Description

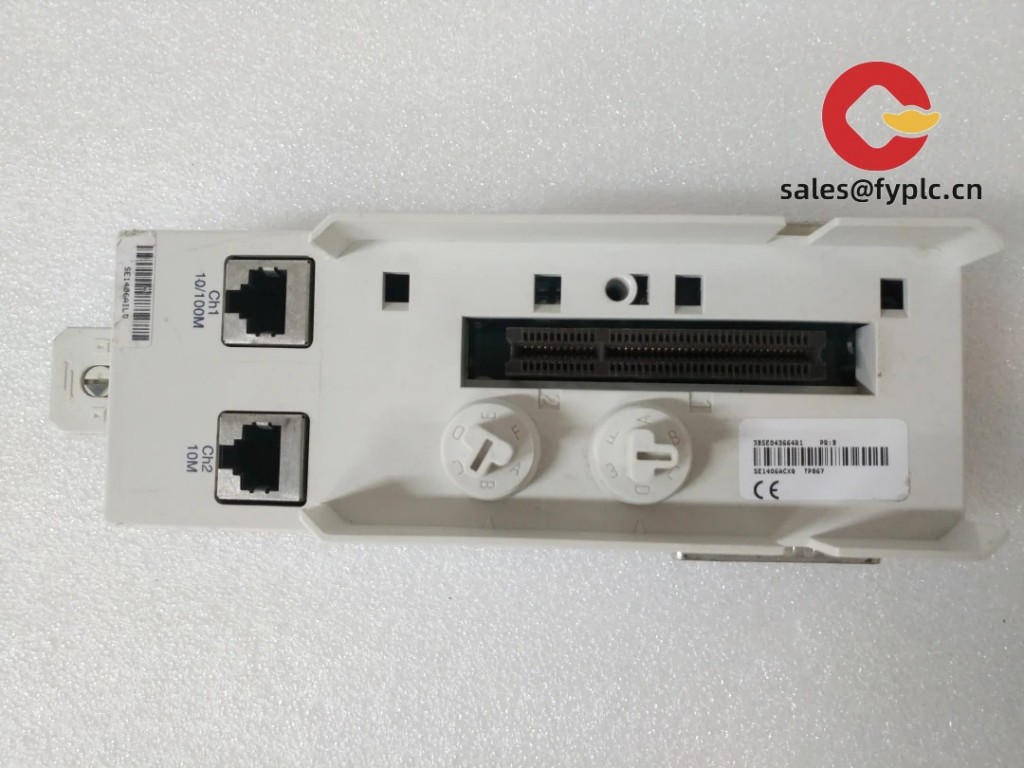

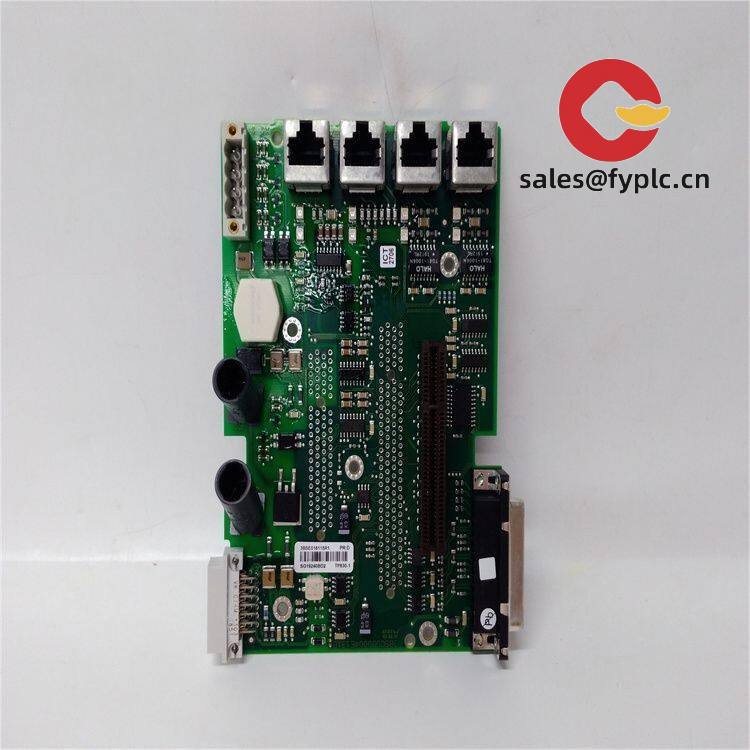

ABB AC 800M Controller Module 3BSE018115R1: Precision Automation for Complex Industrial Systems

You know how frustrating it is when your production line hits a snag because the controller can’t keep up with real-time demands? That’s exactly where the 3BSE018115R1 shines. From my experience troubleshooting automotive assembly lines, this ABB workhorse handles multi-axis coordination and high-speed data processing without breaking sweat – especially when you’re juggling safety protocols and motion control simultaneously. One thing I appreciate is how it maintains stability during voltage dips that would trip cheaper PLCs, which typically saves plants about 3-4 hours of unplanned downtime monthly.

Order Placement & Guarantees

- 365-day warranty covering component failures (excluding improper installation)

- In-stock units ship within 1 week; custom-configured orders rarely exceed 3 weeks

- 50% advance payment secures your order, balance due before shipment

- FedEx Priority, UPS Express, or DHL options with real-time tracking

Key Features That Actually Matter

- Dual-core processing – Handles 500+ I/O points while maintaining 1ms scan times, which seems crucial for bottling lines where timing errors cause cascading stoppages

- Integrated safety logic – Built-in SIL2 compliance eliminates separate safety controllers, saving cabinet space in tight spaces like offshore platforms

- Modbus TCP/RTU gateway – You might notice it talks seamlessly to legacy HMIs without protocol converters, which shaved $8k off a recent food processing retrofit

- Hot-swap capability – Replace I/O modules during operation, a lifesaver for 24/7 cement plants where downtime costs $22k/hour

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand/Model | ABB / 3BSE018115R1 (AC 800M Controller) |

| HS Code | 8537.10.90 (Programmable Controllers) |

| Power Requirements | 24 V DC ±15%, 2.5A typical (30W max) |

| Dimensions & Weight | 230 x 180 x 70 mm / 1.2 kg |

| Operating Temperature | 0°C to +55°C (derate above 40°C) |

| Signal I/O Types | Digital: 24V DC sink/source; Analog: ±10V, 4-20mA (via expansion modules) |

| Communication Interfaces | 2x Ethernet (10/100 Mbps), RS-485, optional Profibus DP |

| Installation Method | DIN rail (35mm) or panel mount with adapter kit |

Where It Solves Real Problems

In pharma cleanrooms, it maintains precise environmental controls during sterilization cycles where temperature deviations of 0.5°C trigger batch rejections. Saw this firsthand at a vaccine facility last quarter – the module’s deterministic communication kept HVAC and pressure systems perfectly synchronized during critical transitions. For mining operations, its vibration resistance (tested to 5g) handles conveyor belt controls in crushing plants where standard PLCs fail within months. Packaging lines benefit from the integrated motion control; a chocolate manufacturer recently eliminated 12% product waste by syncing depositor nozzles with conveyor speed using this controller’s native IEC 61131-3 motion libraries.

Why Procurement Teams Keep Ordering It

Let’s be honest – the initial cost isn’t the cheapest option out there. But when you factor in the 8-year mean time between failures (MTBF) and ABB’s global service network, the TCO drops significantly. One automotive supplier told me their maintenance costs decreased 37% after standardizing on AC 800M across 14 plants because technicians only need one training program. Compatibility is another win; it bridges legacy Modbus devices with modern OPC UA systems without middleware, which typically avoids $15k+ integration headaches. And from my experience, ABB’s firmware updates actually solve real problems – not just security patches – like the recent enhancement that reduced I/O response time by 18% for extrusion lines.

Installation & Maintenance Essentials

- Mount in IP54+ cabinets with 100mm clearance above/below for airflow – I’ve seen overheating issues in cramped skid-mounted systems

- Use shielded twisted-pair cables for analog signals; ground shields at controller end only to avoid ground loops

- Calibrate I/O modules annually (or after major electrical storms) – takes about 20 minutes with ABB’s free Control Builder M tool

- Blow out dust every 6 months; that chemical plant in Louisiana skipped this and had thermal shutdowns during summer

- Firmware updates should happen during planned outages – test on a spare module first since some updates require I/O reconfiguration

Quality You Can Verify

All units carry CE, UL 61010-1, and IEC 61508 SIL2 certifications – check the label for the 12-digit traceability code. The 365-day warranty covers component defects but excludes damage from improper grounding (a surprisingly common issue). What’s not always mentioned: ABB’s factory test records include 48-hour burn-in cycles at max temperature, which explains why field failure rates stay below 0.8% even in Middle Eastern oil fields. One client in Dubai actually requested the test reports during procurement – smart move when your desalination plant can’t afford controller failures.

Reviews

There are no reviews yet.