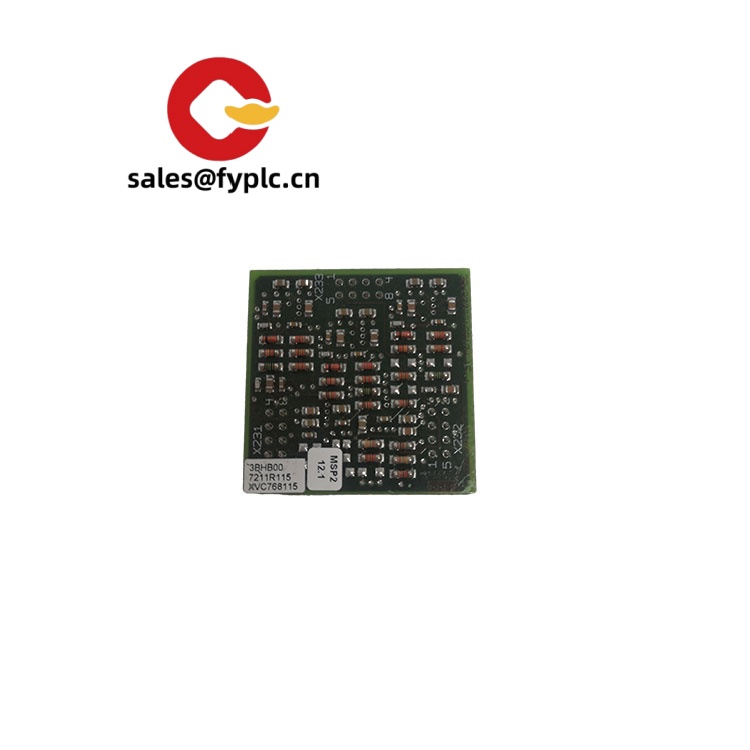

- EMC-hardened design – Built for noisy plant environments, with shield and grounding points that actually make a difference.

- Service-friendly – From what customers tell us, swap time is short and configuration is typically minimal once the encoder type is matched.

Technical Specifications

| Brand / Model | ABB / ABSOLUTE-API4380-G |

| HS Code | 9031.80 (Measuring or checking instruments – reference for absolute position interface devices) |

| Power Requirements | 24 VDC nominal; ripple within typical cabinet standards; low power consumption for dense panels |

| Operating Temperature | Typically −20 to +60 °C (when installed in a ventilated control cabinet) |

| Signal Input / Output Types | Absolute encoder input (commonly SSI/BiSS in many installations); basic digital status outputs for run/fault |

| Communication Interfaces | Service/diagnostics port (maintenance use); controller-side signals per system integration |

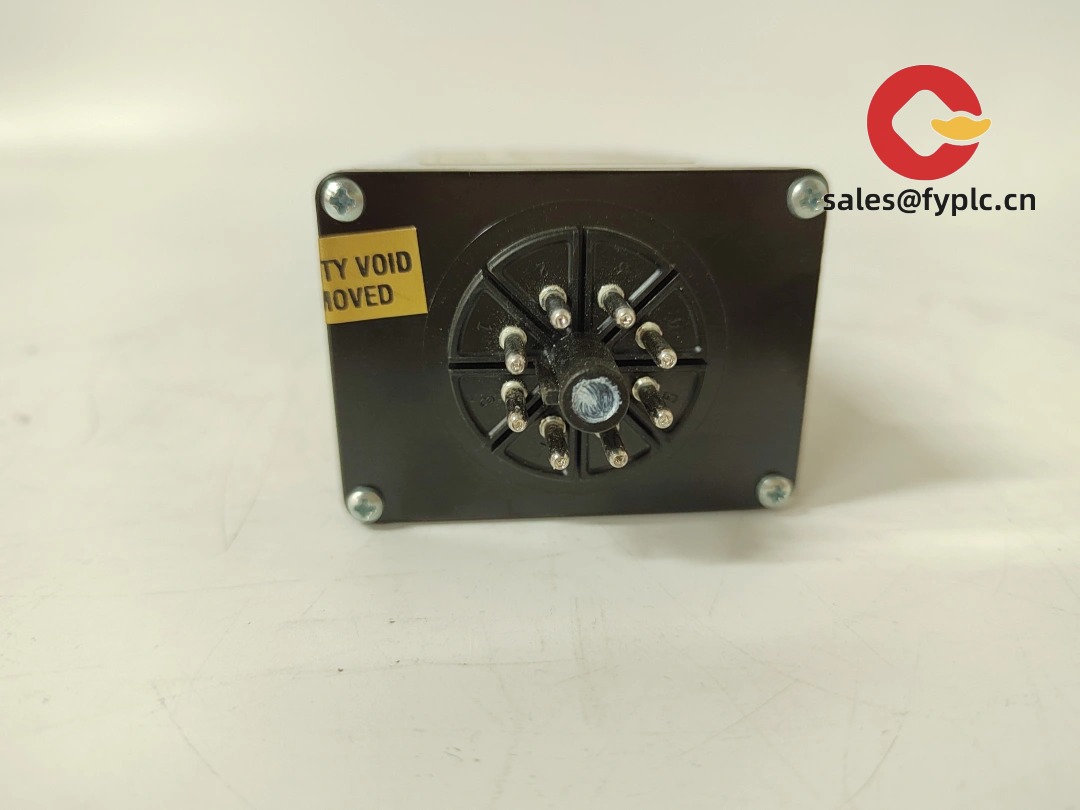

| Installation Method | DIN-rail or panel mounting inside control cabinet (IP20 environment) |

| Dimensions & Weight | Compact cabinet module; detailed drawing available on request |

Application Fields

This module fits where precise position is non‑negotiable:

- Robotic cells and positioners needing true multi-turn position after shutdown

- Servo-driven packaging, pick-and-place, and infeed synchronization

- Material handling, AGV docking, and automated storage systems

- CNC axes, rotary index tables, and high-accuracy linear stages

- Modernizations of legacy lines where adding absolute feedback improves OEE

Advantages & Value

- Reliability – Stable absolute feedback reduces homing routines and recovery time after E-stops or outages.

- Compatibility – Works with widely used absolute encoders; in many cases you can reuse existing sensors and cables.

- Cost control – Retrofit-friendly design avoids full controller swaps; wiring and commissioning stay lean.

- Service support – Clear diagnostics make life easier for maintenance crews; fewer callouts and faster MTTR.

Installation & Maintenance

- Cabinet standards – Install in an IP20 control cabinet with adequate ventilation; follow EN 60204‑1 wiring practices.

- Power & grounding – Use a clean 24 VDC supply, proper PE grounding, and keep encoder shield bonded at a single point to reduce noise.

- Cabling – For absolute encoders, shielded twisted pairs are recommended; route encoder cables away from VFD outputs and contactors.

- Safety – De-energize the panel before wiring; verify encoder pinout and polarity to avoid sensor damage.

- Routine care – Periodically check terminal torque, cable shields, and enclosure dust; update firmware when advised by the manufacturer.

Quality & Certifications

- CE conformity and RoHS compliance are typical for ABB cabinet modules

- UL/CSA recognition is commonly available for North America

- Manufactured under ISO 9001 quality systems

- Warranty: 12 months from shipment

Helpful accessories and supporting components

- 24 VDC DIN‑rail power supplies with low ripple for encoder electronics

- Shielded encoder cables and mating connectors (SSI/BiSS style as required)

- DIN‑rail grounding terminals and EMC cable glands for clean shielding

- Panel label kit and wiring markers to simplify future service

Field note: A maintenance lead at a food & bev site mentioned they swapped a failed interface and had the line running again in under 30 minutes—no re-homing step needed. That’s the kind of little win that adds up across a shift.

Reviews

There are no reviews yet.